- The paper presents a novel method for approximating arbitrary 3D shapes with a single developable zippable ribbon, reducing fabrication complexity.

- It employs cylinder-based decomposition and spiral design to map 3D surfaces onto developable meshes with low distortion.

- Results demonstrate practical applications in papercraft and industrial fabrication by streamlining assembly and minimizing errors.

Shape Representation by Zippable Ribbons

Abstract

This paper introduces a novel method for shape representation and fabrication using developable surfaces, specifically through the design and application of zippable ribbons. The approach leverages the concept of zipit bags, which are constructed from a single long ribbon equipped with a zipper. By extending this idea, the authors devise a computational method to approximate arbitrary 3D shapes with a single developable surface, which can be easily fabricated, assembled, and disassembled.

Introduction and Background

In the context of shape fabrication, developable surfaces are surfaces that can be unrolled onto a plane without distortion, which finds numerous applications in fields like papercraft, modern architecture, and CAD. This research builds on the principle used in commercial zipit bags to propose a generalized method for creating zippable 3D shapes. Unlike traditional methods that involve complex assembly instructions and multiple parts, this approach simplifies fabrication to a single ribbon, minimizing the required assembly steps and potential for error.

Cylinder-Based Decomposition

The method begins by decomposing the target 3D shape into a series of topological cylinders. This decomposition is facilitated either by user interactions or through automated methods, allowing each part to be parameterized onto cylindrical domains with low isometric distortion. Seamless mapping across these cylindrical parts ensures that the resulting shape can be approximated with minimal curvature and a constant ribbon width.

Spiral Design and Shape Approximation

Spirals are generated on each cylindrical surface in a manner that ensures uniformity and minimizes curvature, pivotal for the practical application of fabric zippers. The cylindrical parameterization allows for drawing a Fermat spiral on the surface, which can then be traced, cut, and stitched to form the developable ribbon that approximates the target 3D structure.

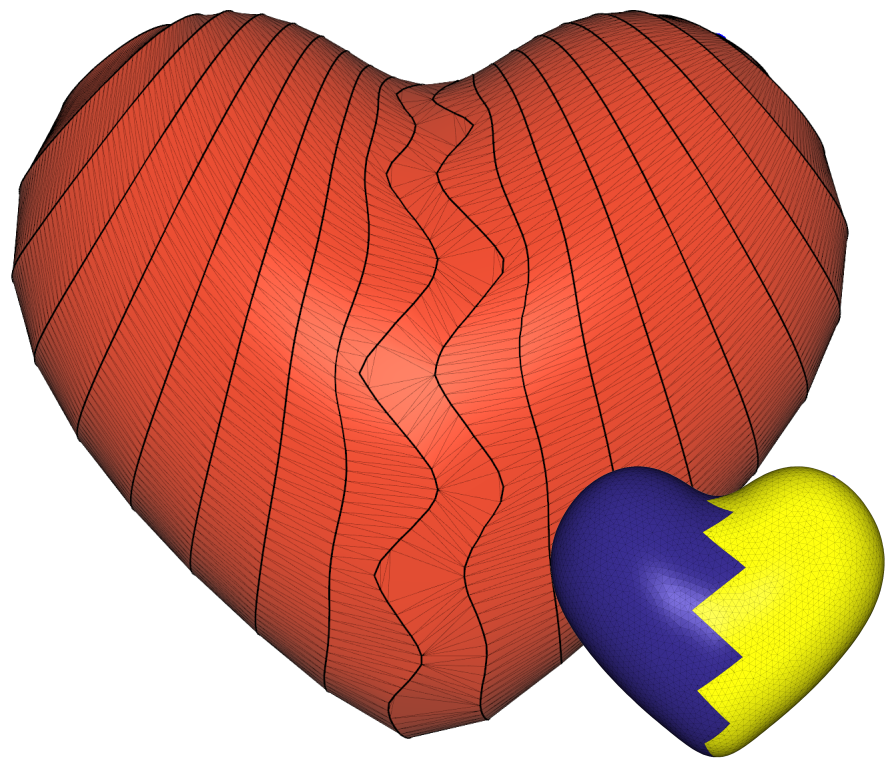

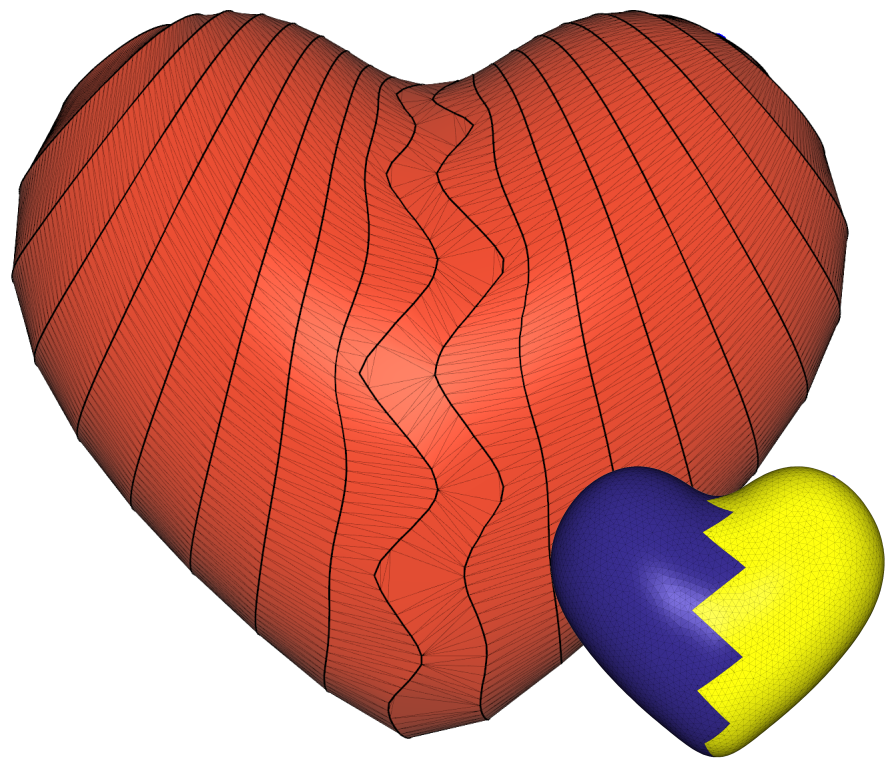

Figure 1: The heart shape is segmented in a zig-zag way to enforce a curved ribbon in the middle of it.

Remeshing and Unfolding

The complex surfaces generated through spiral cutting are transformed into a developable mesh using a process of remeshing, which involves connecting adjacent points on spirals as ruling edges. This mesh is then flattened and prepared for laser cutting, allowing the physical ribbons to be produced from fabric or paper, capable of being zipped and unzipped to form the 3D shape.

Results and Implementation

The paper demonstrates the method on various shapes, ranging from simple to complex designs. The fabricated objects are assembled using a zipper, showcasing the ease and efficiency of the proposed method. The process is computationally efficient, with parameterization optimization converging quickly, even for meshes with substantial complexity.

Practical Applications and Future Work

This method offers significant advantages for fabric-based shape fabrication, where the assembly is reduced to a linear, unambiguous task. The applications extend beyond papercraft and art into practical domains like pipe cladding in insulation processes. Future developments aim to incorporate feature detection for improved shape fidelity and to explore other practical applications and automated fabrication processes.

Conclusion

The research provides a valuable contribution to digital geometry processing and computational fabrication. By reducing 3D model assembly to a single developable ribbon that can be easily fabricated and assembled, the method offers a streamlined, efficient alternative to traditional multi-component fabrication techniques. The future scope includes enhancing design features and exploring practical applications in industrial contexts.