- The paper introduces a system that uses hierarchical discrete lattice blocks and modular robots to reduce assembly steps, as shown by a 4x4x4 voxel block needing only four placements.

- It employs a novel methodology integrating voxelization, hierarchical pattern recognition, and a real-time digital twin for optimized robotic assembly and error correction.

- Key results demonstrate high throughput (up to 4,394,000 mm³/min per robot) and cost-effectiveness, paving the way for advanced architectural and infrastructural applications.

Hierarchical Discrete Lattice Assembly for Scalable Macroscale Digital Fabrication

Introduction and Motivation

The paper presents a comprehensive system for the scalable digital fabrication of meter-scale structures using hierarchical discrete lattice blocks and modular mobile robots. The central challenge addressed is the limitation of conventional digital fabrication systems, which are typically constrained by the size of the fabrication machine itself. The proposed approach leverages architected lattice blocks, produced via desktop-scale digital fabrication, and assembles them into large structures using simple, mobile robots. This system is designed to optimize assembly throughput, mechanical stability, and scalability, while minimizing hardware complexity and cost.

System Architecture and Lattice Design

The core material system is based on edge-connected octet lattice blocks, which are compounded into larger, self-aligning, interlocking units. These blocks are fabricated using FFF 3D printing in PLA, with printability features such as flanges to support overhangs and snap-fit connectors for vertical assembly. The compounded blocks vary in size and orientation, allowing for hierarchical assembly and optimization of geometric fidelity versus assembly speed.

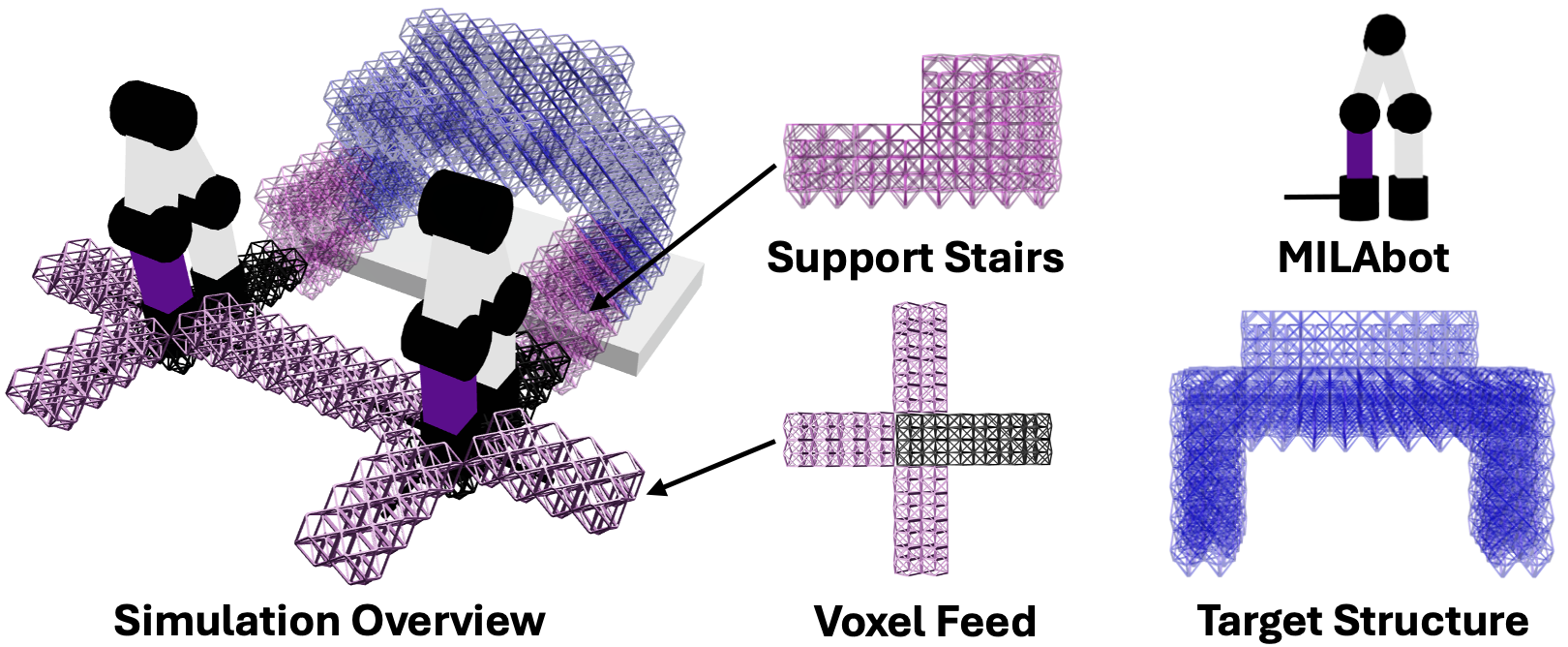

Figure 1: Overview of the edge-connected octet lattice and its decomposition into compounded arrangements for robotic assembly.

The self-aligning features of the lattice blocks permit significant placement error correction, enabling robots to perform coarse placement followed by mechanical engagement via snap-fit connections. This design reduces the requirements for high-precision robotic manipulation and facilitates robust, scalable assembly.

Software Pipeline: Voxelization, Sequencing, and Path Planning

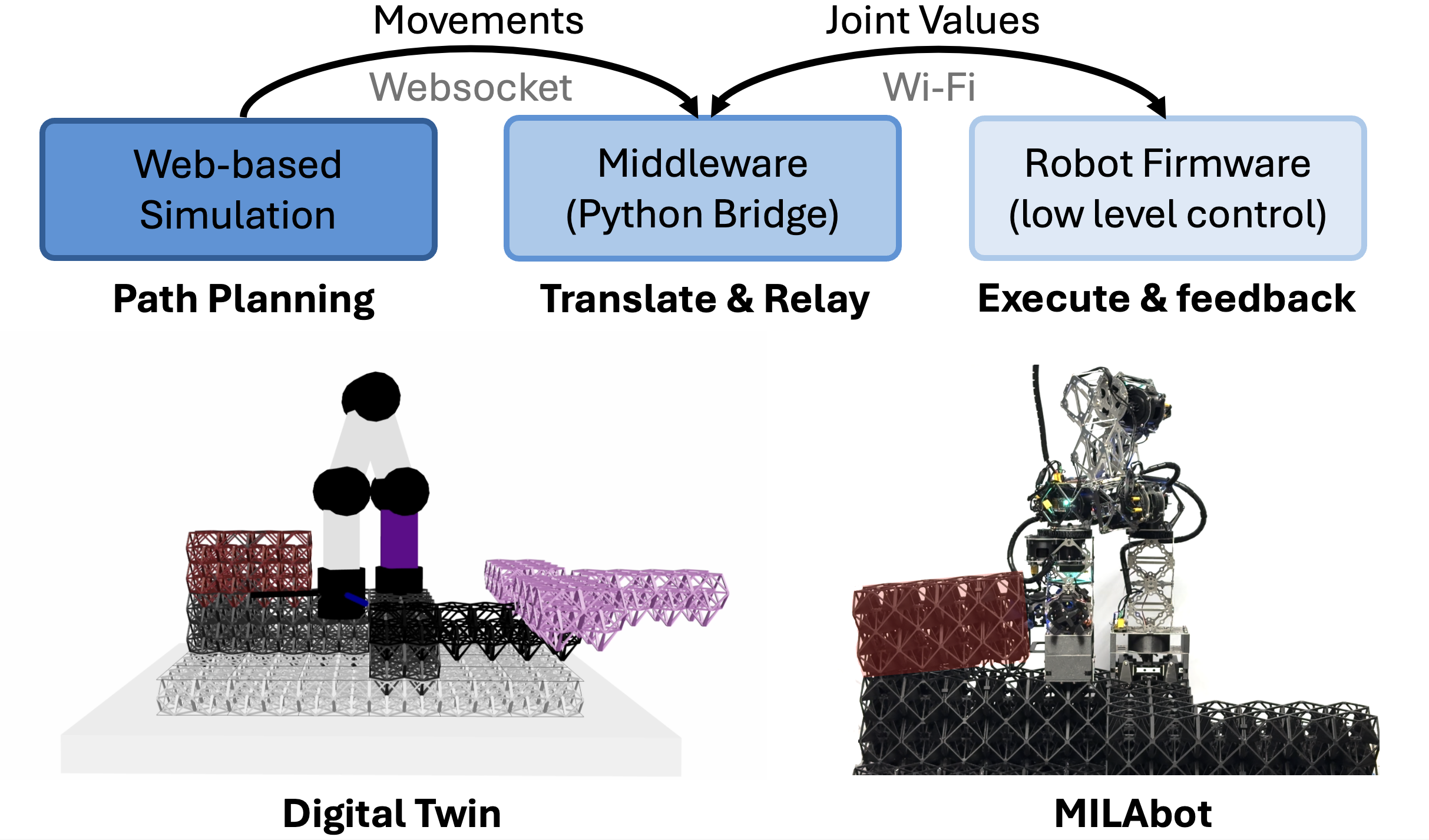

A web-based software environment, implemented in JavaScript with Three.js, orchestrates the entire assembly pipeline. The process begins with voxelization of STL meshes at a 65mm resolution, followed by hierarchical pattern recognition to group voxels into larger blocks. The system prioritizes larger patterns to maximize assembly efficiency and fills gaps with smaller units as needed.

Figure 2: Tiling of compounded voxel blocks and interconnection through staggered layers for structural stability.

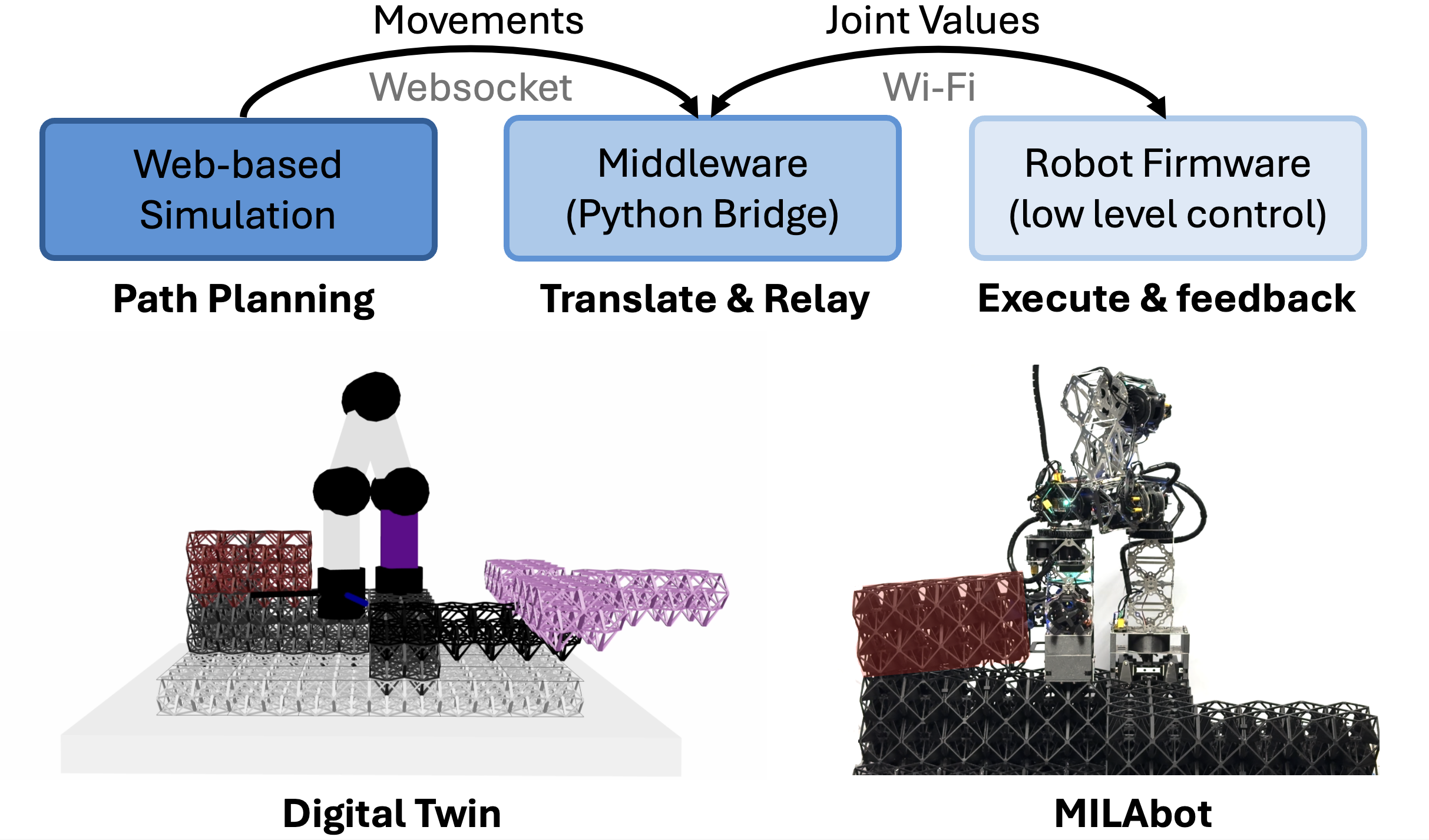

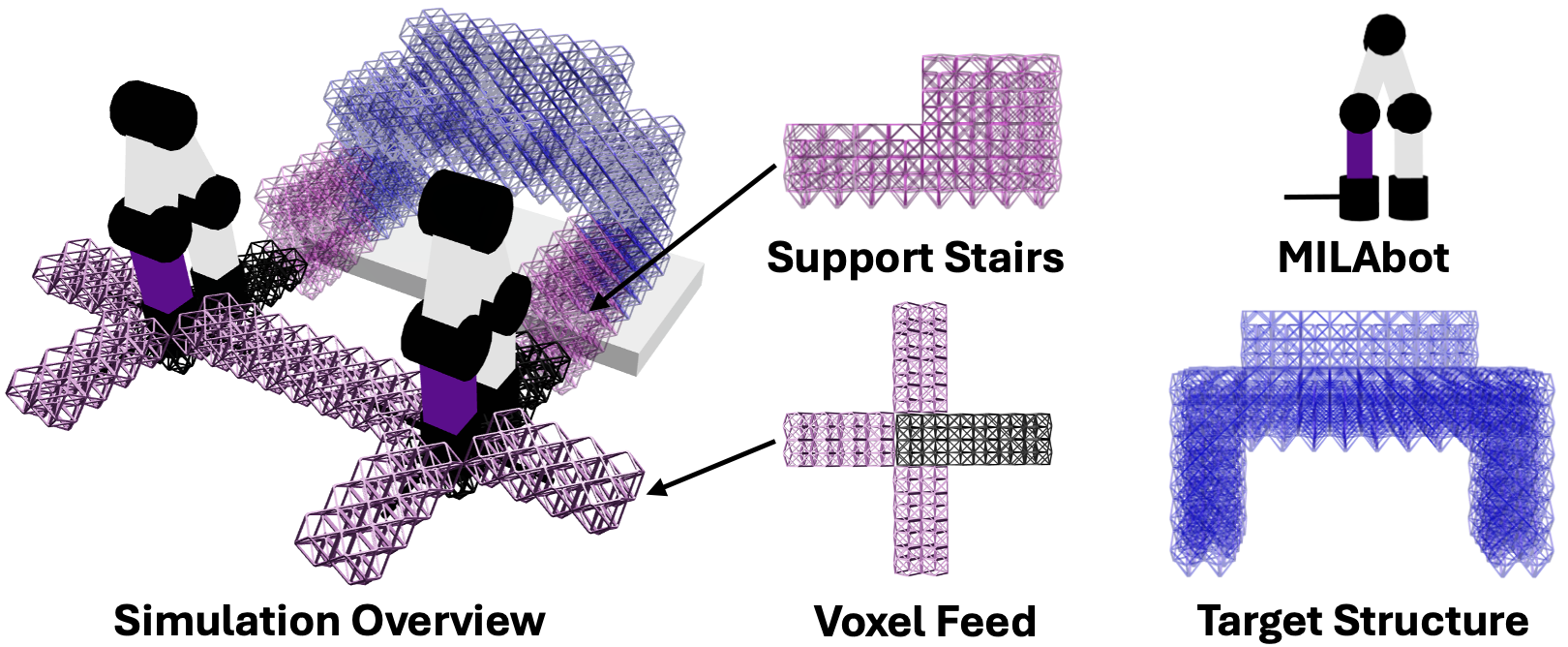

The build sequence is determined by partitioning the structure among robots based on proximity to voxel feed locations, ensuring balanced workload distribution. The assembly proceeds layer-by-layer, with each robot autonomously navigating the structure using an A* algorithm adapted to the discrete voxel grid. The digital twin simulation environment provides real-time feedback and control, synchronizing the virtual and physical robots via WebSocket communication.

Figure 3: Simulation overview with MILAbot, support stairs, voxel feed, and target structure.

Figure 4: Data flow from web-based simulation to MILAbot and digital twin synchronization with physical execution.

Hardware Implementation: Modular Inchworm Lattice Assembler (MILAbot)

The MILAbot is a modular inchworm-style robot designed for hierarchical assembly and eventual self-replication. It consists of actuated joints, passive spacers, gripper feet, and voxel carriers, arranged in a configuration analogous to a five-DOF arm. Each module is networked via I2C, with a WiFi-enabled microcontroller for coordination.

Figure 5: MILAbot with labeled modules: actuated joints, passive spacers, gripper feet, and voxel carriers.

The actuator modules utilize BLDC motors with two-stage reduction and magnetic encoders for feedback. Gripper feet are designed for robust attachment to the lattice, while voxel carriers enable the transport of multiple blocks per trip. The robot's mechanical compliance and alignment features allow for reliable operation with minimal sensing and control overhead.

Figure 6: Motor module design with BLDC motor, reduction stages, and PCB attachment plates.

Figure 7: Operation of structure gripper and voxel payload gripper in MILAbot.

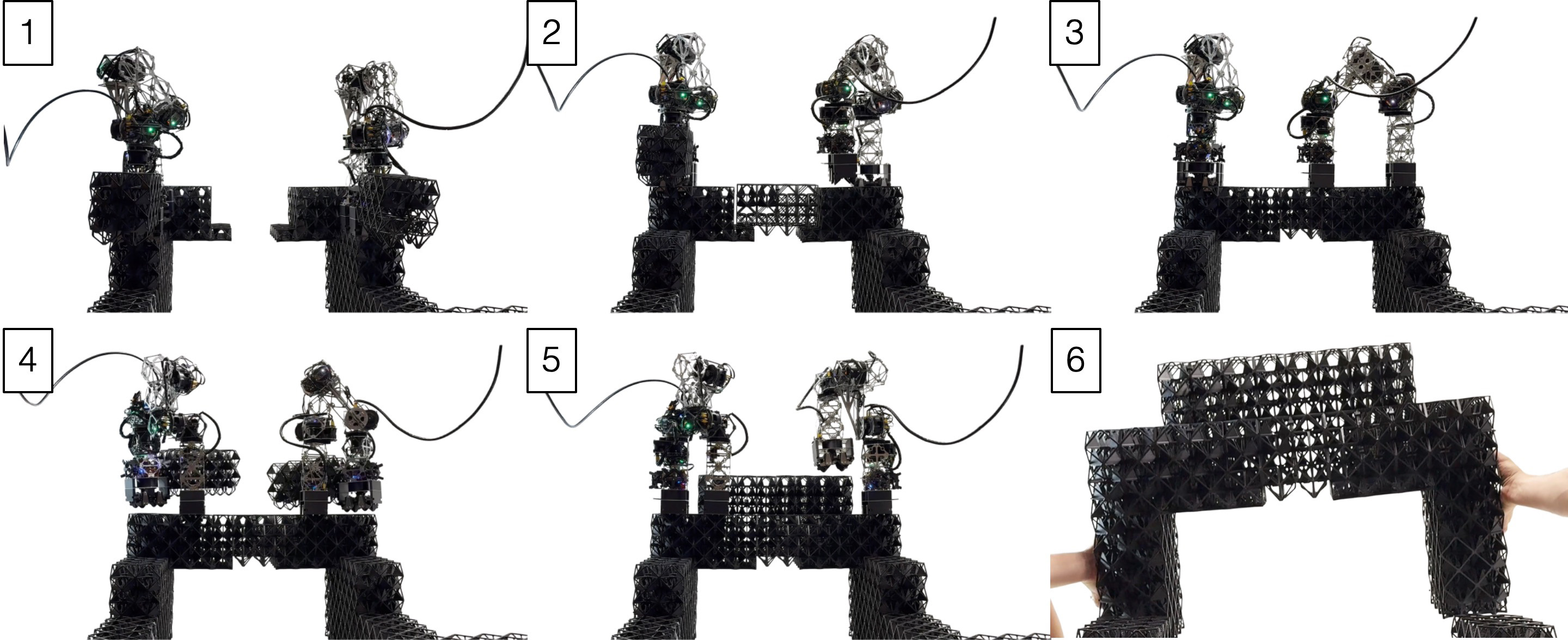

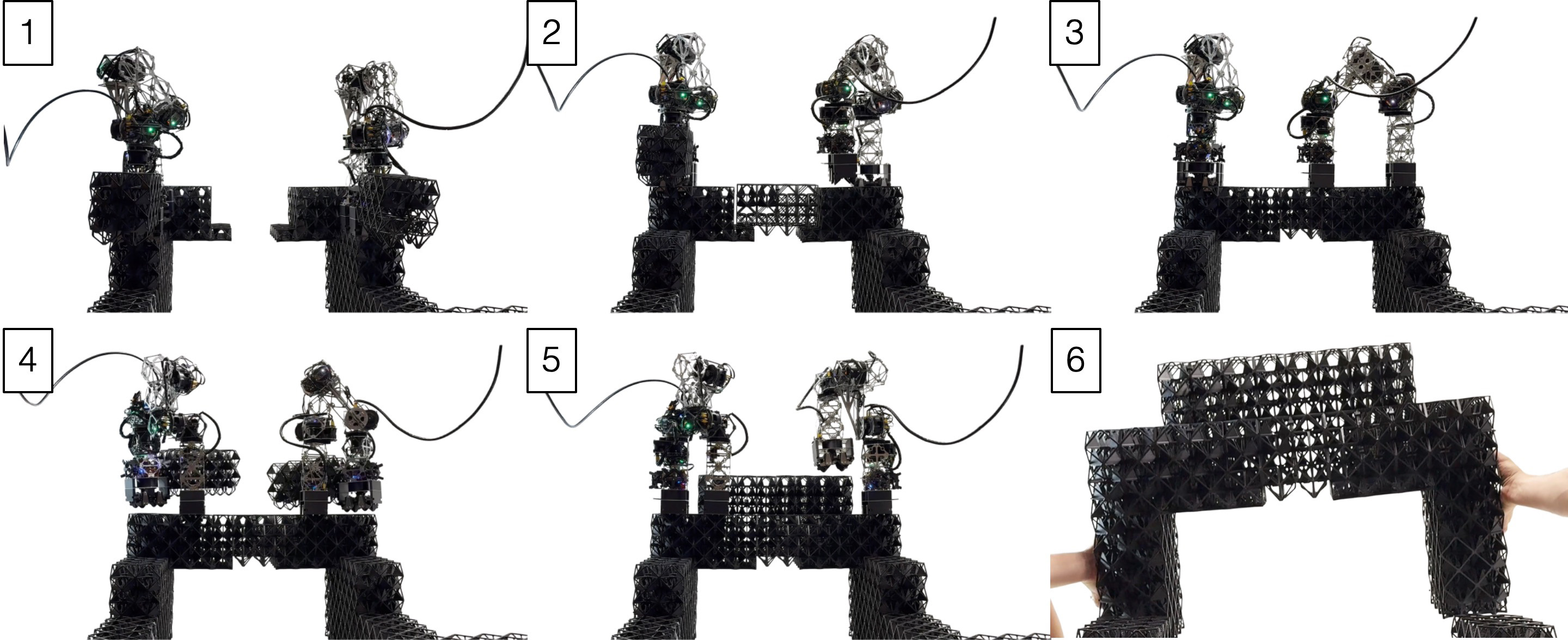

The system is validated through the robotic assembly of meter-scale structures, including cubes, staircases, and benches. Hierarchical blocking enables dramatic reductions in the number of placements required; for example, a 4x4x4 voxel block is assembled with only four placements using compounded blocks, compared to 64 placements with single voxels.

Figure 8: Assembly of a 4x4x4 voxel block using compounded blocks, carried two at a time.

Figure 9: Single robot assembling a support staircase for the bench build.

Figure 10: Two robots collaborating to assemble a bench.

Figure 11: Assembled bench supporting two people, demonstrating load-bearing capability.

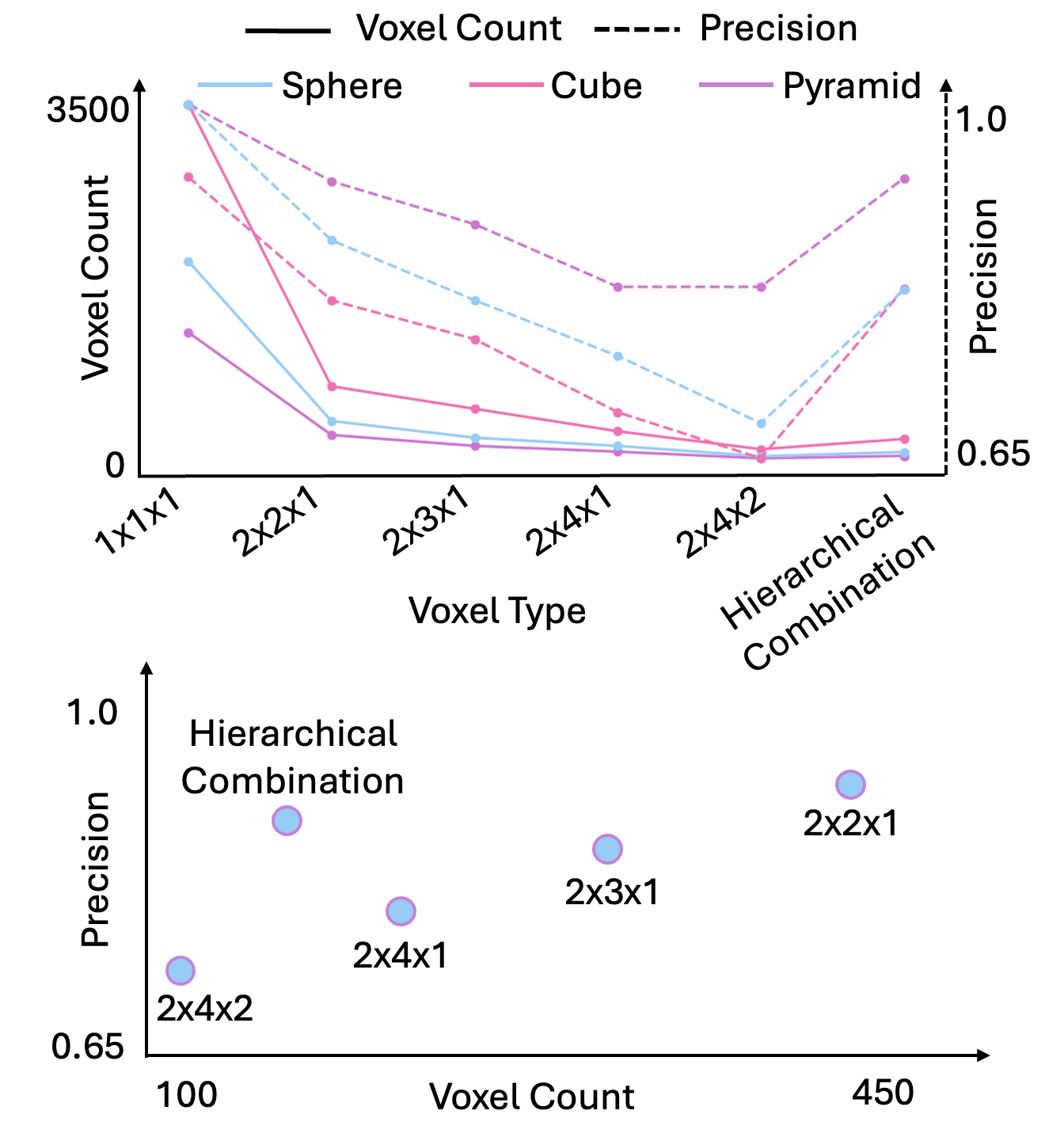

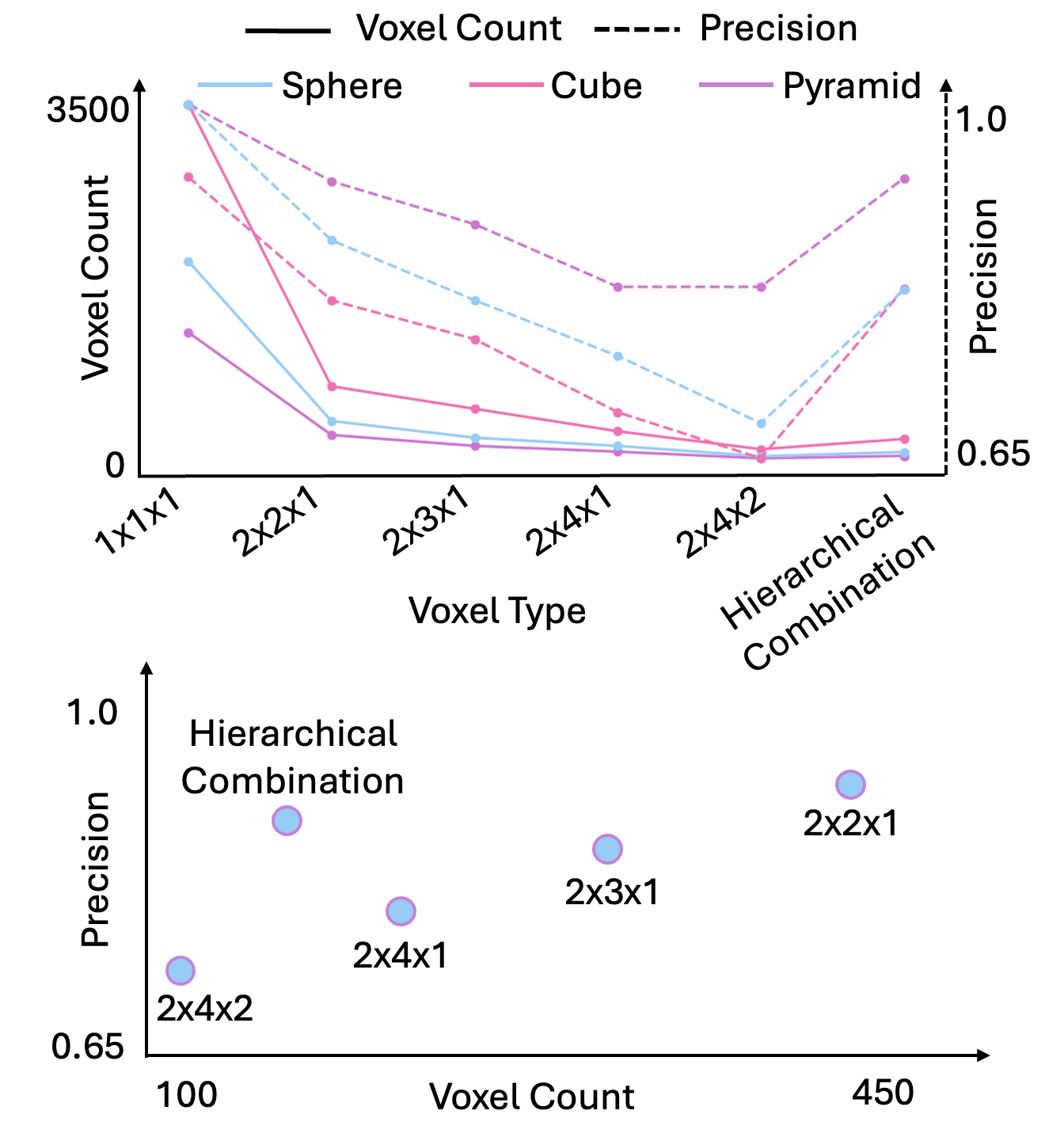

Quantitative analysis of voxelization strategies reveals that hierarchical combinations of block types break the linear trade-off between voxel size and geometric precision, achieving high fidelity with reduced element count.

Figure 12: Hierarchical combination of voxel patterns outperforms single types in precision versus voxel count.

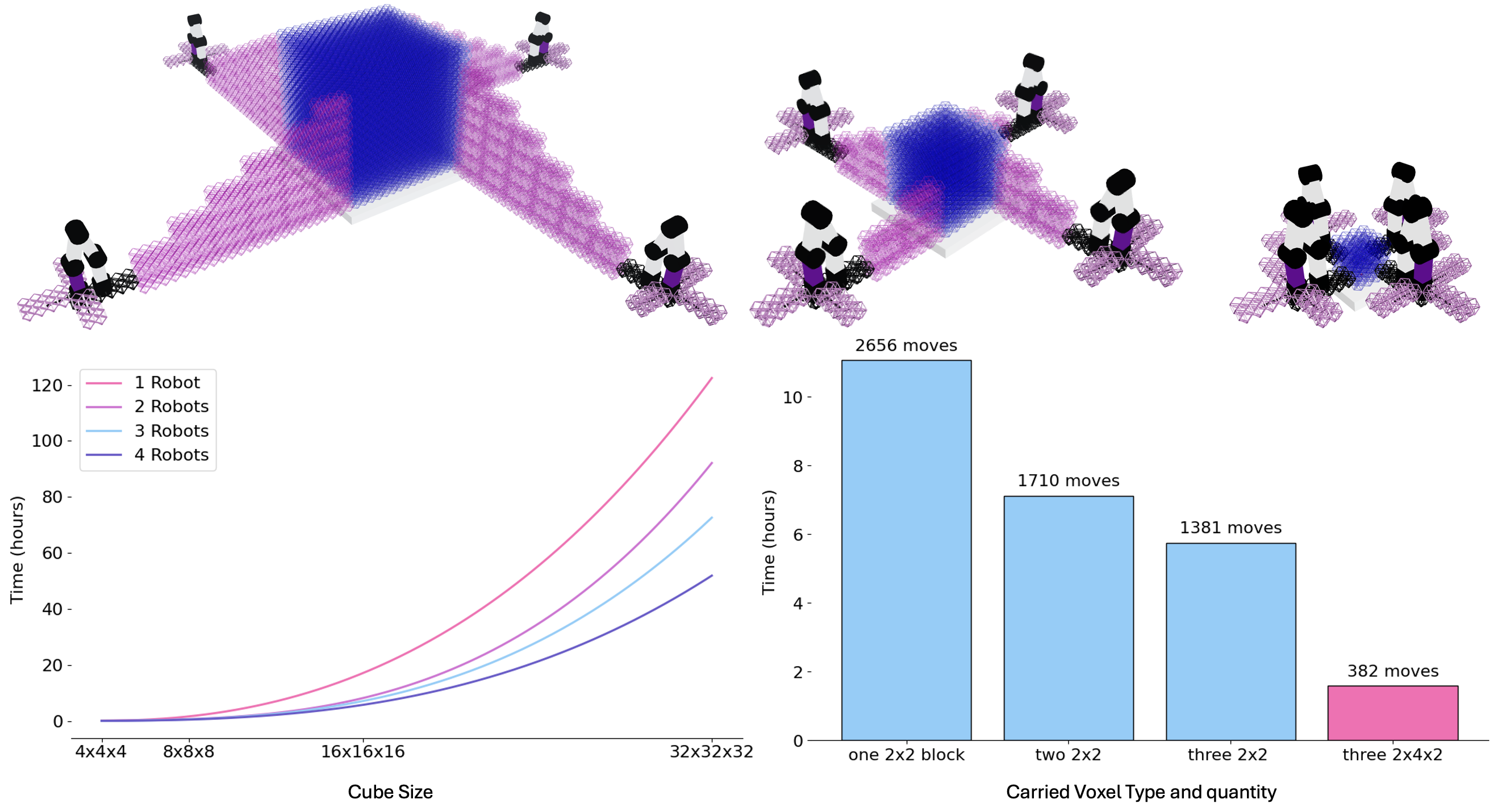

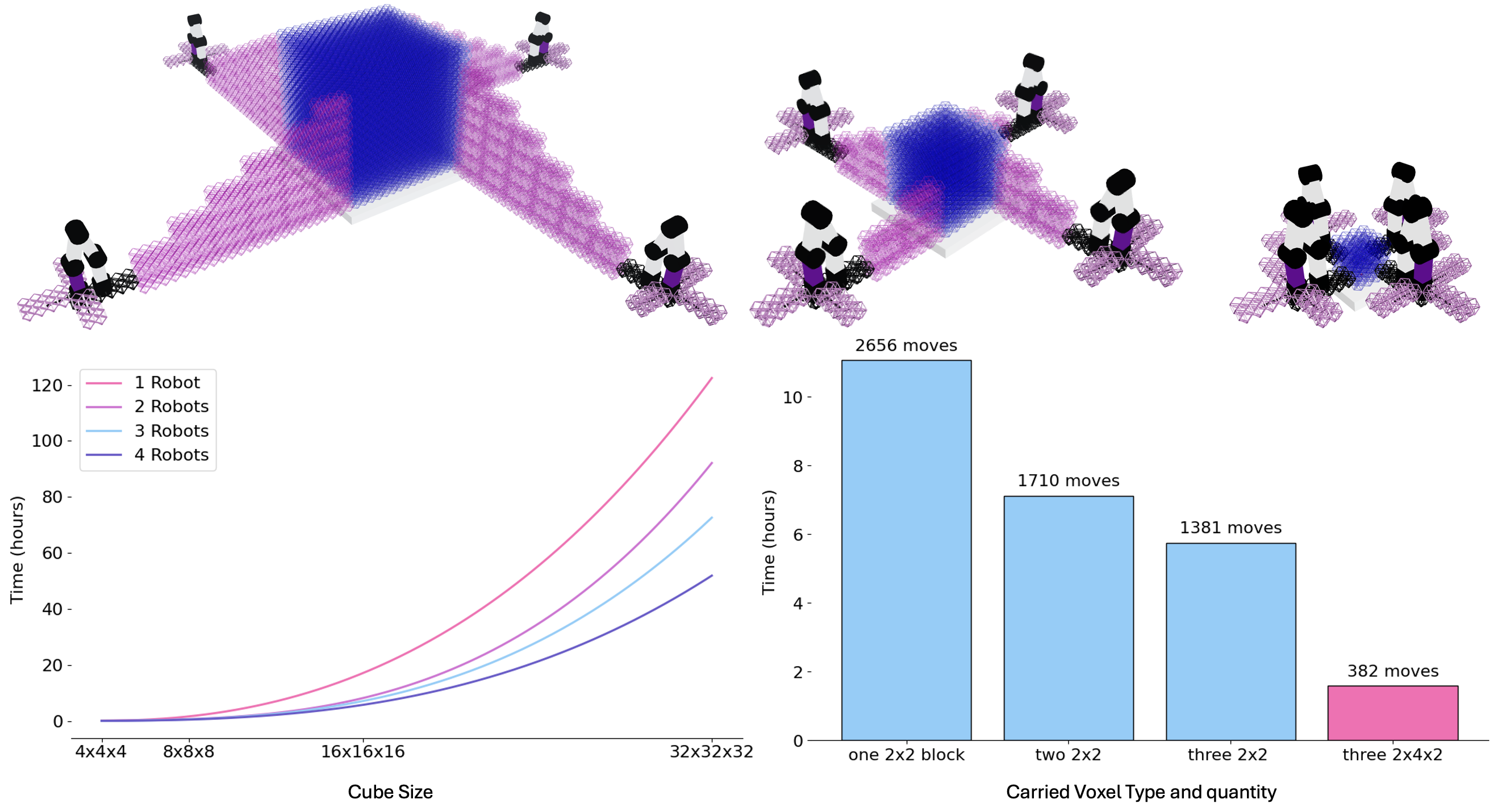

Simulation studies show that increasing the number of robots and optimizing carrying strategies (e.g., transporting larger compound blocks) substantially decreases build time, with diminishing returns due to independent support stair construction.

Figure 13: Impact of robot quantity and voxel carrying strategy on build time for large structures.

Mechanical and Economic Efficiency

Mechanical testing demonstrates that the compounded octet lattice blocks achieve stretch-dominated behavior, with relative compressive modulus scaling linearly with relative density, outperforming prior robotically assembled discrete lattices. The system supports high loads relative to its own weight, with a 2x2x2 block sustaining 3445N (2220x its own weight).

Figure 14: Relative compressive modulus and density comparison for robotically assembled discrete lattices.

Volumetric assembly throughput is highest among compared systems (4,394,000 mm³/min for a single robot carrying two 4x2x2 blocks), at the second lowest system cost, indicating efficient scaling via hierarchical material handling.

Figure 15: Volumetric throughput versus system cost for different voxel assembly systems.

Limitations and Future Directions

The current voxelization algorithm is sensitive to input geometry and lacks generalizability. Future work will explore octree-based and learning-based methods for robust, structure-aware voxelization. Feeder management is currently static; dynamic allocation and shared sourcing strategies are needed for improved scalability. Robot control will require per-unit calibration and advanced IK models as the system scales. Material anisotropy in FFF-printed PLA limits practical applications; future iterations will investigate mass-manufacturable, high-performance materials and electrically active voxels.

Figure 16: Comparison of infeasible and feasible structures due to local connectivity constraints.

Conclusion

This work establishes a scalable, cost-effective pipeline for the digital fabrication of large structures via hierarchical discrete lattice assembly and modular mobile robots. The integration of architected lattice blocks, hierarchical voxelization, and real-time digital twin simulation enables efficient, parallelized construction with robust mechanical performance. The demonstrated system provides a foundation for future research in multi-robot collaboration, recursive assembly, and the co-design of material-robot systems for architectural, infrastructural, and extraterrestrial applications.