- The paper demonstrates programmable stiffness via toggleable bistable unit cells that switch discrete states under shear loading.

- Finite element analysis and theoretical modeling reveal that support beam slenderness and hinge placement critically modulate stiffness ratios.

- Experimental and device-level tests confirm state-dependent mechanical behavior, paving the way for applications in soft robotics and adaptive structures.

The paper "Toggling stiffness via multistability" (2510.09511) presents a comprehensive study of a class of mechanical metamaterials that exhibit discrete, switchable stiffness states through multistability. The work combines theoretical modeling, finite element analysis, experimental validation, and device-level demonstration to elucidate the mechanisms underlying toggleable stiffness and to establish a design methodology for programmable mechanical response in soft systems.

Mechanism of Toggleable Stiffness

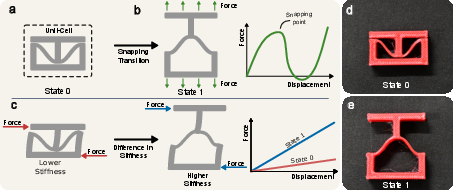

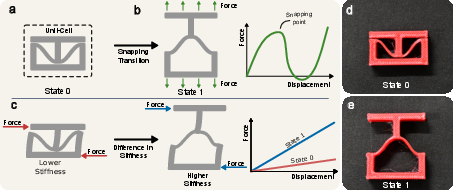

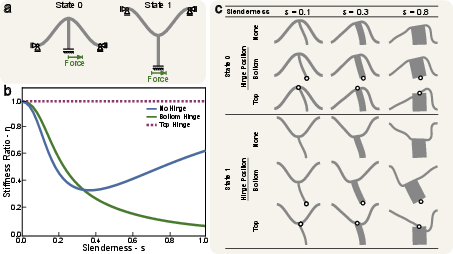

The core innovation is the design of a bistable unit cell composed of a curved beam (parametrized as the first Euler buckling mode) attached to a frame via vertical support beams. The unit cell exhibits two stable configurations (State 0 and State 1), which can be toggled by snap-through under tension. The key finding is that the effective shear stiffness of the unit cell is state-dependent: the structure is significantly stiffer in State 1 (the higher, metastable configuration) than in State 0.

Figure 1: Conceptual sketch of the toggling stiffness effect, showing bistable unit cell geometries, nonlinear force-displacement behavior, and 3D-printed prototypes in both states.

This counterintuitive behavior is attributed to the transmission of rotation from the support beams to the curved beam under shear loading. The amount of rotation, and thus the difference in stiffness between states, is governed by the slenderness of the support beams and the presence of localized hinges at the beam connections.

Theoretical and Numerical Analysis

Two surrogate beam models are developed to analyze the mechanics of the unit cell:

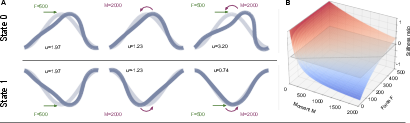

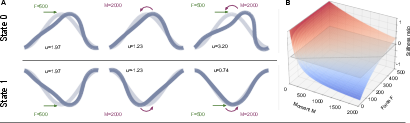

- Model A: Considers only the curved beam, with independent application of horizontal force and bending moment at the center. The direction and magnitude of the moment, which simulates the effect of support beam rotation, are shown to critically affect the stiffness ratio η=k0/k1 between the two states. As the applied moment increases, the stiffness ratio decreases, amplifying the toggleable effect.

Figure 2: Model A results showing deformation patterns and the dependence of stiffness ratio on applied bending moment.

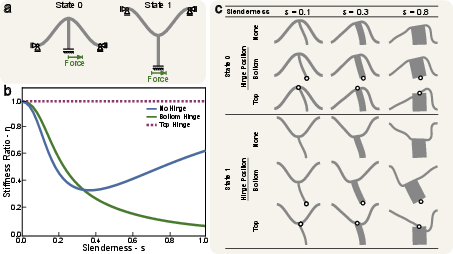

- Model B: Incorporates the support beam explicitly, with horizontal displacement imposed at its lower end. The slenderness parameter s=c/l (width over length) of the support beam is identified as the primary design variable. An optimal slenderness (s≈0.3) maximizes the stiffness ratio, balancing force and rotational transfer.

Figure 3: Model B analysis of the effect of support beam slenderness and hinge placement on stiffness ratio and deformation patterns.

The introduction of localized hinges at the support beam ends further modulates the rotational transfer. A hinge at the curved beam connection suppresses rotation and eliminates stiffness variation (η→1), while a hinge at the frame amplifies the effect, yielding lower stiffness ratios.

Experimental Validation

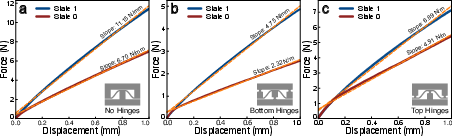

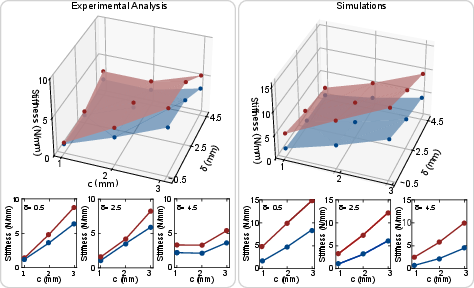

3D-printed two-cell metamaterial specimens are fabricated using FDM with TPU filaments. Mechanical testing under shear confirms the state-dependent stiffness predicted by the models. The effect of support beam slenderness and hinge placement is systematically explored:

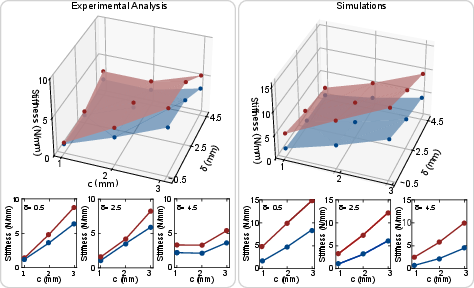

Further, the influence of support beam dimensions (gap δ and width c) is investigated, with both experimental and 3D finite element simulation results demonstrating consistent trends: increased slenderness leads to more compliant behavior and greater stiffness modulation.

Figure 5: Comparison of experimental and numerical results for two-cell metamaterials with varying support beam dimensions.

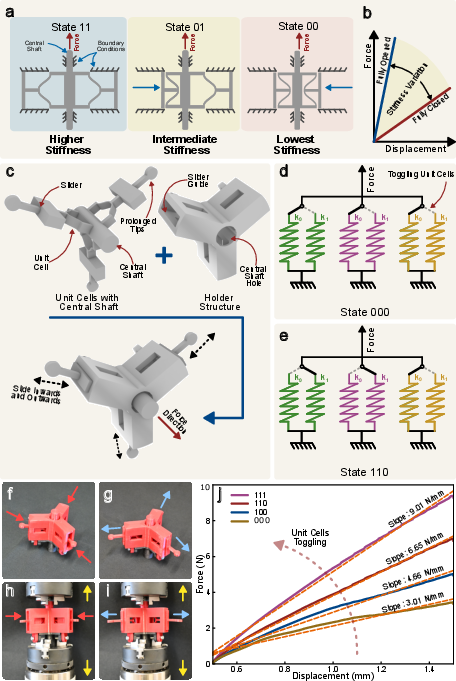

Device Demonstration: Monolithic Soft Clutch

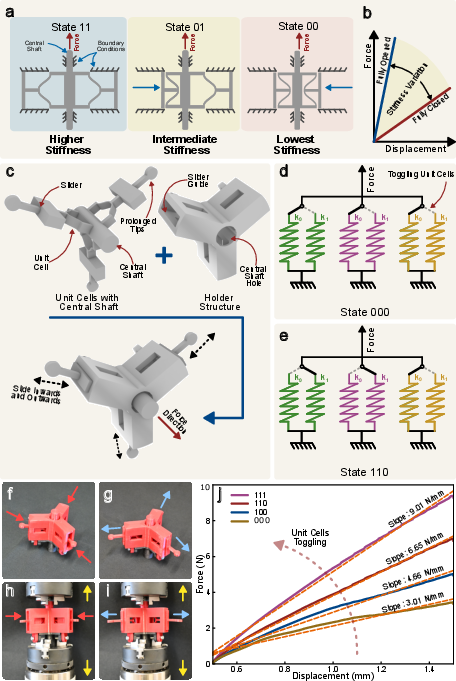

To illustrate the practical utility of toggleable stiffness, a monolithic soft clutch is designed and fabricated. The device consists of three bistable unit cells arranged in parallel, each connected to a central shaft. By toggling the state of each unit cell, the overall device stiffness can be discretely modulated in four steps (000, 100, 110, 111), as confirmed by force-displacement measurements.

Figure 6: Monolithic soft clutch based on toggleable unit cells, showing design, assembly, operation, and force-displacement curves for all state combinations.

The measured equivalent stiffnesses for the four states are 3.01, 4.66, 6.65, and 9.01 N/mm, respectively, demonstrating incremental, programmable stiffness control. Minor deviations from ideal additive behavior are attributed to fabrication imperfections and material variability.

Implications and Future Directions

This work establishes a robust physical and design framework for achieving discrete, programmable stiffness modulation in soft mechanical systems via multistable metamaterials. The findings have several important implications:

- Design tunability: The stiffness ratio and absolute stiffness can be precisely controlled through geometric parameters (support beam slenderness, hinge placement), enabling application-specific optimization.

- Integration potential: The monolithic, soft, and passive nature of the demonstrated clutch device suggests direct applicability in soft robotics, adaptive structures, and vibration control, where variable stiffness is desirable but traditional actuators are impractical.

- Scalability and autonomy: The approach is compatible with scalable fabrication (e.g., 3D printing) and can be extended to arrays of unit cells for higher-order mechanical programmability. Integration with soft actuators could enable autonomous, on-demand toggling of stiffness states.

Theoretically, the work clarifies the role of rotational transfer in multistable architectures and provides a pathway for embedding physical control at the material level, bypassing the need for complex mechatronic assemblies.

Conclusion

The paper provides a detailed mechanistic understanding and practical demonstration of toggleable stiffness in multistable mechanical metamaterials. By leveraging the interplay between support beam geometry and rotational transfer, the authors achieve discrete, programmable stiffness modulation validated by both simulation and experiment. The monolithic soft clutch exemplifies the potential for device-level integration, opening new avenues for adaptive, lightweight, and autonomous systems in soft robotics and smart structures. Future research will likely focus on autonomous actuation for state switching, miniaturization, and integration into multifunctional material systems.