ByteWrist: A Parallel Robotic Wrist Enabling Flexible and Anthropomorphic Motion for Confined Spaces (2509.18084v2)

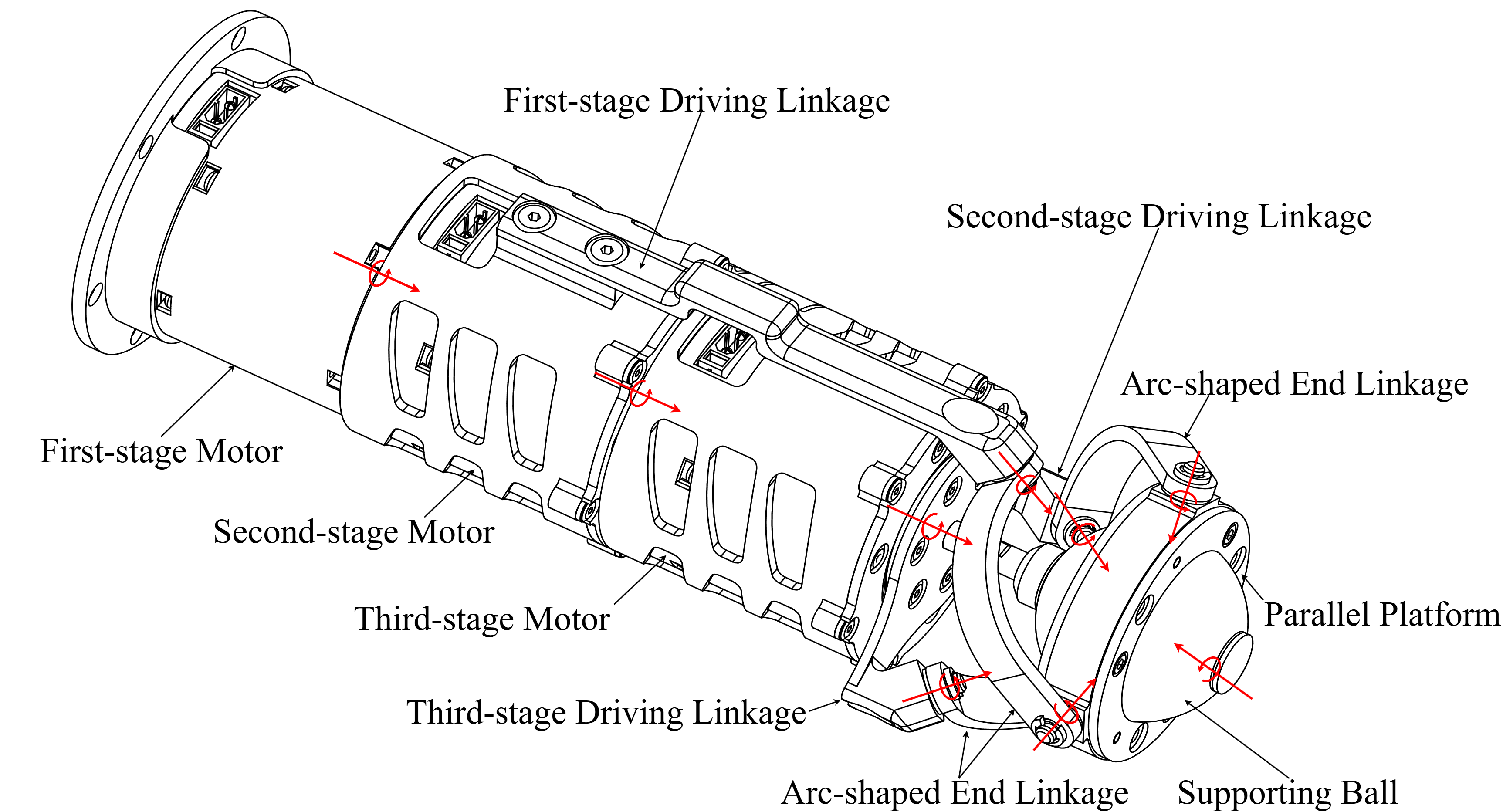

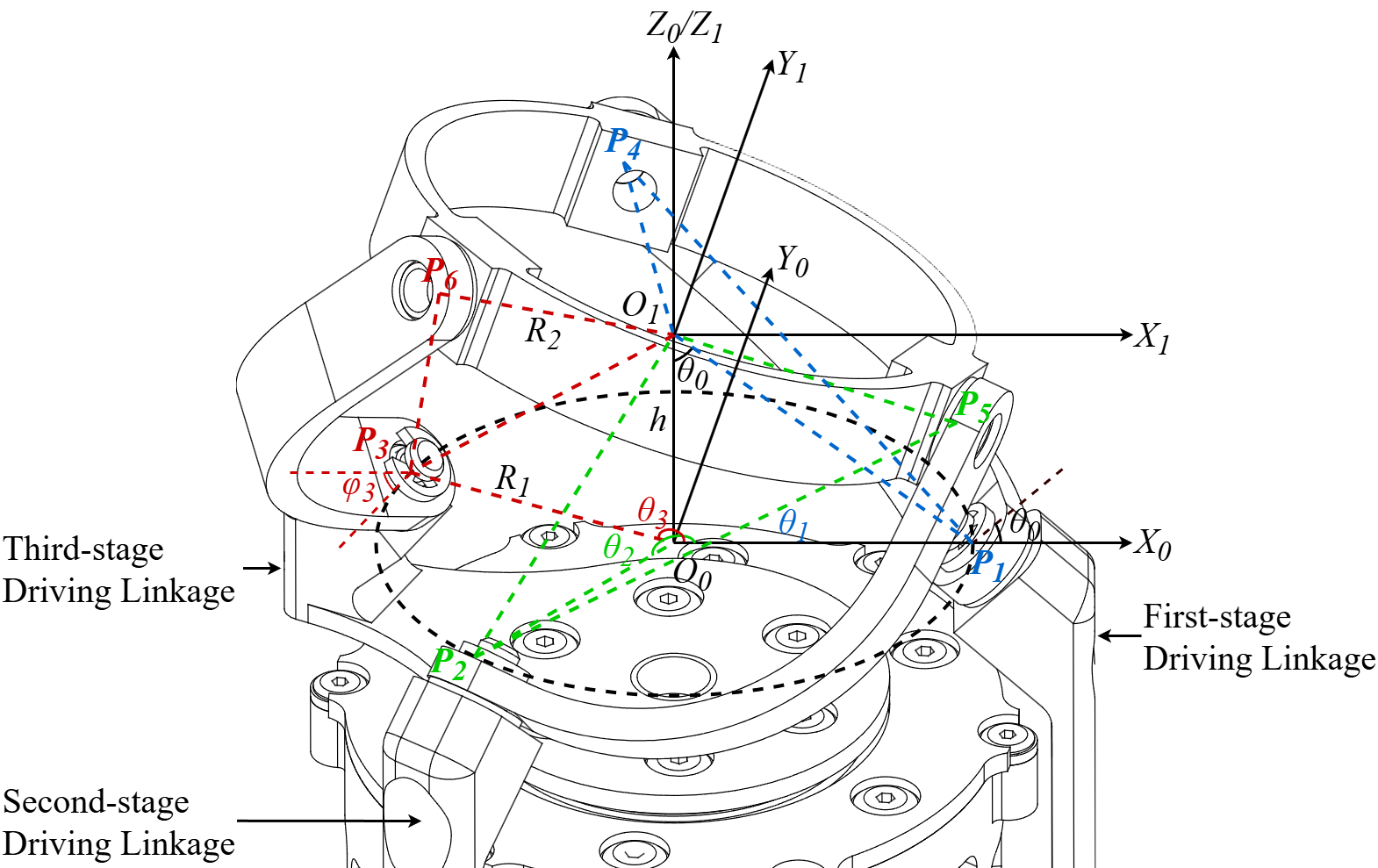

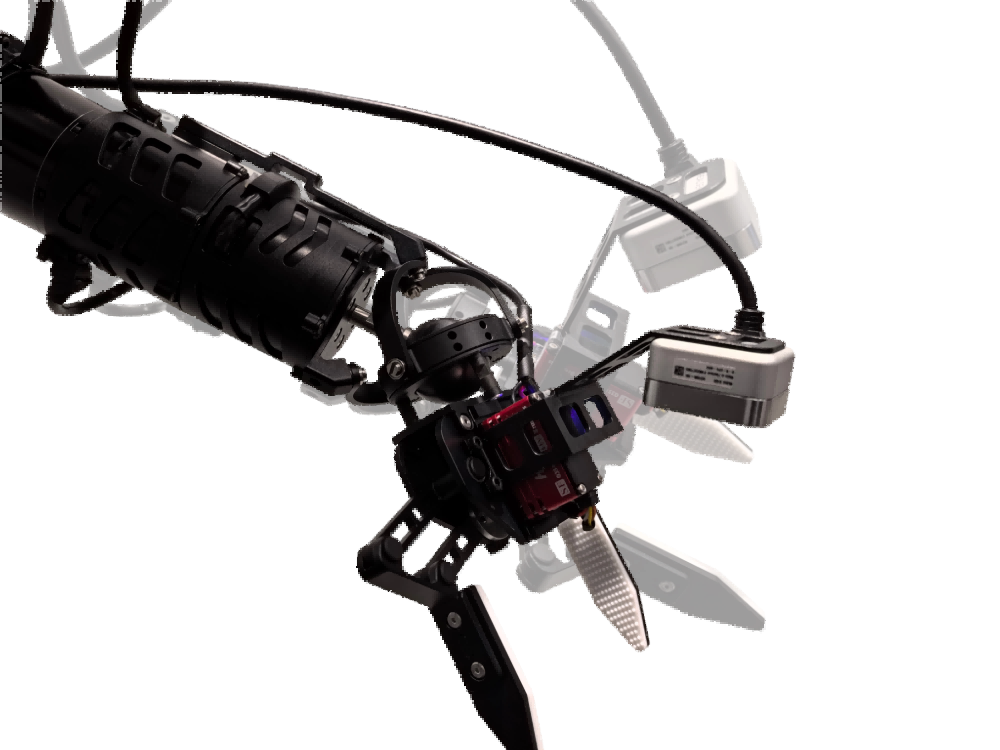

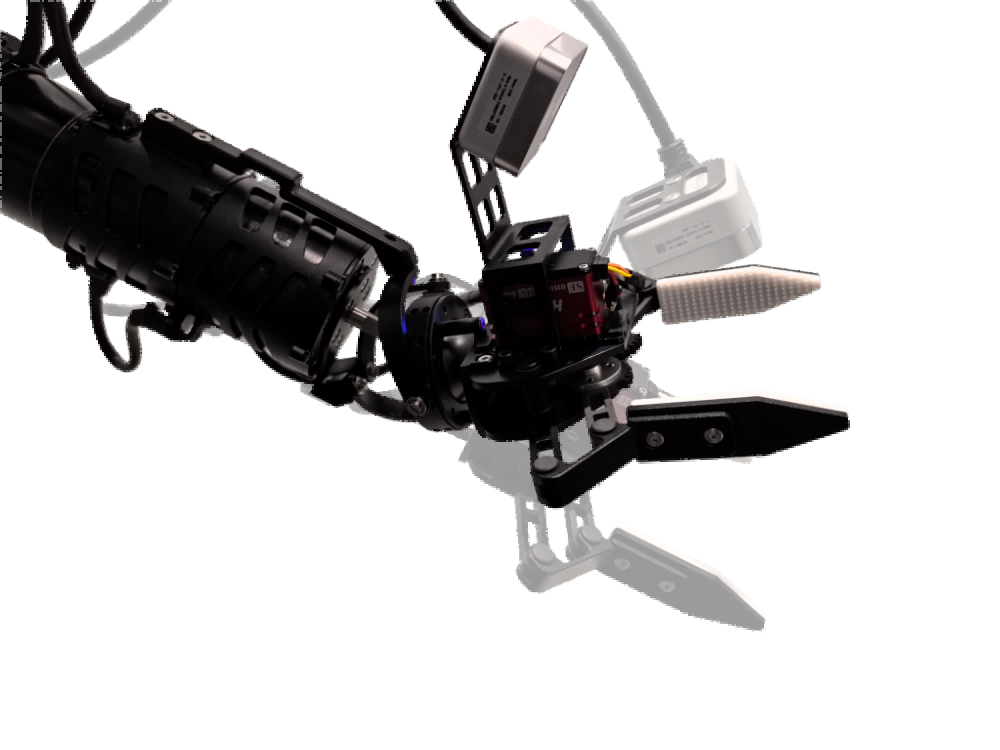

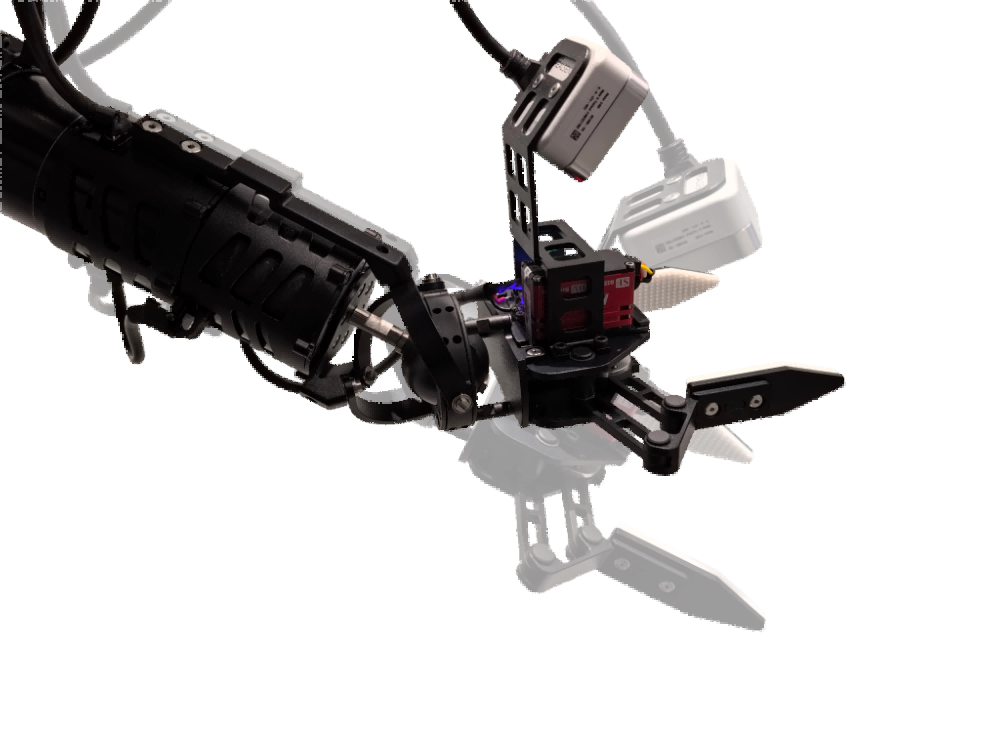

Abstract: This paper introduces ByteWrist, a novel highly-flexible and anthropomorphic parallel wrist for robotic manipulation. ByteWrist addresses the critical limitations of existing serial and parallel wrists in narrow-space operations through a compact three-stage parallel drive mechanism integrated with arc-shaped end linkages. The design achieves precise RPY (Roll-Pitch-Yaw) motion while maintaining exceptional compactness, making it particularly suitable for complex unstructured environments such as home services, medical assistance, and precision assembly. The key innovations include: (1) a nested three-stage motor-driven linkages that minimize volume while enabling independent multi-DOF control, (2) arc-shaped end linkages that optimize force transmission and expand motion range, and (3) a central supporting ball functioning as a spherical joint that enhances structural stiffness without compromising flexibility. Meanwhile, we present comprehensive kinematic modeling including forward / inverse kinematics and a numerical Jacobian solution for precise control. Empirically, we observe ByteWrist demonstrates strong performance in narrow-space maneuverability and dual-arm cooperative manipulation tasks, outperforming Kinova-based systems. Results indicate significant improvements in compactness, efficiency, and stiffness compared to traditional designs, establishing ByteWrist as a promising solution for next-generation robotic manipulation in constrained environments.

Paper Prompts

Sign up for free to create and run prompts on this paper using GPT-5.

Top Community Prompts

Explain it Like I'm 14

What is this paper about?

This paper introduces ByteWrist, a new kind of robot “wrist” that is small, strong, and can move in a very human-like way. It’s designed to work well in tight spaces like cabinets, medical areas, and crowded machines. Instead of stacking joints one after another (a “serial” wrist), ByteWrist uses a “parallel” design where three small drives work together at the same time. This makes it compact, accurate, and stiff (not wobbly), which is great for precise tasks.

What questions did the researchers ask?

- Can we build a robot wrist that is both compact and very flexible, so it works well in tight spaces?

- Can it be strong and precise while still moving smoothly like a human wrist?

- Can we model and control its movements accurately (so it goes exactly where we tell it to)?

- Does it actually outperform a popular serial-wrist robot when real tasks are done in cramped places?

How did they build and control ByteWrist?

The design in simple terms

Think of a camera gimbal that can roll, pitch, and yaw (turn about three axes). ByteWrist does the same three movements: roll, pitch, and yaw (often called RPY).

Key ideas:

- Three nested motors: Imagine three small motors tucked inside each other like Russian nesting dolls. Each one moves a “linkage” (like a short arm) that helps tilt/turn the platform at the end.

- Arc-shaped end linkages: These are curved pieces that transmit force smoothly and allow larger angles without taking up much space—like sliding along a curved track.

- A central supporting ball: This acts like a tiny ball joint in the middle. It helps the wrist stay stiff and stable while still being flexible.

- All the hinge axes point toward the center: That geometry helps keep the motion precise and compact.

Compared to a serial wrist (joints stacked end to end), a parallel wrist shares the work across multiple branches at once—kind of like three friends holding and tilting a tray together. That makes it more stable and accurate.

The math, explained simply

To control a wrist like this, you need to translate between:

- Motor angles → the platform’s roll, pitch, yaw (this is “forward kinematics”).

- Desired roll, pitch, yaw → motor angles (this is “inverse kinematics”).

Because the geometry is tricky, they use:

- A “guess-and-improve” method (Newton–Raphson) to solve the forward problem. Think of it like narrowing down a number by trying, checking, and adjusting quickly.

- A rotation matrix for roll, pitch, yaw to describe the exact orientation in space.

- A Jacobian matrix to see how small changes in the motor angles affect small changes in roll, pitch, and yaw. They compute this numerically (by nudging one motor a tiny bit and measuring the effect). They found a tiny step of 0.001 radians works best for accuracy.

What experiments did they run?

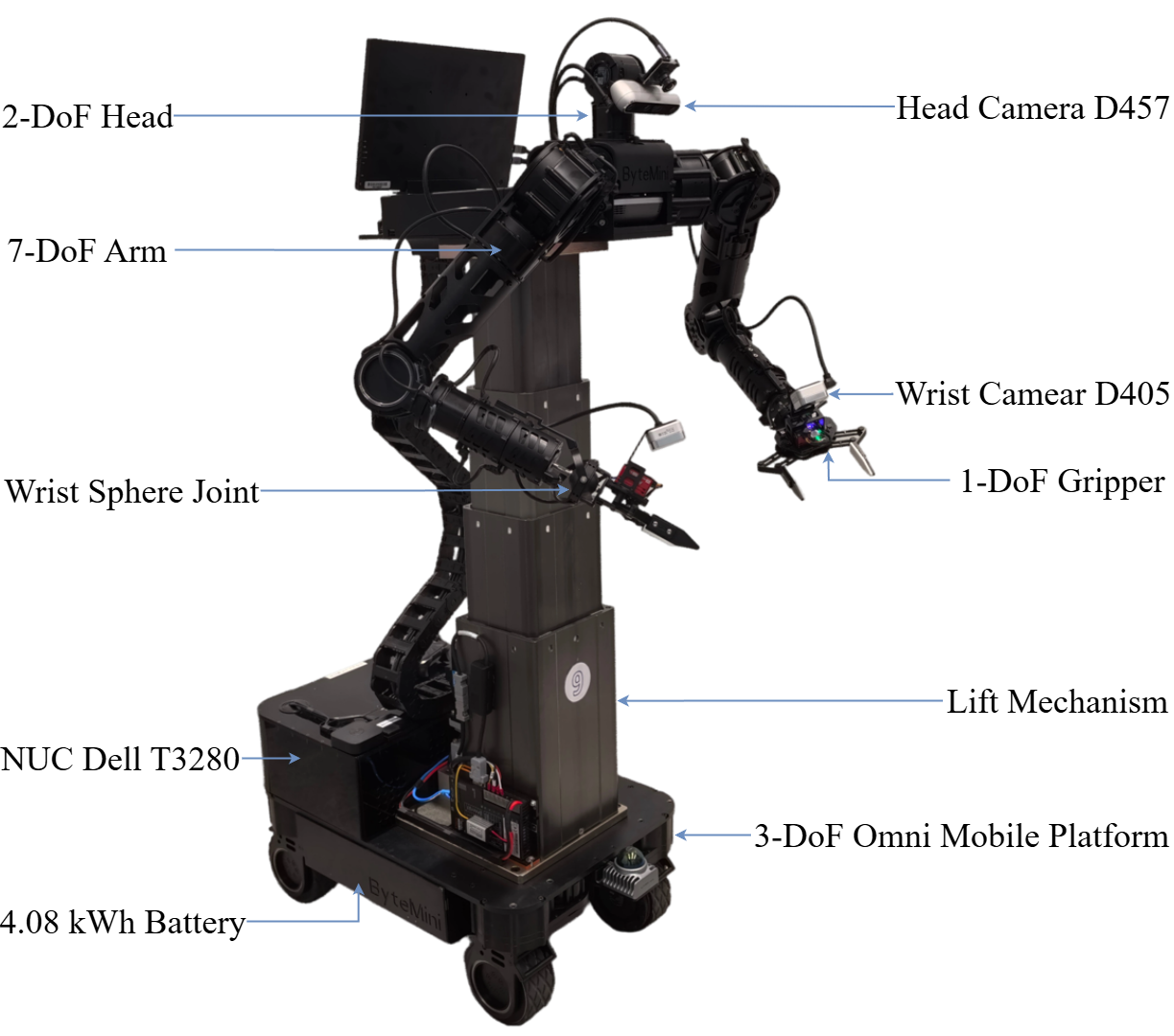

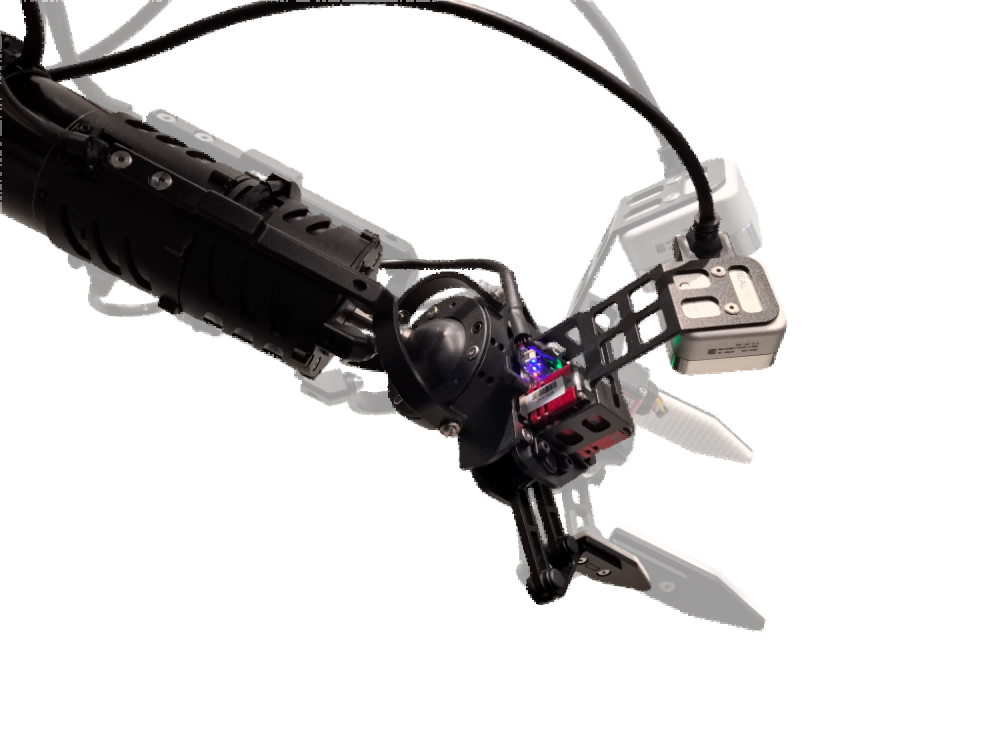

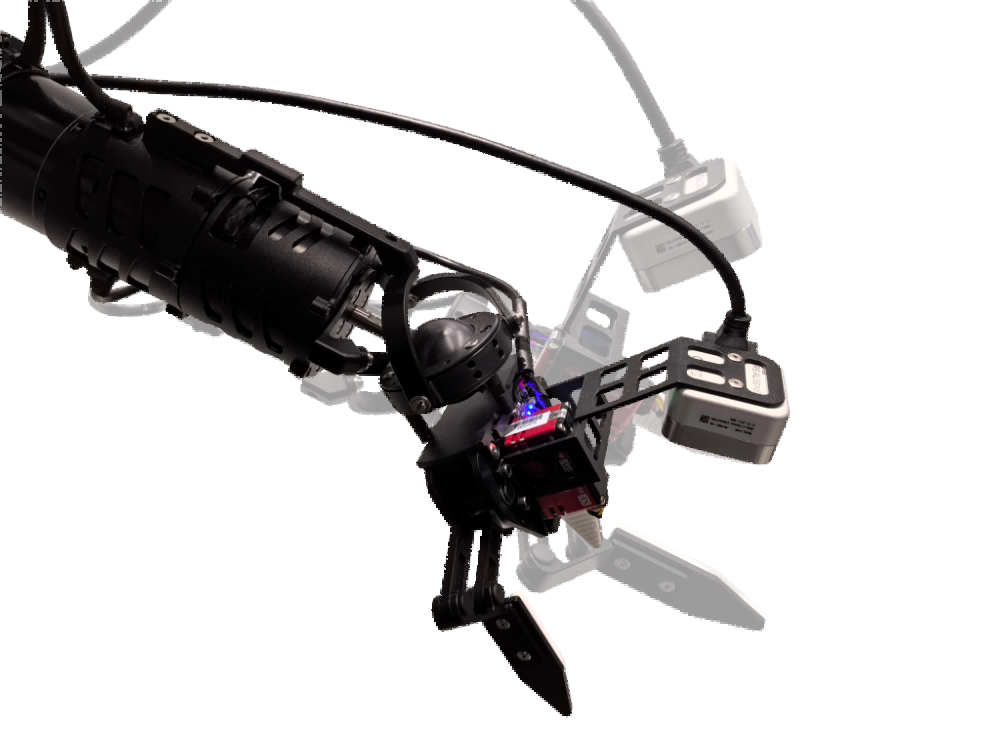

They built a full dual-arm mobile robot called ByteMini and tested ByteWrist in three ways:

1) Motion range test

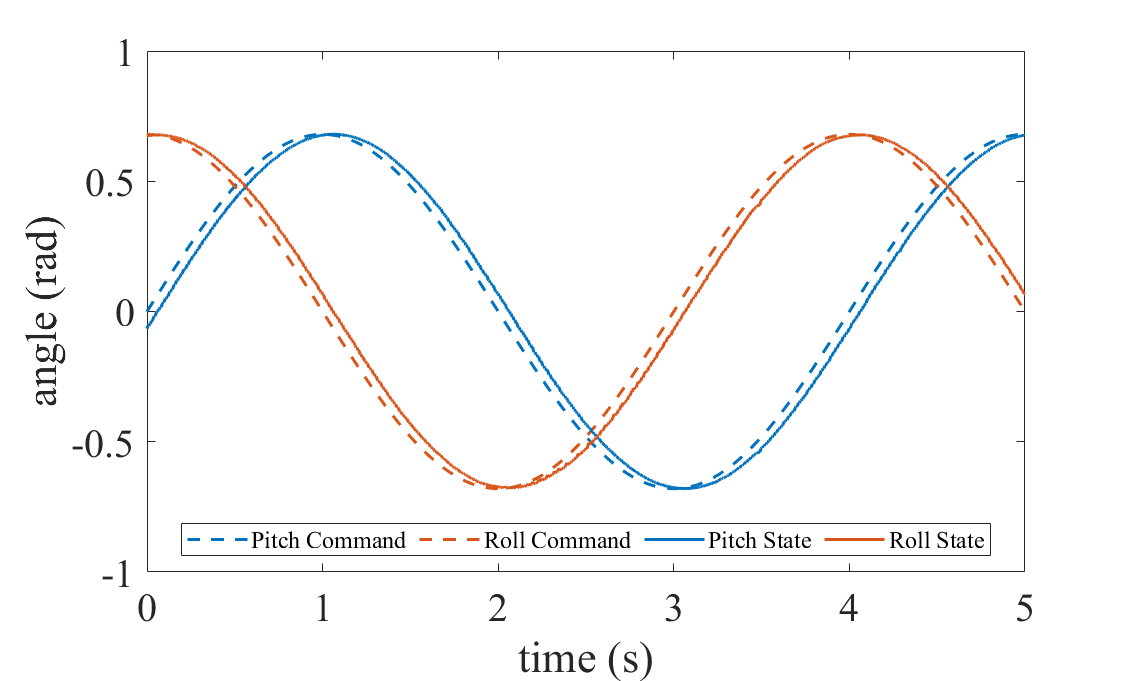

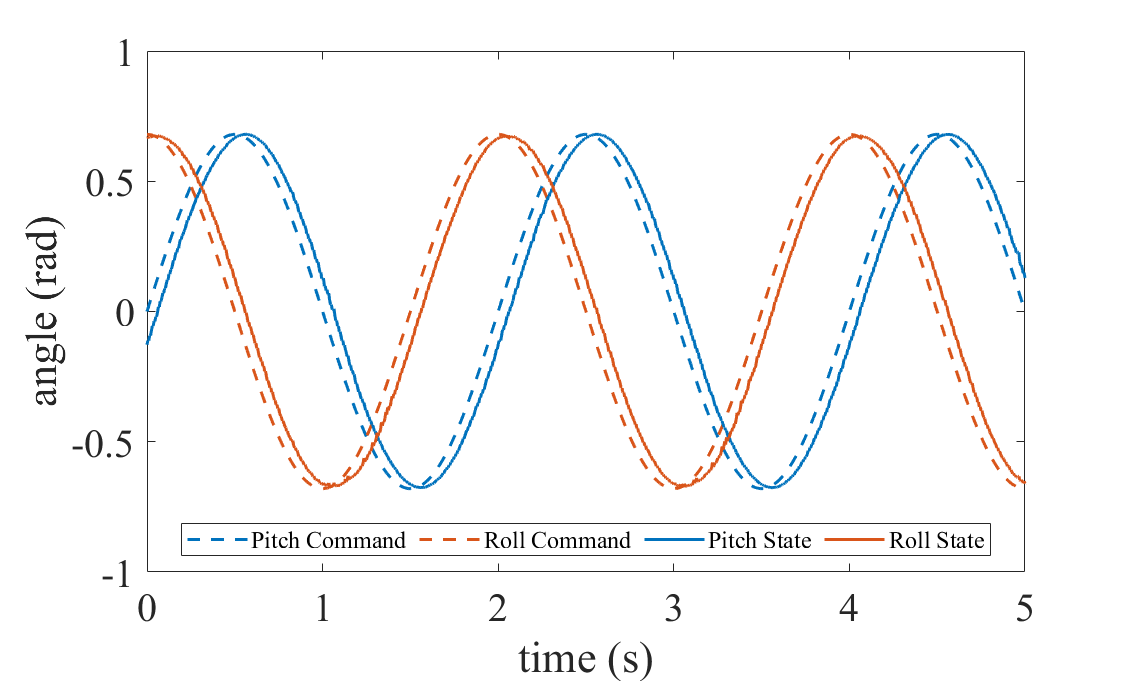

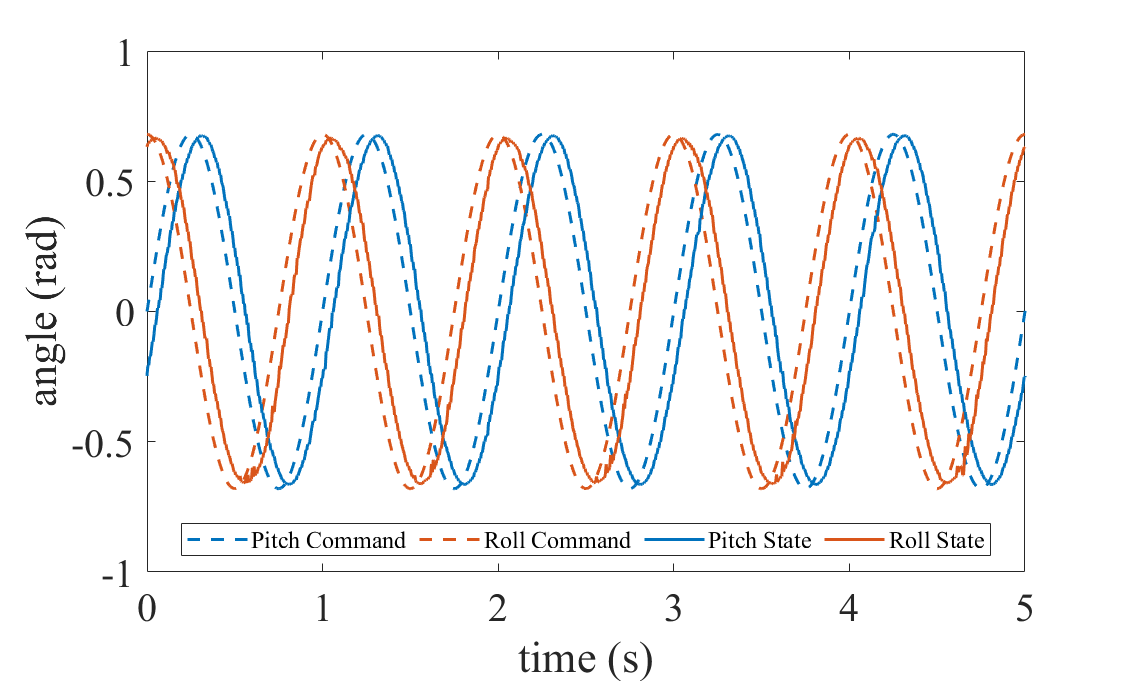

- They moved the wrist along a circular path in roll–pitch space at different speeds.

- It followed commands smoothly. At high speed there was about a 0.06-second control delay, which caused bigger errors; at lower speed the tracking was tight.

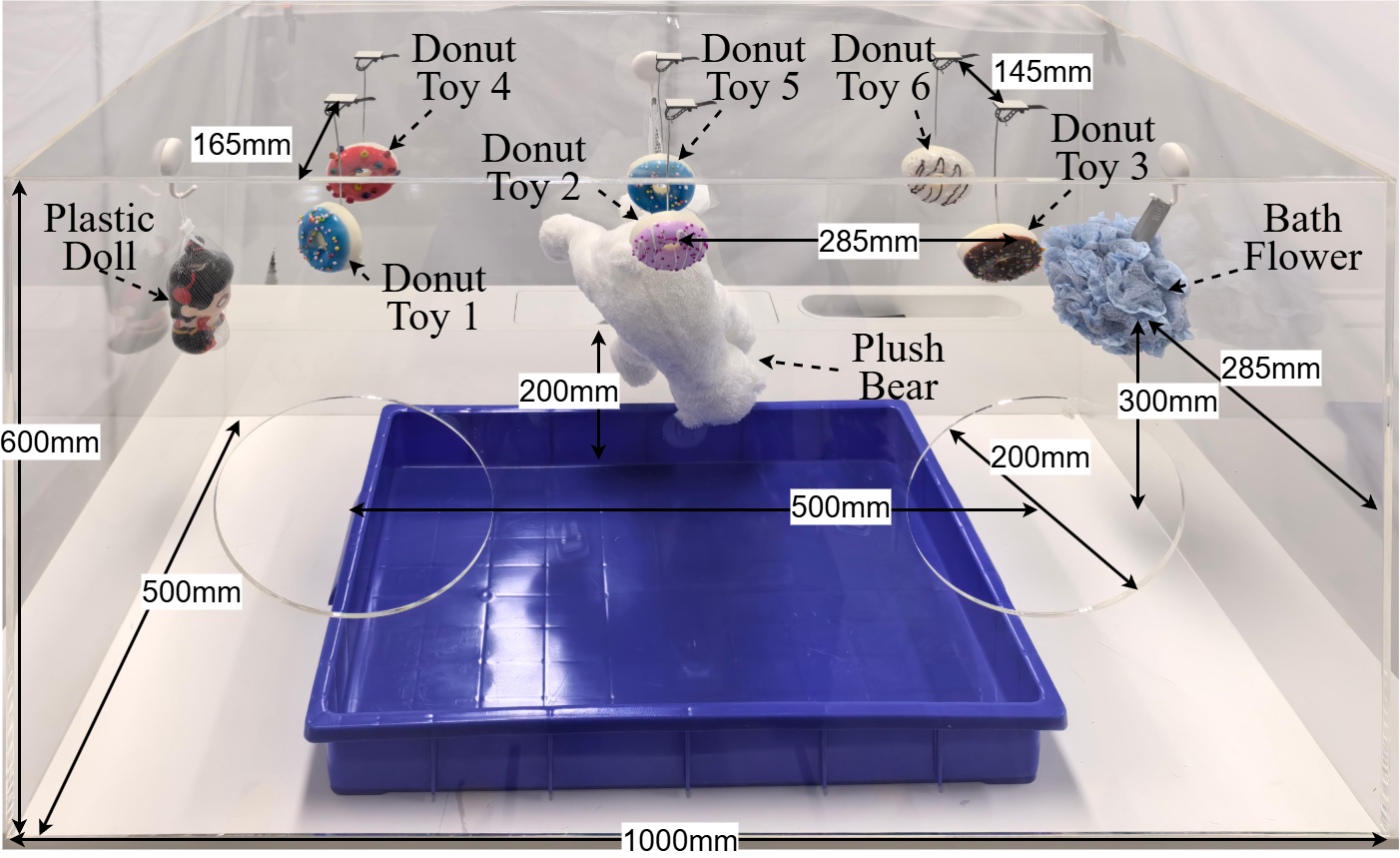

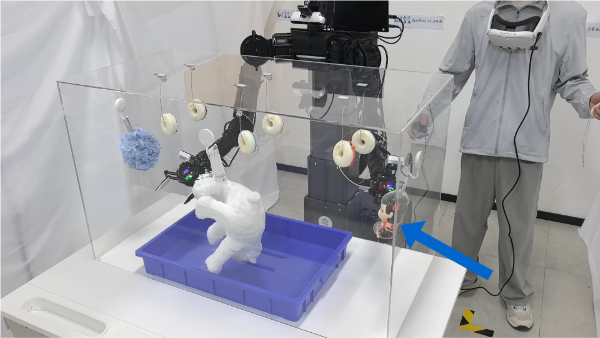

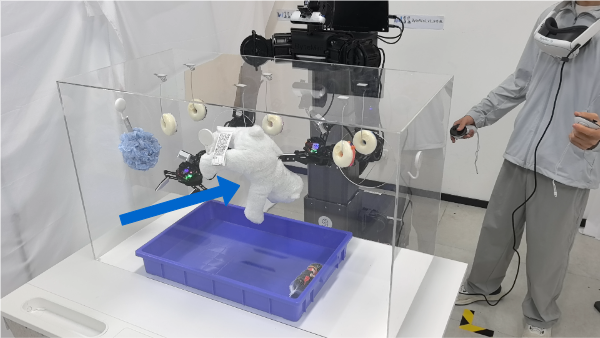

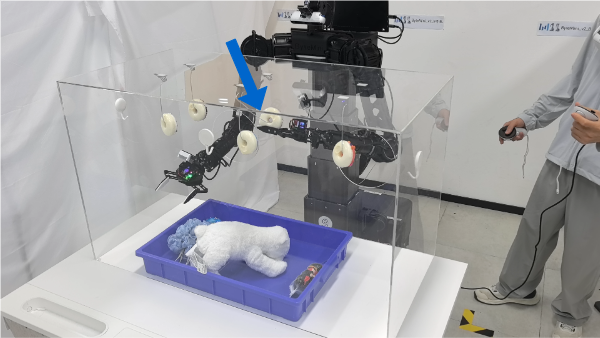

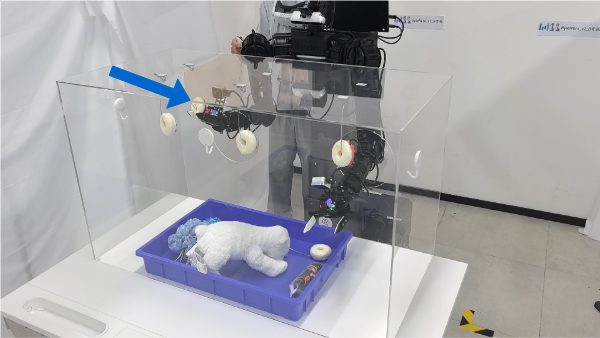

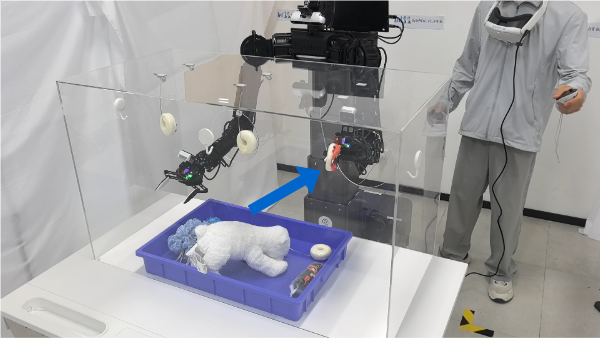

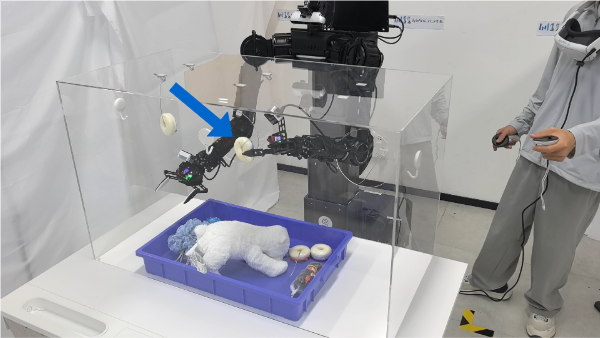

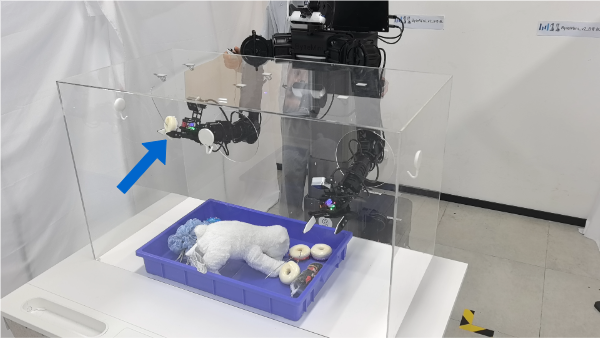

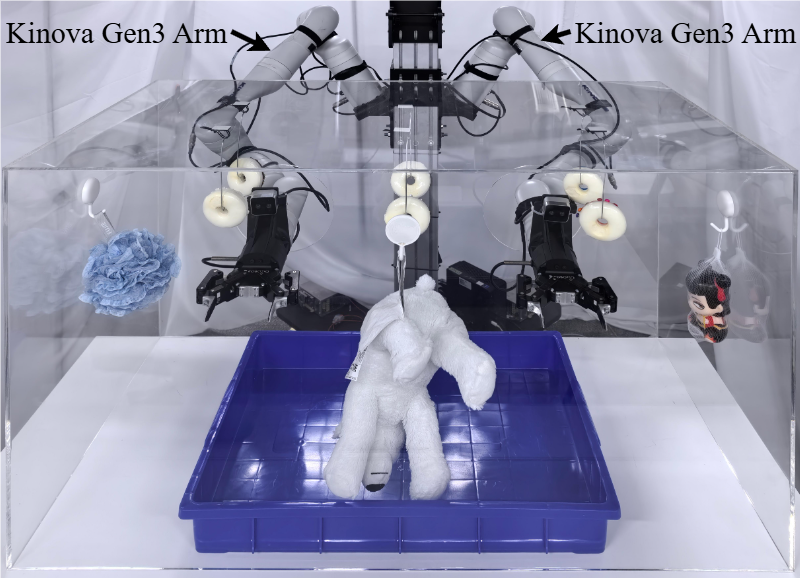

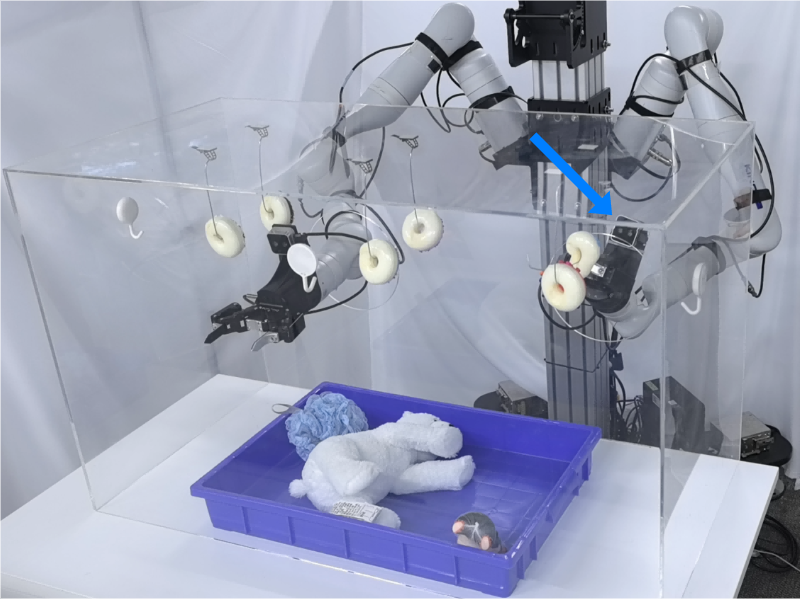

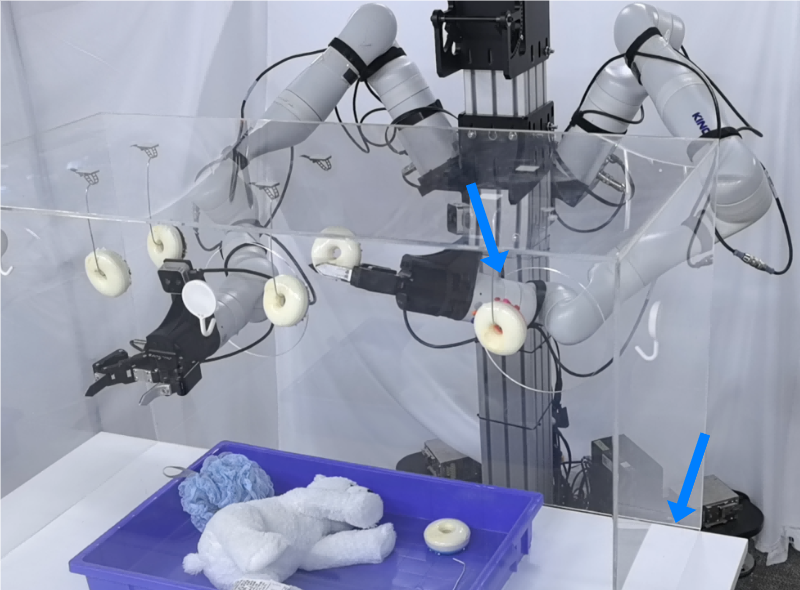

2) Confined-space test (glove box)

- They compared ByteMini (with ByteWrist) to a Kinova robot arm with a typical serial wrist.

- Both robots had to reach into a box through two round holes and grab nine objects placed around inside.

- Result: ByteMini total time ≈ 234 s; Kinova ≈ 476 s (about twice as long).

- Why was the serial wrist slower? It needed bigger arm movements to compensate for limited wrist range, sometimes had to pull the camera out to avoid bumping the box, and occasionally the longer arm links bumped the walls—each adding extra time.

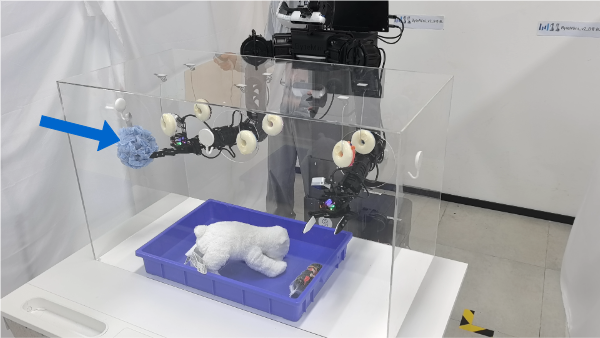

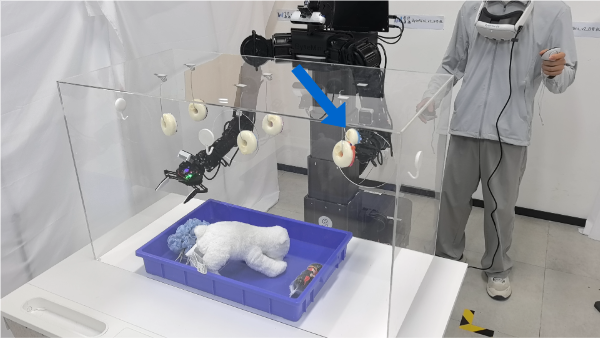

3) Dual-arm clothes hanging

- The robot had to pick up a hanger, cooperate with both hands to hang both shoulders of a shirt, switch hands, and hang the set on a bar.

- ByteMini collected 116 hours of data and also performed the full task automatically.

- The movements looked very natural and human-like, thanks to the wrist’s smooth RPY control.

What did they find, and why is it important?

Main findings:

- ByteWrist is very compact but still stiff and precise.

- It can perform clean, continuous roll–pitch–yaw motions, which is exactly what you want for human-like manipulation.

- It works especially well in tight spaces. In the glove box test, it was roughly twice as fast as a well-known serial-wrist robot under the same setup.

- It enables smooth dual-arm coordination on delicate, flexible items like clothing.

Why this matters:

- Many real-world tasks happen in cramped, messy, or delicate environments (homes, hospitals, factories).

- A small, strong, precise, and flexible wrist lets robots complete these tasks faster and more safely, with fewer collisions and more natural movements.

What could this change in the future?

- Home service robots: Reaching into shelves, cabinets, or drawers without knocking things over.

- Medical assistance: Maneuvering tools in tight spaces with high precision.

- Manufacturing and assembly: Working inside engines or crowded assemblies smoothly.

- Learning-based robotics: Better, more human-like motions for dual-arm tasks, making it easier to teach robots complex skills.

The authors plan to improve ByteWrist by expanding its motion range, reducing weight, and making the wiring even more reliable. Overall, ByteWrist is a strong step toward next-generation robot hands that move more like ours and work better in the real world.

Knowledge Gaps

Knowledge gaps, limitations, and open questions

Below is a concise list of missing, uncertain, or unexplored aspects in the paper that future work could address concretely.

- Quantitative stiffness and load capacity: No measurements of wrist stiffness (e.g., tip deflection under known loads), payload limits, or comparison against serial wrists; the “supporting ball” benefit is asserted but unquantified.

- Dynamic modeling and control: Only kinematics and a numerical Jacobian are provided; no dynamic model (inertia, Coriolis, friction) or model-based control/torque allocation for high-bandwidth motion is presented.

- Workspace characterization: The full 3D orientation workspace is not mapped; yaw range is not experimentally validated; the origin and derivation of β²+γ²<0.7² are not explained and appear task-specific.

- Singularity analysis: No paper of parallel/serial singularities, working modes, or condition numbers across the workspace; risk regions and recovery strategies remain unknown.

- Dexterity and isotropy: No manipulability/dexterity indices, Jacobian condition number distributions, or orientation accuracy uniformity over the workspace are reported.

- Closed-form Jacobian/forward kinematics: Solutions rely on Newton–Raphson and numerical differentiation; existence of closed-form or semi-analytic solutions and their computational benefits are unexplored.

- Convergence and robustness of numerical solvers: No analysis of Newton–Raphson convergence basins, sensitivity to initial guesses, multi-solution ambiguity, or runtime on embedded hardware.

- Calibration and parameter identification: No procedure for calibrating R1, R2, h, joint axes alignment, encoder offsets, or identifying model parameters to reduce geometric and assembly errors.

- Tolerance and misalignment sensitivity: Effects of manufacturing tolerances, joint axis non-concurrency, and assembly misalignments on accuracy and stiffness are not evaluated.

- Structural optimization: No multi-objective optimization (e.g., for motion range, stiffness, mass, and dexterity) over R1, R2, h, arc radius Rl, l1, l2; the fixed 90° arc choice is not justified against alternatives.

- Internal forces and load sharing: Static/kineto-static analysis of force distribution among the three branches, internal stresses, and implications for actuator sizing are absent.

- Fatigue and durability: Long-term wear of revolute pairs and the spherical support (friction, lubrication, backlash growth), fatigue of arc-shaped linkages, and lifecycle testing are not reported.

- Overconstraint risks: The added spherical support may overconstrain the mechanism; its impact on binding, friction, and micro-motion under misalignment is not analyzed.

- Backlash and hysteresis: Joint backlash and compliance, their effect on orientation precision and repeatability, and compensation methods are not studied.

- Actuator sizing and thermal behavior: No torque-speed margins, thermal limits, continuous vs peak performance, or thermal drift effects for QDD actuators under realistic loads/duty cycles.

- Energy and efficiency claims: “High efficiency” is not quantified; no mechanical efficiency, electrical power, or energy-per-task metrics are provided.

- Wiring and serviceability: Cable routing is acknowledged as future work; current reliability under repeated motion, bend radii, snag/collision risks, and maintainability are unaddressed.

- Safety and contact interaction: No wrist-level force/torque sensing, compliance control, or safe collision behavior—critical for confined spaces and deformable object manipulation.

- Tracking performance characterization: Only low-frequency circle tracking is shown; no bandwidth, phase margin, frequency response, or disturbance rejection tests; lag compensation is not explored.

- Accuracy and repeatability: Orientation accuracy and repeatability (ISO-like tests) over the workspace and under varying loads/speeds are not reported.

- Self-collision and joint-limit avoidance: No analysis or planner ensuring internal collision avoidance (between branches/links) and safe operation near joint limits.

- Yaw decoupling: Practical decoupling of R, P, Y is not analyzed; cross-coupling in control and its impact on trajectory tracking are not quantified.

- Comparative evaluation validity: The glove-box comparison is confounded (different platforms, grippers, cameras, bases, operator teleop); no statistical analysis or fairness controls; wrist-only ablations are missing.

- Robustness to disturbances: Effects of external disturbances (impacts, load changes), vibration modes, and resonance frequencies are not characterized.

- Environmental robustness: Operation in dusty, humid, or sterilizable settings (e.g., medical use) not assessed; sealing and contamination of the spherical joint are open issues.

- Scalability and generalization: Feasibility of scaling the design to smaller (minimally invasive) or larger payload applications, and material choices for different regimes, remain unexplored.

- Real-time computation footprint: CPU/GPU load, update rates, and latency breakdowns (communication, compute, actuation) for onboard execution are not reported; 0.06 s lag sources need decomposition.

- Control architecture: No discussion of feedforward, predictive, or disturbance observers; sensor fusion (e.g., IMU on the platform) to improve orientation estimation/control is not investigated.

- External wrench mapping: Mapping from desired end-effector torques to actuator torques (and limits) is not derived; capability to apply/measure specific wrenches is unknown.

- Failure modes and fault tolerance: No analysis of actuator/joint failure handling, graceful degradation, or diagnostics for safe operation.

- Reproducibility: CAD, code, controller parameters, and calibration data are not provided; replicability and community benchmarking are therefore limited.

- Anthropomorphism quantification: “Anthropomorphic” performance is qualitatively claimed but not quantified against human wrist kinematics/dexterity metrics.

Practical Applications

Immediate Applications

Below is a curated list of practical, deployable applications that leverage ByteWrist’s compact parallel wrist design, kinematic modeling, and demonstrated performance. Each item notes relevant sectors, likely tools/workflows/products, and the key assumptions or dependencies that influence feasibility.

- ByteWrist retrofit module for existing robot arms in confined-space tasks (Sector: robotics, manufacturing, logistics)

- Description: Integrate ByteWrist as a wrist upgrade on arms like UR, Kinova, or custom manipulators to improve dexterity and cycle time when reaching inside bins, cabinets, jigs, and engine bays.

- Tools/Products/Workflows: ByteWrist hardware kit, ROS drivers, forward/inverse kinematics + Jacobian control library, latency-aware controllers compensating ~0.06 s delay, calibration tools for R1/R2/h.

- Assumptions/Dependencies: Mechanical compatibility and mounting on target arms; reliable QDD actuator supply (e.g., RobStride); safe wire routing; control stack integration using the paper’s numerical Jacobian (Δθ ≈ 1e-3); adherence to range constraints (β²+γ²<0.7² rad²).

- Glovebox and cabinet manipulation in labs and factories (Sector: pharmaceuticals, chemicals, electronics, manufacturing)

- Description: Perform pick-and-place and tool handling inside gloveboxes or enclosed workcells with reduced collisions and faster reach-ins (paper shows ~2× speedup versus a serial wrist).

- Tools/Products/Workflows: Teleoperation via VR (Quest-based workflow as in paper), on-robot cameras (e.g., RealSense D405/D457), confined-space trajectory libraries, collision-aware motion planning.

- Assumptions/Dependencies: Material compatibility with lab environments; camera placement to avoid contact; operator training for teleop; safety interlocks for anthropomorphic motion.

- Bin picking and kitting in dense shelving (Sector: logistics, e-commerce fulfillment, warehouse automation)

- Description: Improve grasp success and cycle time in tightly packed bins/shelves by minimizing forearm reconfiguration and avoiding shelf collisions.

- Tools/Products/Workflows: Perception pipelines for close-range vision, gripper + wrist coordination, latency-compensation filters for high-speed control, end-effector tool-changers.

- Assumptions/Dependencies: Robust perception in clutter; gripper selection matched to object types; controller tuned for dynamic tasks where lag-induced errors increase with speed.

- Automotive and appliance assembly in cramped compartments (Sector: automotive, consumer appliances)

- Description: Cable routing, fastener manipulation, and inspection in constrained engine bays and appliance housings—reducing retraction/reposition cycles.

- Tools/Products/Workflows: Assembly task templates for RPY wrist motion, torque-limited controllers, slim end-effectors; fixture-aware trajectory generation using the paper’s kinematic models.

- Assumptions/Dependencies: Tool access and end-effector geometry; integration with existing quality control and safety standards; durability under industrial duty cycles.

- Hospital logistics and sterile storage handling (Sector: healthcare operations)

- Description: Fetch-and-place in narrow storage rooms and sterile cabinets without contact; reduce human load in routine logistics.

- Tools/Products/Workflows: Sanitizable wrist covers, sterile operation protocols, slow-speed control modes where latency-induced errors are negligible.

- Assumptions/Dependencies: Hygiene and sterilization requirements; staff acceptance; safety certification for mobile manipulation in clinical spaces.

- Dual-arm deformable object manipulation for laundry/wardrobe tasks (Sector: home robotics, service robotics)

- Description: Clothes-hanging and garment handling (demonstrated in GR-3), exploiting anthropomorphic, chest-front dual-arm coordination.

- Tools/Products/Workflows: VLA model rollout pipelines (e.g., GR-3 data collection/training), dual-arm coordination controllers, task-specific policies for deformable objects.

- Assumptions/Dependencies: Reliable perception of deformable items; continuous operation without cable snag; safe human-robot interaction policies in domestic settings.

- Academic research testbed for parallel wrist kinematics and dual-arm manipulation (Sector: academia, education)

- Description: Use ByteWrist in labs for research on confined-space dexterity, deformable object manipulation, anthropomorphic motion, and VLA training.

- Tools/Products/Workflows: Open-source kinematics/Jacobian implementations, benchmark protocols (e.g., glovebox task), simulator plugins, curriculum modules on Newton–Raphson and Jacobian numerics.

- Assumptions/Dependencies: Access to hardware; reproducible calibration; careful step-size selection for numerical stability (Δθ ≈ 1e-3 as reported).

- Safety and performance benchmarking for confined-space robot wrists (Sector: policy, standards, testing)

- Description: Establish acceptance tests and metrics (e.g., glovebox reach tasks, collision rates, cycle time) for procurement and certification.

- Tools/Products/Workflows: Standard test scenarios, reporting templates, safe operating envelope definitions consistent with wrist range constraints and latency characteristics.

- Assumptions/Dependencies: Stakeholder buy-in (manufacturers, labs); alignment with existing robot safety standards; clear definitions of anthropomorphic motion that avoids pinch/collision hazards.

Long-Term Applications

The following applications are promising but require further research, scaling, certification, or adaptation of materials and control stacks before broad deployment.

- Minimally invasive and endoscopic surgical wrists (Sector: healthcare, surgical robotics)

- Description: Adapt ByteWrist’s compact parallel mechanism for high-precision RPY in body cavities, with enhanced stiffness and controlled force transmission.

- Tools/Products/Workflows: Sterilizable, biocompatible materials; miniaturized actuators; haptic feedback; validated force control; surgical navigation integration.

- Assumptions/Dependencies: Regulatory approvals (FDA/CE); rigorous safety, sterilization, and reliability; reduced latency and higher control bandwidth; extensive clinical trials.

- Hazardous-environment remote manipulation (Sector: nuclear decommissioning, chemical processing, defense EOD)

- Description: Glovebox and confined-space handling in radiation or corrosive environments, replacing human exposure with teleoperation or autonomy.

- Tools/Products/Workflows: Radiation-hardened/chemically resistant components; sealed wire routing; haptic teleoperation; robust vision under harsh conditions.

- Assumptions/Dependencies: Environmental hardening; long service-life; specialized safety protocols; policy frameworks for remote intervention.

- Space robotics for maintenance in cramped spacecraft modules (Sector: aerospace)

- Description: Manipulation in tight spacecraft compartments and experimental racks, where compactness and stiffness are critical.

- Tools/Products/Workflows: Space-rated materials and lubricants; vacuum-compatible actuation; radiation-tolerant electronics; teleoperation/autonomy workflows.

- Assumptions/Dependencies: Qualification for launch and space ops; integration with spacecraft power/data systems; thermal management in vacuum.

- Consumer-grade humanoid/service robots with anthropomorphic wrists (Sector: consumer robotics, smart home)

- Description: Widespread household robots capable of nuanced, human-like wrist motions for everyday tasks (laundry, kitchen organization, cabinet storage).

- Tools/Products/Workflows: Cost-optimized ByteWrist variants; robust cable management; safety-certified interaction; VLA models trained on diverse home datasets.

- Assumptions/Dependencies: Price/performance suitable for consumers; long-term reliability; home safety certification; privacy-preserving data collection for training.

- Micro-assembly and precision manufacturing in dense fixtures (Sector: electronics, medical devices)

- Description: Autonomous manipulation with minimal retraction cycles inside tightly spaced fixtures, leveraging high stiffness and compact RPY motion.

- Tools/Products/Workflows: High-resolution vision; fine-grained force/torque sensing; advanced motion planning with numerical Jacobians; multi-robot coordination.

- Assumptions/Dependencies: Perception robustness at small scales; end-effector miniaturization; integration with MES/quality systems; cycle-time guarantees.

- Advanced prosthetic wrists inspired by parallel mechanisms (Sector: healthcare, assistive tech)

- Description: Lightweight, stiff, anthropomorphic prosthetic wrist offering precise RPY motion with reduced bulk compared to serial designs.

- Tools/Products/Workflows: Low-mass actuation, energy-efficient control, EMG/nerve interfaces; ergonomic designs and cosmetics.

- Assumptions/Dependencies: Significant weight reduction; user comfort and safety; battery life; clinical fitting and reimbursement pathways.

- Standardization of “confined-space dexterity” benchmarks and certifications (Sector: policy, standards)

- Description: Formalize metrics, test setups, and reporting to compare serial vs. parallel wrists in constrained environments across industries.

- Tools/Products/Workflows: Multi-sector working groups; public datasets (e.g., GR-3), standardized glovebox tasks, collision metrics, latency/error reporting.

- Assumptions/Dependencies: Industry/academia consensus; harmonization with ISO/ANSI robot safety standards; longitudinal field data.

- Integrated AI workflows for autonomous dual-arm manipulation in clutter (Sector: software, robotics AI)

- Description: Combine ByteWrist hardware with VLA models (e.g., GR-3) for robust, generalizable autonomy in deformable object handling and confined tasks.

- Tools/Products/Workflows: Scalable data collection pipelines; sim-to-real transfer; policy distillation for latency-aware control; failure recovery strategies.

- Assumptions/Dependencies: Larger, diverse datasets; improved generalization; safe online learning; dependable perception in occlusion-heavy scenes.

Glossary

- Anthropomorphic: Human-like in motion or form, enabling robot movements that resemble human wrists. "ByteWrist, a novel highly-flexible and anthropomorphic parallel wrist for robotic manipulation."

- Arc-shaped end linkage: A curved linkage at the end of the mechanism that transmits motion and force to the platform. "arc-shaped end linkages that optimize force transmission and expand motion range"

- Attitude: The orientation of a body in 3D, often represented by RPY angles or rotation matrices. "This paper adopts the RPY method to describe the attitude of the parallel platform."

- Dual-arm cooperative manipulation: Coordinated use of two robotic arms to perform a task together. "dual-arm cooperative manipulation tasks, outperforming Kinova-based systems."

- End effector: The tool or device at the end of a robot arm that interacts with the environment. "robotic end-effectors, especially robotic wrists."

- Forward kinematics: Computing the end-effector pose from joint variables. "For the forward kinematics part, the inputs are , , , and the outputs are RPY angles of the parallel platform."

- Glove box: A sealed box allowing manipulation inside via access holes, used to test confined-space tasks. "A glove box shown in Fig. \ref{fig:5} is designed for this experiment."

- Inverse kinematics: Computing joint variables that achieve a desired end-effector pose. "For inverse kinematics, the input is RPY angles of the parallel platform, and the output is , and ."

- Jacobian matrix: A matrix relating joint velocities to end-effector angular rates; used for differential control and sensitivity. "proposes a numerical solution for the Jacobian matrix to ensure precise control."

- Newton-Raphson method: An iterative numerical method to solve nonlinear equations. "the Newton-Raphson method is adopted herein for iterative solution."

- Omnidirectional mobile platform: A drive system that can move in any planar direction and rotate. "3-DoF omnidirectional mobile platform for flexible movement."

- Parallel mechanism: A mechanism where multiple kinematic chains connect base and platform in parallel. "ByteWrist adopts a three-stage motor-driven parallel mechanism, combined with arc-shaped end linkages and a central supporting ball."

- Parallel robotic wrist: A wrist mechanism actuated via parallel branches for stiffness and accuracy. "parallel robotic wrists, which actuate the end platform through multiple parallel branches"

- Quasi-Direct Drive (QDD): Actuation using low gear ratios and high-torque motors for low friction and high backdrivability. "the prototype of ByteWrist adopts Quasi-Direct Drive \cite{QDD, QDD1, QDD2} based actuators manufactured by \href{https://robstride.com/}{RobStride Dynamics}."

- Revolute pair: A rotational joint between two links allowing relative rotation about an axis. "are connected via revolute pairs."

- Roll-Pitch-Yaw (RPY): Three-angle parameterization of orientation: rotation about X (roll), Y (pitch), and Z (yaw) axes. "achieving precise RPY (Roll-Pitch-Yaw) motion of the end platform while maintaining a small structural footprint."

- Root mean square error (RMSE): A scalar metric of error magnitude computed as the square root of the mean squared error. "A series of step sizes ($1e-1$, $1e-2$, ..., $1e-7$) are selected to calculate both the maximum error and root mean square error (RMSE) of the elements in Jacobian matrix."

- Rotation matrix: A 3×3 matrix representing orientation transformation between frames. "The rotation matrix describing the attitude transformation of the parallel platform is expressed in (5)."

- Spherical joint: A ball-and-socket joint allowing rotation about all three axes. "connected to the platform via a spherical joint."

- SRS (Spherical-Revolute-Spherical): A manipulator joint sequence with spherical, revolute, and spherical joints. "7-DoF in SRS (Spherical-Revolute-Spherical) configuration with ByteWrist as wrist modules."

- Tele-operation: Remote operation of a robot by a human via control devices. "The ByteMini robot is tele-operated to extend both arms into the glove box."

- Unstructured environments: Real-world settings lacking regular geometry or predictable constraints. "complex and unstructured settings such as home services, medical assistance, and precision assembly"

- Vision-Language-Action (VLA) model: A model integrating vision, language, and action for robot policy learning. "GR-3\cite{GR3, GR2} is a large-scale vision-language-action (VLA) model"

Collections

Sign up for free to add this paper to one or more collections.