- The paper achieves watt-level SHG efficiency in thin-film LiTaO3 by optimizing electrode geometry, pulse sequence, and spatial layout.

- It establishes a process window that minimizes duty cycle sensitivity and cross-talk, ensuring reproducible quasi-phase matching.

- The work supports scalable integrated nonlinear photonics with superior performance for quantum, telecom, and frequency comb applications.

Watt-Level Second Harmonic Generation in Periodically Poled Thin-Film Lithium Tantalate: Technical Overview

Introduction

This work details the development and optimization of watt-level second harmonic generation (SHG) in periodically poled thin-film lithium tantalate (PPLT). Leveraging improved domain engineering protocols and photonic integration, the paper demonstrates high-power frequency conversion suitable for advanced photonic applications, including wideband frequency combs, quantum transducers, and scalable integrated nonlinear photonics. The paper methodically explores the influence of poling electrode duty cycle, poling pulse sequence, electrode geometry, and spatial arrangement on the domain inversion quality crucial for quasi-phase matched (QPM) SHG.

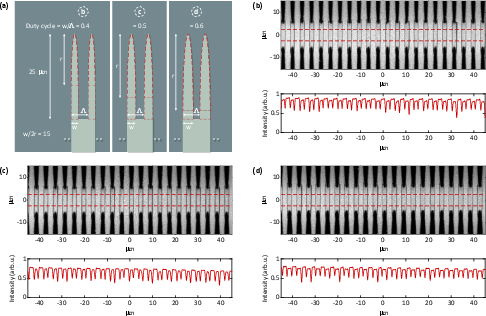

Electrode Duty Cycle and Domain Engineering

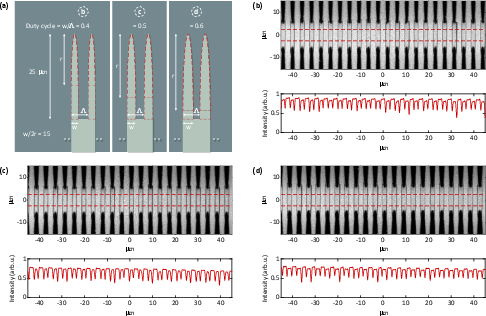

The quality of periodic poling in LiTaO3 is influenced by the duty cycle of the poling electrodes. Optimization focuses on achieving a 50% duty cycle for maximal SHG efficiency in waveguides, a value dictated by QPM theory [fejer_quasi-phase-matched_1992]. The paper finds that, when using electrodes with elliptical geometry and optimized pulse sequences, the poling quality is minimally sensitive to duty cycle variations between 40% and 50%; significant effects are only observed when approaching a 60% electrode duty cycle.

Figure 1: Duty cycle variation (40%, 50%, 60%) of optimized elliptical poling electrodes and its impact on LiTaO3 domain inversion uniformity.

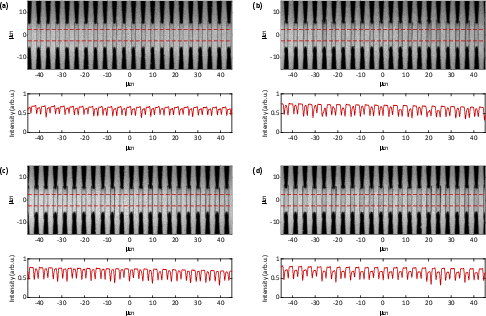

Poling Pulse Optimization

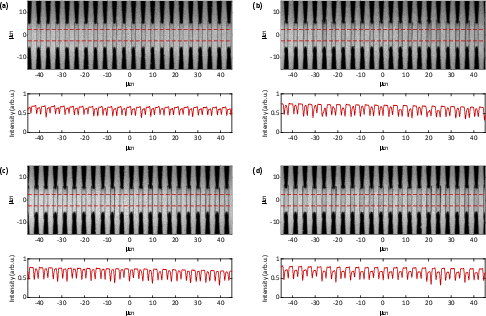

Analysis of poling pulse trains illustrates that domain inversion quality is robust against moderate changes in the number of applied pulses. Pulse trains comprising 10, 20, 30, or 40 pulses with controlled voltage profiles all achieve comparable uniformity, provided pulse timing and amplitude ensure the electric field exceeds the material’s coercive field [kim_coercive_2002]. This relaxes tight fabrication constraints and supports scalability.

Figure 2: Influence of pulse train length (10-40 pulses) on periodic domain inversion with fixed electrode geometry and 50% duty cycle.

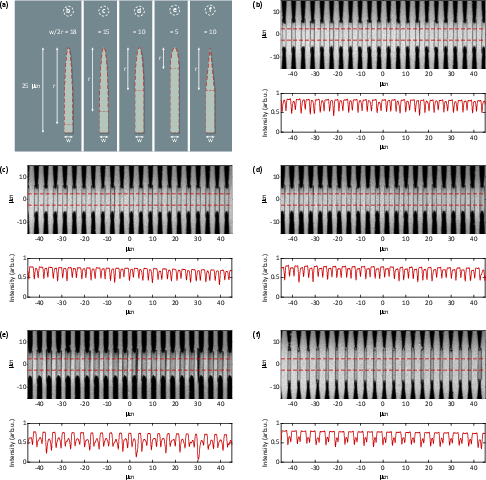

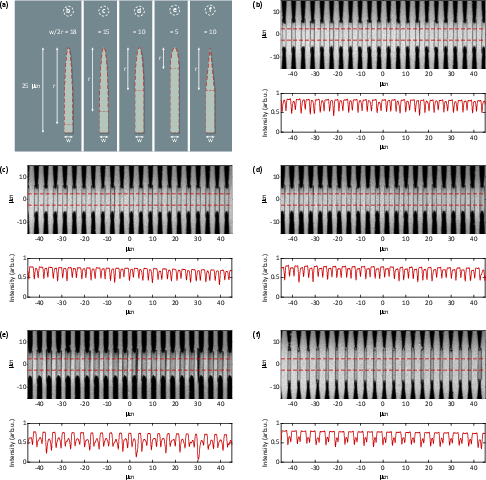

Electrode Shape Effects

The electrode tip shape critically impacts local electric field enhancement and domain nucleation. Elliptical electrode tips with high axis ratios (≥15) yield the most uniform domain inversion, balancing the trade-off between domain width and uniformity. Triangular tips also provide good quality but result in lower duty cycles, thus reducing SHG efficiency.

Figure 3: Comparative domain inversion with elliptical and triangular electrode tips, demonstrating optimal uniformity at elliptical axis ratios of 15 to 18.

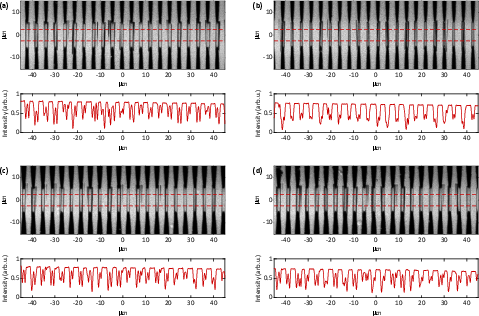

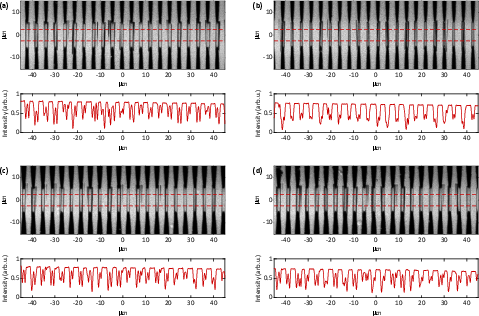

Single-Pulse Poling Limitations

Attempts to implement single-pulse poling—successful in LiNbO3—were not reproducible in thin-film LiTaO3. Single-pulse techniques yielded stochastic domain formation and low SHG efficiency, highlighting the need for multi-pulse trains and careful optimization of poling parameters for thin-film platforms.

Figure 4: Domain inversion under single 1.2 kV and 1.3 kV pulses, evidencing chaotic and non-uniform poling outcomes.

Electrode Spatial Arrangement and Cross-Talk

The paper identifies poling cross-talk as a critical limitation for device density on photonic chips. Regions with adjacent electrodes less than 120 μm apart exhibited unpredictable domain inversion due to charge accumulation and field overlap; increasing spacing to 160 μm mitigated this effect and enabled reproducible domain inversion. This spatial constraint must be considered in chip layout for integrated nonlinear photonics.

Figure 5: Cross-talk in poling regions for electrodes spaced by 40 μm versus 160 μm, with greater uniformity at larger separations.

Implications and Future Directions

The demonstrated watt-level SHG in thin-film PPLT extends the capabilities of ferroelectric integrated photonics for telecom, visible, and quantum networking applications [wang_lithium_2024; chen_continuous-wave_2025]. The systematic engineering of poling conditions, electrode design, and spatial arrangement establishes a process window for reproducible high-efficiency nonlinear devices compatible with wafer-scale manufacturing. PPLT provides lower birefringence, superior UV transparency, and high optical damage thresholds compared to LiNbO3, positioning it for scalable, high-power photonic integration [yan_high_2020; suntsov_optical_2024].

Anticipated developments include further reduction in fabrication variabilities, integration of additional functionalities (e.g., electro-optic modulation), and exploration of alternative metals or geometries for enhanced poling reliability. These advances will support the deployment of complex, high-density nonlinear photonic circuits for quantum and classical information processing.

Conclusion

The paper delineates key parameters governing high-power SHG in periodically poled thin-film lithium tantalate. By optimizing electrode geometry, pulse sequence, and device layout, it achieves the uniform domain inversion required for efficient QPM-based frequency conversion. The findings underpin the scaling of LiTaO3 integrated nonlinear photonics for volume manufacturing, offering a reproducible path to high-brightness SHG sources and functional photonic circuits. The work reaffirms the necessity of holistic optimization from material choice to microfabrication and chip-level architecture for next-generation photonic integration.