- The paper introduces a novel computational fabrication workflow that transforms flat fabrics into self-folding 3D textiles using embroidered hinges and heat-shrinkable threads.

- It leverages an automated conversion tool based on the Origamizer algorithm to translate 3D models into 2D stitch patterns, achieving a 26/28 success rate.

- The method demonstrates cross-material compatibility and practical applications in fashion and design, paving the way for advanced textile manufacturing.

OriStitch: A Computational Fabrication Workflow

Introduction to OriStitch

"OriStitch: A Machine Embroidery Workflow to Turn Existing Fabrics into Self-Folding 3D Textiles" details a novel approach that combines machine embroidery with computational design to transform flat fabrics into self-folding 3D structures. The method is inherently compatible with a wide range of textile materials, leveraging heat-shrinkable threads and a sophisticated algorithmic process to produce foldable designs.

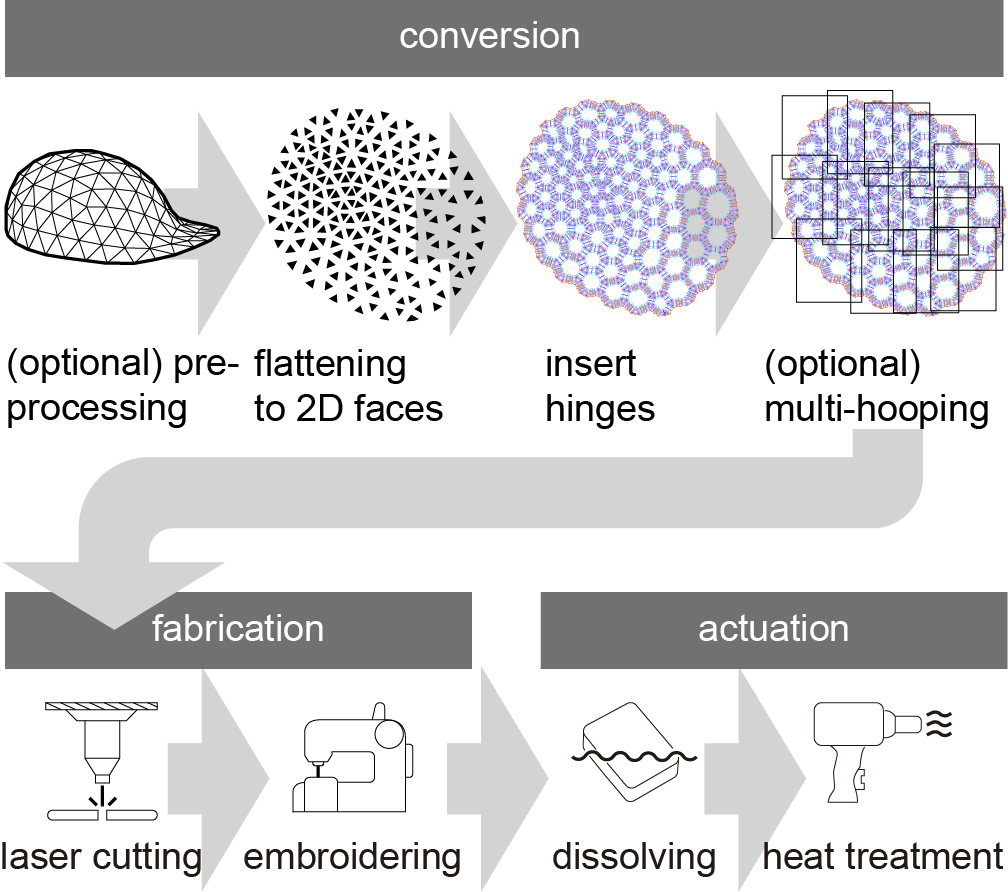

The OriStitch workflow is depicted in the provided overview, illustrating the transformation from flat fabric to a three-dimensional object using embroidered hinges (Figure 1).

Figure 1: An overview of the OriStitch workflow.

Design and Functionality of Embroidered Hinges

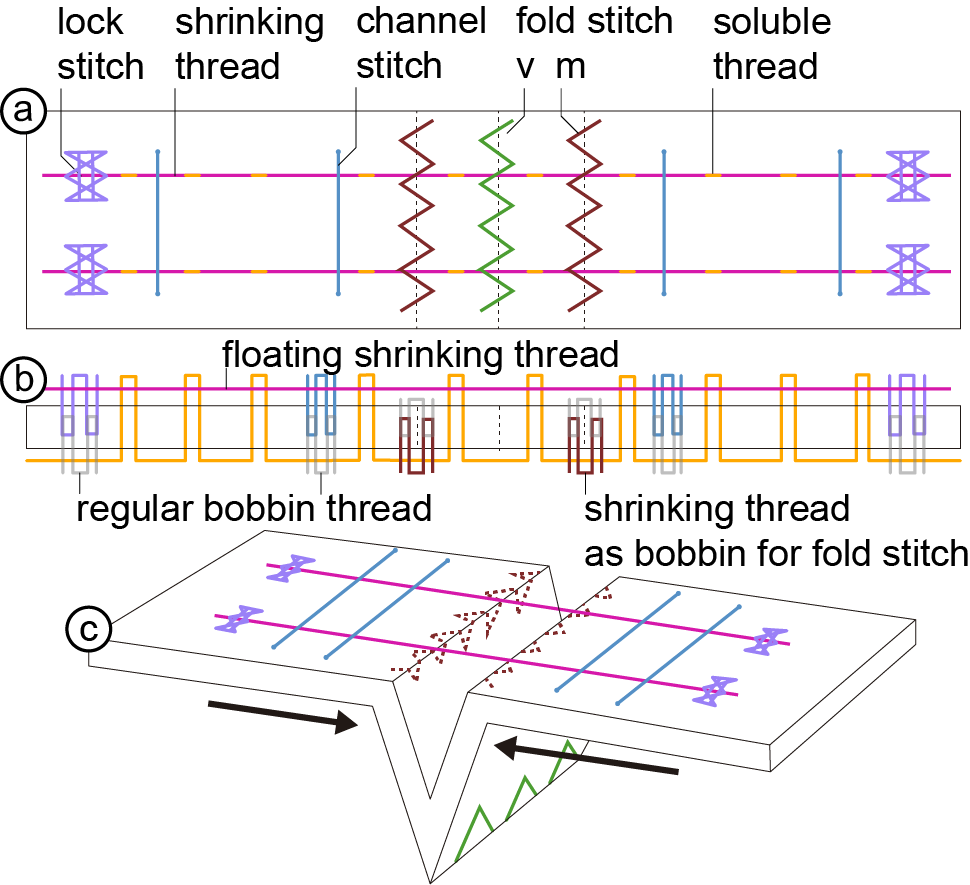

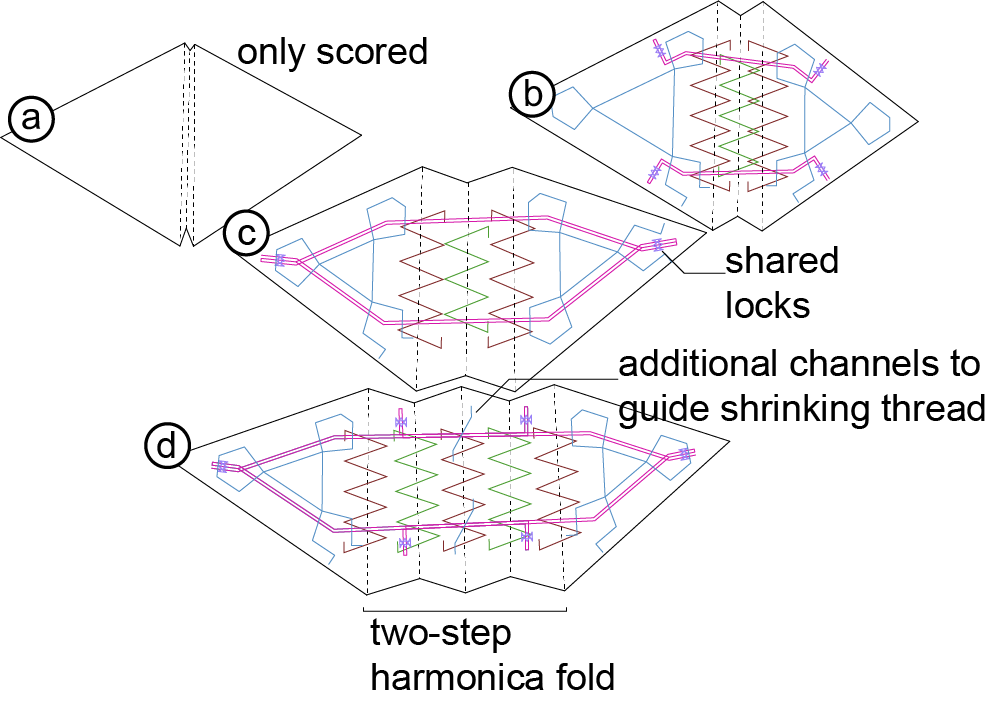

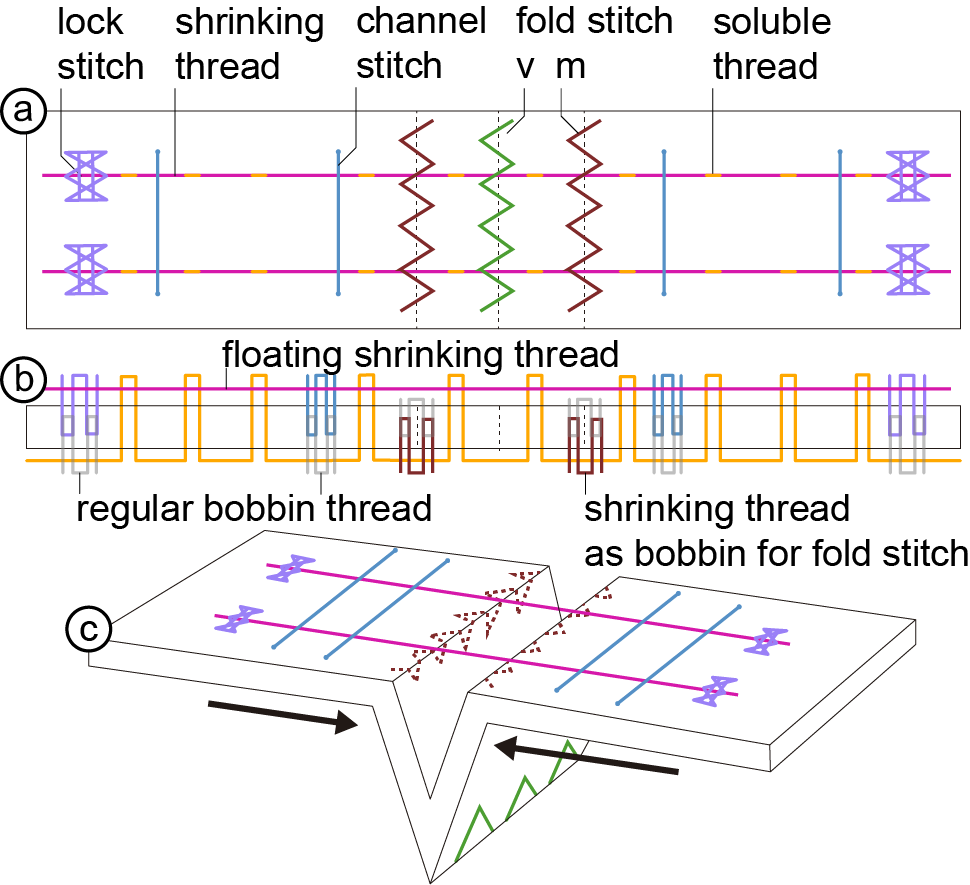

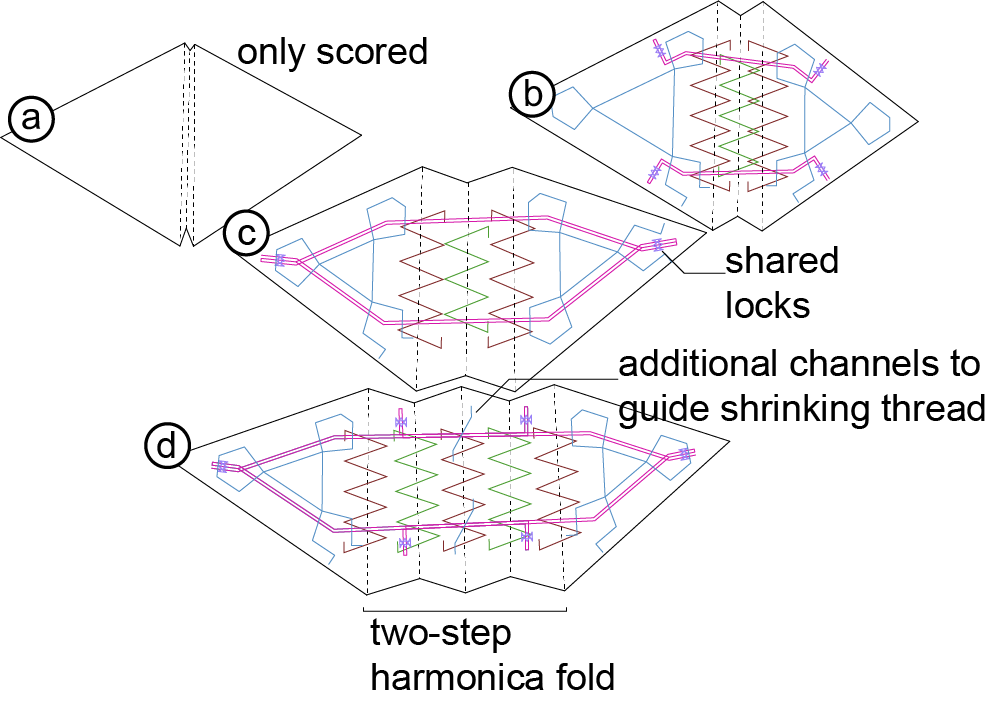

Central to OriStitch is the design of embroidered hinges capable of fully closing under heat exposure. The hinge design relies on a heat-shrinkable polyester thread that contracts significantly when heated (Figure 2). This mechanism enables the folding action necessary to achieve the desired 3D structure from a 2D fabric sheet. The paper introduces four hinge designs to accommodate varying space and folding requirements between fabric faces (Figure 3).

Figure 2: The basic hinge principle, (a)~from above, (b)~from the side, and (c)~when actuated.

Figure 3: Hinge types of increasing width, detailing design variations.

Automatic Conversion and Fabrication Workflow

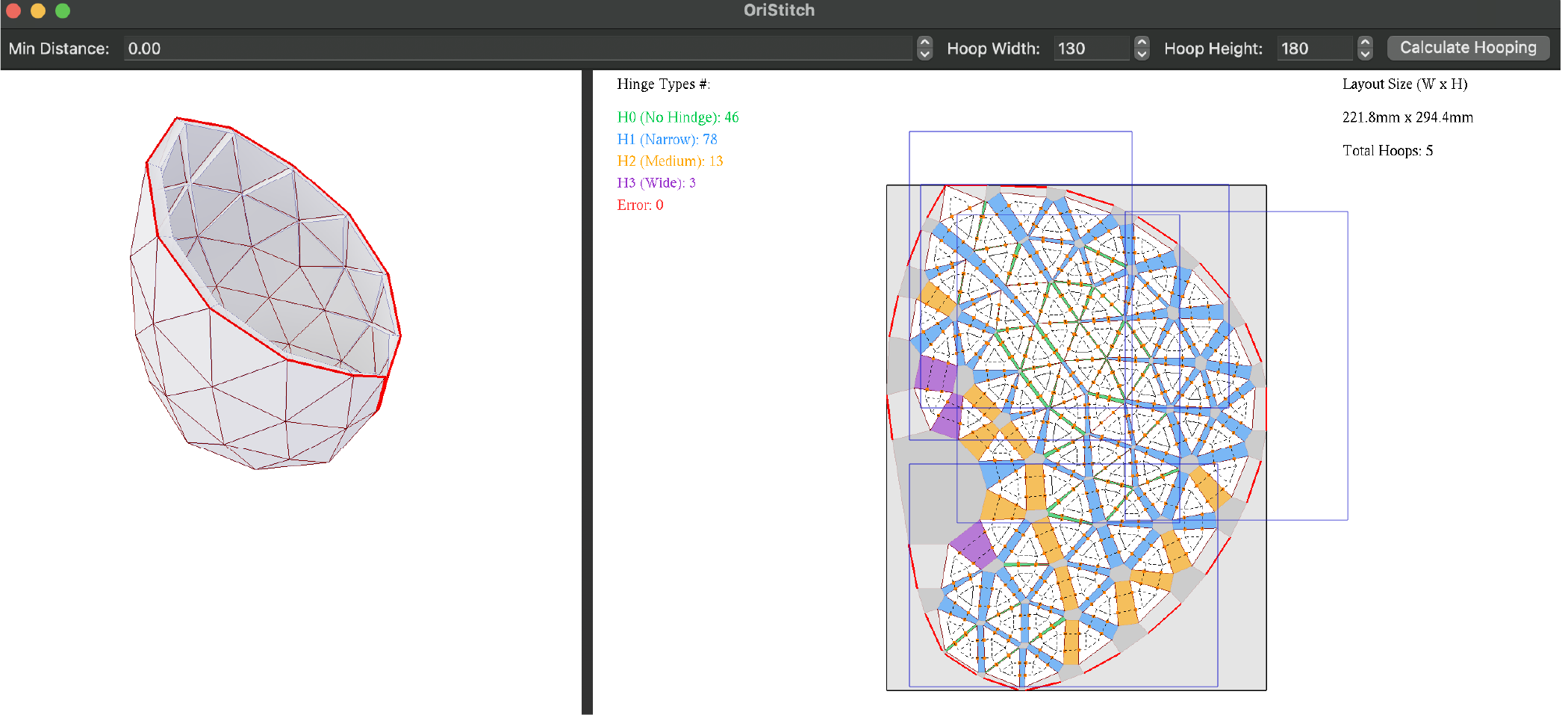

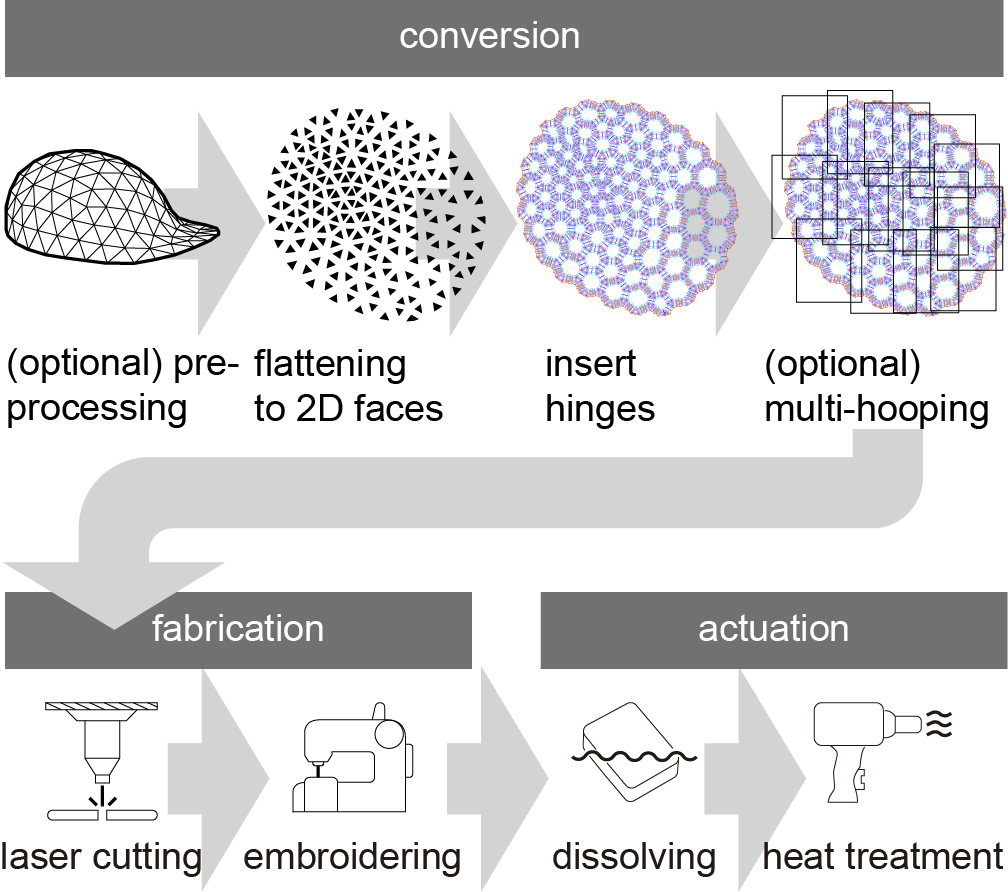

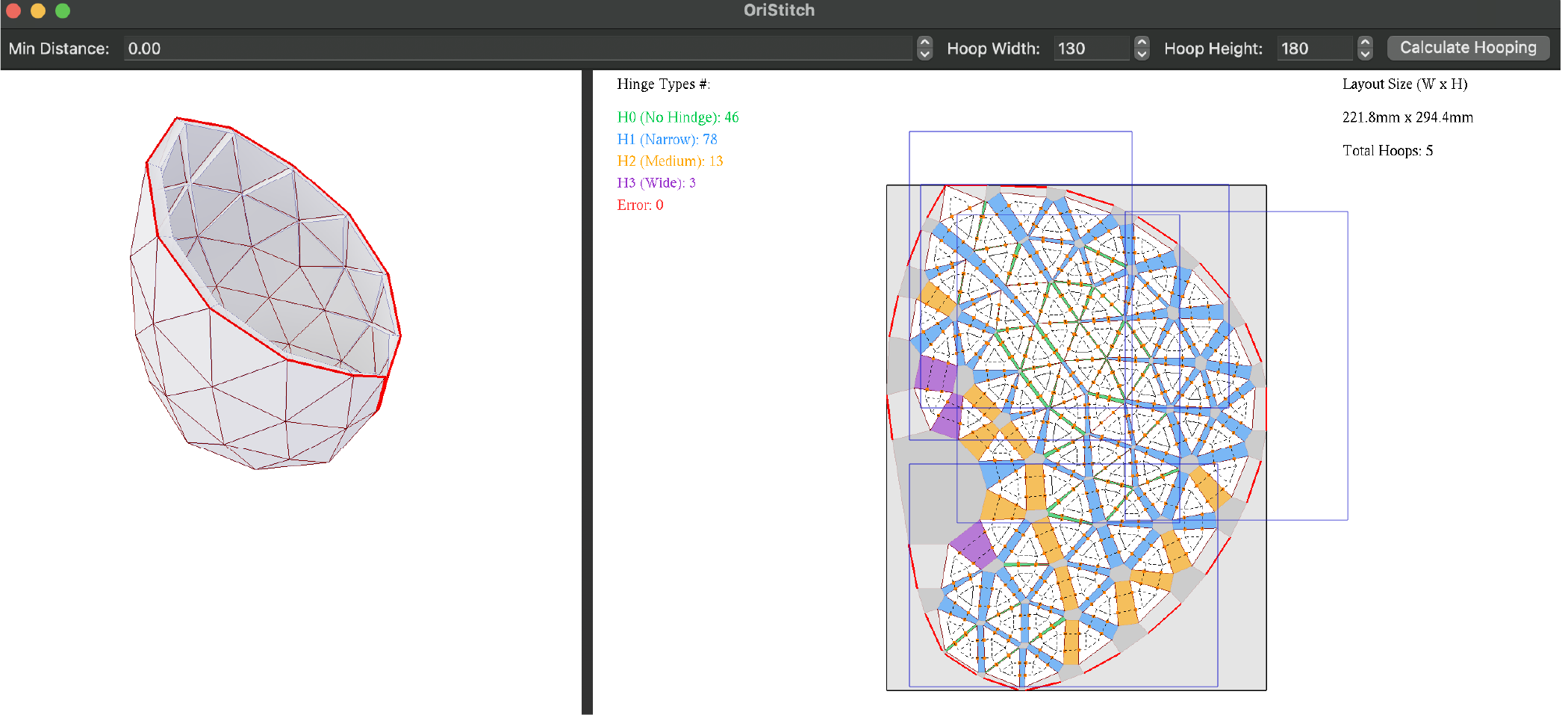

OriStitch integrates a software tool to automate converting 3D mesh models into 2D stitch patterns, facilitating an efficient end-to-end fabrication process. This tool utilizes the Origamizer algorithm to translate complex geometries into stitchable designs, addressing challenges in positioning and hooping (Figure 4).

Figure 4: Users load the OBJ model (left), producing a stitch pattern (right), facilitating layout adjustments.

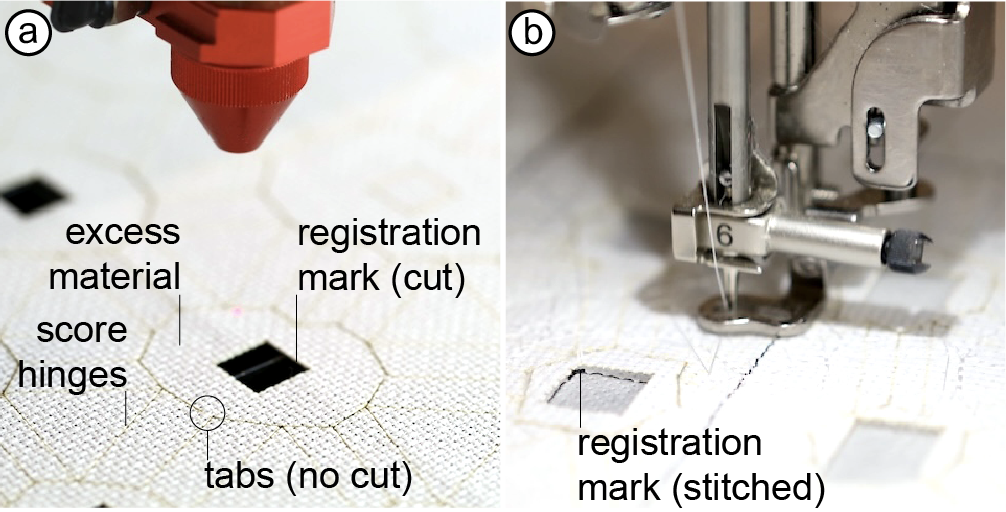

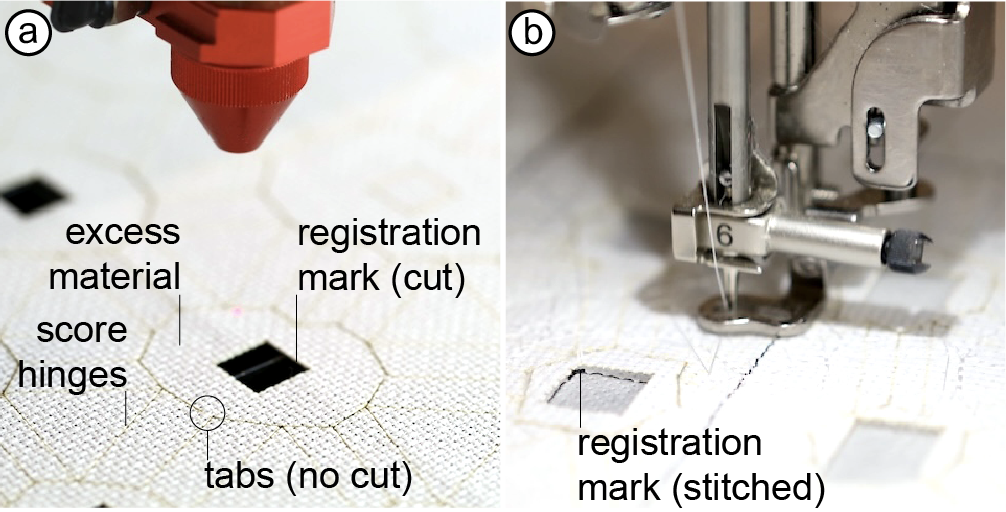

The workflow involves several subprocesses, including the laser cutting of fabric for hinge scoring and pattern cutting, followed by embroidery (Figure 5). The laser cutting ensures precise alignment and facilitates later embroidery processes.

Figure 5: The fabrication workflow with laser cutting and embroidery stages.

Evaluation and Material Compatibility

The evaluation section of the paper underscores the robustness of the OriStitch technique, with a success rate of 26 out of 28 in converting 3D models to stitch patterns. This high compatibility extends across materials like suede, leather, and neoprene, confirming the utility of the method across various textile substrates. This adaptability is crucial for practical applications in fashion and design industries, where material flexibility is often a prerequisite.

Practical Applications and Future Work

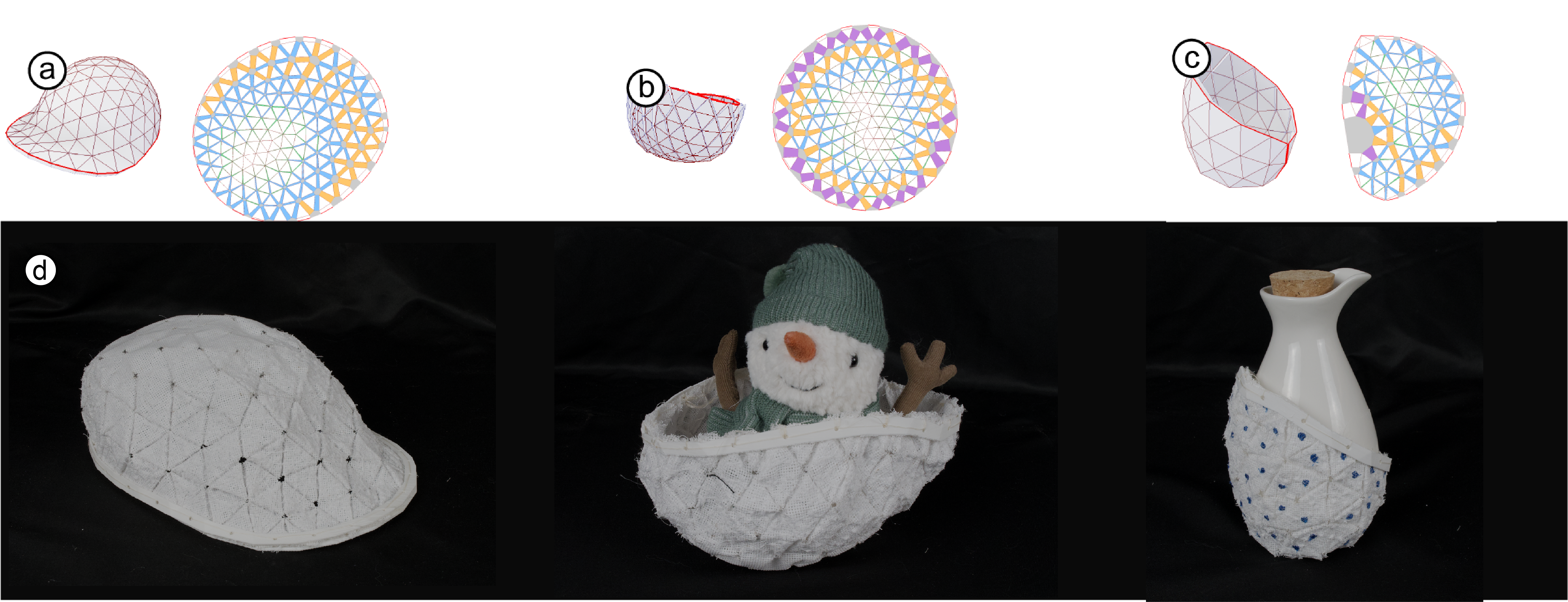

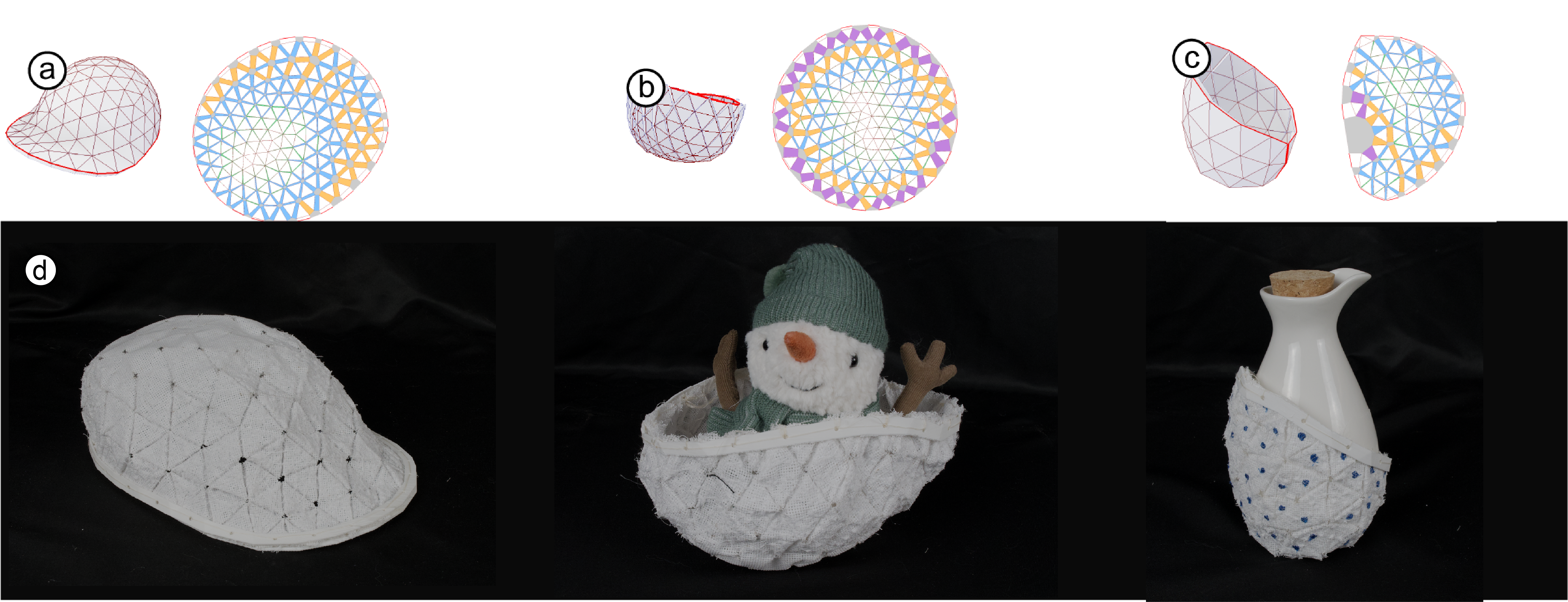

Practical applications demonstrated through OriStitch, such as transforming fabrics into caps, bags, and vase covers, highlight the method's versatility and aesthetic potential (Figure 6).

Figure 6: Application models, showing the transition from digital design to physical artifacts.

The paper suggests that additional research into actuation methods, such as robotic arm usage for heat application, and development of more sophisticated shrinking threads could further augment the system's capabilities.

Conclusion

OriStitch represents a significant advancement in digital fabrication and textile manufacturing, offering a sophisticated and flexible tool for designers seeking to explore complex 3D forms. The automation of the design-to-production process broadens accessibility and encourages innovation across sectors, from high fashion to industrial design. As the technology evolves, OriStitch could play a pivotal role in the broader adoption of computationally-driven textile design.