- The paper's main contribution is a computational framework that integrates high-fidelity CFD simulations with a learning-based RCAC adaptive PI controller for precise thrust regulation.

- It employs a multi-fidelity CFD model that accurately captures shock, boundary layer, and unstart dynamics, facilitating rapid prototyping of control strategies.

- The adaptive PI controller tunes gains in real time without requiring an explicit reduced-order model, ensuring robust performance under nonlinear and underactuated conditions.

Computational Modeling and Adaptive Control of Solid-Fuel Ramjets

Introduction

This paper presents a fully integrated computational and learning-based control framework for thrust regulation in solid-fuel ramjets (SFRJs), a propulsion architecture characterized by strong nonlinearities, severely underactuated dynamics, and complex multi-physics coupling between fuel regression, combustion, and compressible flow. Two core components form the backbone of the approach: (1) a computational fluid dynamics (CFD) model that captures the thrust and operational envelope (including the onset of unstart), and (2) a learning-based, adaptive proportional–integral (PI) controller synthesized via retrospective cost adaptive control (RCAC), which iteratively tunes control gains based on measured performance, obviating the need for an explicit reduced-order model.

Multi-Fidelity CFD Modeling of SFRJs

Model Architecture

The SFRJ is modeled as a 2D axisymmetric domain with an inlet, combustor, and exit nozzle based on experimental geometries in the literature. The governing equations are the fully compressible Navier-Stokes equations, closed with a perfect gas equation of state, discretized using the median-dual finite-volume method in SU2 [economon2016a]. Turbulence is addressed via the k−ω SST model. Combustion is emulated through a specified isobaric wall heat flux (representing enthalpy addition by fuel regression), bypassing the need for detailed multi-step chemical kinetics.

Boundary conditions enforce supersonic inflow (Mach 2, p=105 Pa, T=300 K) and supersonic outflow. The axisymmetry and mesh resolution (approximately 60,000 unstructured cells) are validated by grid convergence studies.

Figure 1: Computational mesh consisting of approximately 60,000 unstructured cells.

Geometry and Flow Regimes

The geometry selected facilitates systematic analysis of combustor and inlet stability, particularly with respect to unstart. The step-wise combustor enables the emergence of subsonic, choked, and supersonic regions in the core flow depending on heat addition.

Figure 2: Simplified SFRJ geometry.

Model Fidelity and Resource Constraints

A fidelity hierarchy was used to balance cost against predictive accuracy (see Figure 3).

Figure 3: Different fidelities to investigate SFRJs where accuracy comes at the cost of resources.

Low-fidelity models support rapid prototyping of control policies, while high-fidelity CFD simulations are used for realistic evaluation of thrust modulation, dynamic loading, and unstart.

Thrust and Unstart Dynamics

Steady-state parametric sweeps over heat flux levels (2-16 MW/m2) revealed critical behavior in SFRJ thrust. Up to approximately 12 MW/m2, thrust increases monotonically with heat flux; further increases abruptly induce a collapse in thrust due to inlet unstart triggered by thermal choking and a transition from supersonic to subsonic inlet conditions.

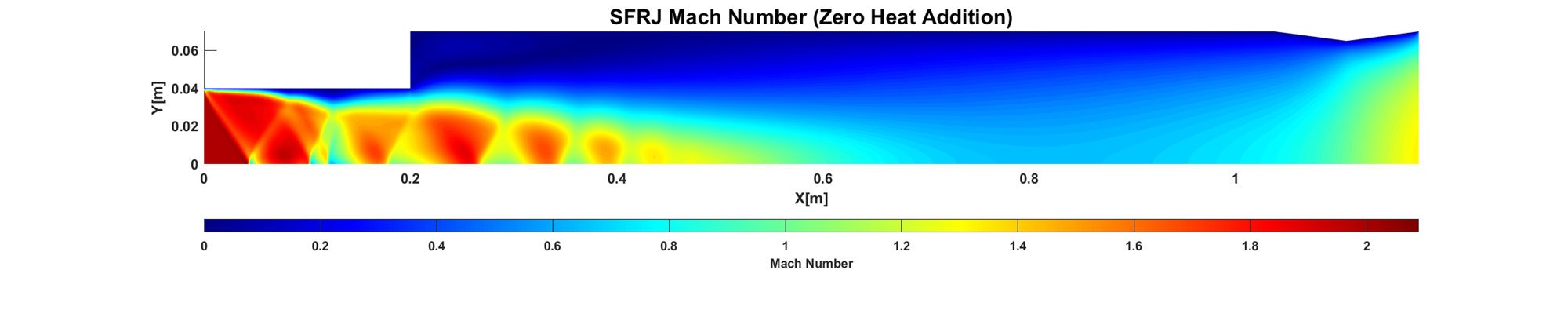

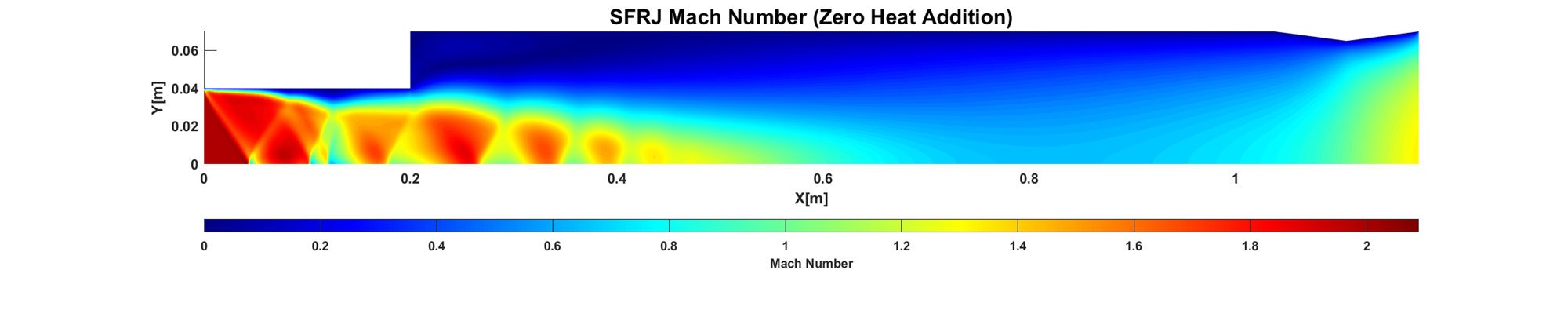

Figure 4: Mach number contour for SFRJ with no heat addition.

Figure 5: Mach contour before unstart.

Figure 6: Without heat addition.

These results are quantitatively consistent with 1D isentropic theories of heat addition to subsonic/supersonic flow, but the CFD model enables fidelity in the prediction of shock, boundary layer, and separation features critical for practical control synthesis.

Adaptive PI Control via RCAC

Control Architecture

The learning-based control architecture consists of an adaptive PI controller with gains (KP,k, KI,k) updated in real time by RCAC. The controller acts on the thrust-tracking error zk and integrates output error γk, with control action mapped to heat flux via an affine transform calibrated to maintain signal scaling appropriate for RCAC numerical stability.

A regressor-based formulation is used, with the control input at each time step: uk=KP,kzk+KI,kγk.

The RCAC update solves a retrospective cost minimization problem, requiring only logged data of zk, uk, and measured thrust yk, with no need for a linearized or reduced-order SFRJ model.

Features of RCAC

The RCAC algorithm provides:

- Model-free adaptation: Hyperparameters can be chosen in a wide range without significant degradation in tracking performance, as shown in extensive sweep studies.

- On-line learning: The controller adjusts gains in real time as the SFRJ system dynamics change, including during rapid transitions in inlet conditions or thrust commands.

- Generalizability across fidelities: Controllers tuned on low-fidelity models retain closed-loop performance on higher-fidelity simulations, thanks to the adaptive learning layer.

Static and Dynamic Operating Scenarios

Closed-loop simulations for static setpoint tracking (e.g., $600$ N constant thrust) demonstrate rapid convergence of the output error to zero, and exponential stability is maintained even when exposed to randomized step commands and operating point changes.

The controller maintains high accuracy across a broad range of inlet Mach numbers, pressures, and temperatures (sampled from practical flight altitudes/velocities). The PI gains are observed to adapt on-the-fly to each scenario, indicating the algorithm's ability to cope with parametric uncertainty and unmodeled plant dynamics.

Integrated Guidance, Dynamics, and Real-Time Control

Scenario: In-Flight Missile Engagement

A full six-degree-of-freedom, vertically planar, missile–target interception scenario was constructed. The SFRJ is responsible for thrust maintenance while the missile undergoes time-varying (h,M) due to maneuvering. A constant-thrust guidance law assumes fixed propulsion; the adaptive controller is tasked with enforcing this assumption under real, time-varying inflow conditions.

The results demonstrate the ability of the RCAC-based controller to track demanding thrust commands (e.g., 12 kN) with minimal error, even as inflow properties varying along the engagement envelope would cause significant open-loop thrust perturbation. Without adaptation, failure to regulate would violate guidance assumptions and degrade intercept performance.

Numerical Results, Tradeoffs, and Limitations

Computational Demand

- The high-fidelity axisymmetric CFD model requires nontrivial computation (hours per scenario at this mesh resolution); lower-fidelity models are necessary to prototype controllers rapidly.

- Closed-loop adaptation, however, does not significantly impact computational cost due to the low-dimensional nature of the controller update equations.

Fidelity versus Controller Robustness

- Increasing model fidelity yields improved physical reliability but does not guarantee improved control performance; data-driven adaptive policies, as shown here, render high-fidelity models most useful as testbeds rather than as sources for model-based controller synthesis.

- High-fidelity models remain indispensable for predicting unstart and off-nominal combustion effects, and for evaluating failure scenarios otherwise inaccessible to analytical models.

Limitations

- The combustion model uses a greatly simplified heat-flux boundary rather than multi-species, finite-rate reactions. Future work will implement detailed chemistry (SU2-NEMO/Mutation++), which will allow direct modeling of pyrolysis, regression, and flame structure and better capture transient phenomena and localized instabilities.

- All results are based on simulations; experimental hardware validation remains an outstanding step before deployment.

Implications and Future Directions

This integration of model-free, online learning-based thrust control with CFD-based SFRJ simulation platform represents a substantial step toward addressing the core practical problem of robust thrust regulation under uncertainty and severe nonlinearity characteristic of air-breathing solid-fueled missiles. The demonstrated performance under significant disturbances and in engagement scenarios where thrust tracking is mission-critical provides compelling evidence for the suitability of RCAC and related learning-based controllers in future air-breathing platforms.

The results indicate a path forward for the synthesis and deployment of adaptive control architectures in settings characterized by complex, expensive computational models and incomplete physical understanding. Possible future developments include:

- Integration of multi-fidelity and multi-physics surrogates for rapid controller prototyping.

- Extension of the RCAC framework to multi-variable and distributed actuation systems with additional sensor feedback (e.g., chamber pressure, wall heat flux).

- Hardware-in-the-loop and experimental demonstration of closed-loop, learning-based thrust regulation under combustion instability and aging fuel regression conditions.

- Incorporation of model uncertainty quantification and output constraints directly into the adaptive law for reliable operation near unstart boundaries.

Conclusion

This work presents a rigorously validated CFD and control framework that fuses high-fidelity SFRJ simulation and robust, learning-based adaptive thrust regulation. The approach provides precise, model-free thrust control under a wide range of practical operating conditions, leveraging real-time adaptation to manage the nonlinear, coupled physics and strong parametric uncertainty inherent to SFRJs. These results indicate that learning-based adaptive control systems will be central to the deployment of reliable solid-fuel ramjet propulsion for high-speed, long-range flight systems, making possible robust operation in environments previously inaccessible using model-based strategies alone.