- The paper introduces a dual demonstration system that simplifies robot programming by mimicking both motion and jig operations.

- It employs a mobile manipulator with ROS integration and custom experimental jigs, achieving 100% task-success in practical tests.

- The study demonstrates enhanced efficiency and flexibility in chemical experiment automation while noting the need for improved adaptive planning.

Robotic Automation for Chemical Experiments via Dual Demonstration

This paper introduces a novel robotic system designed for the automation of chemical experiments. The key innovation lies in the concept of "dual demonstration," where a chemist demonstrates both the robot's motions and the operation of experimental jigs. This approach aims to simplify robot programming and enhance the flexibility of automated experimental procedures. The authors validate their concept through the development of a chemical-experiment-automation system and experiments focusing on polymer synthesis.

System Design and Implementation

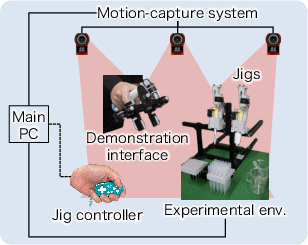

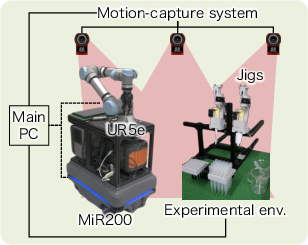

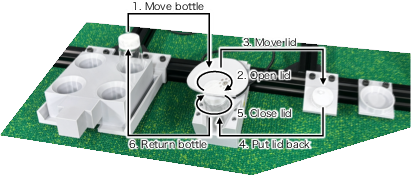

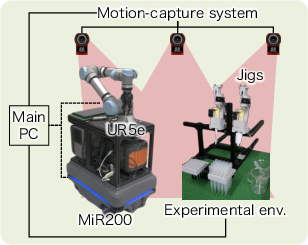

The chemical-experiment-automation system comprises several key components:

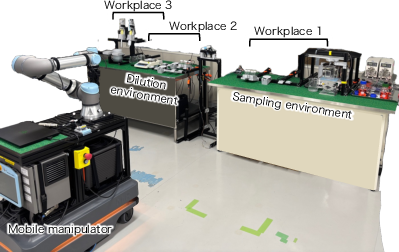

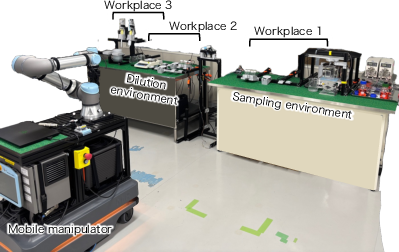

- Mobile Manipulator: A MiR200 mobile robot equipped with a UR5e robotic arm and a ROBOTIS HAND RH-P12-RN gripper. The mobile base allows the robot to navigate between different workstations within the experimental environment.

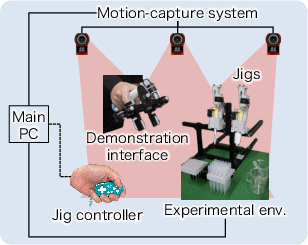

- Motion-Demonstration Interface: An interface designed to mimic the structure of the robot's gripper, enabling chemists to intuitively demonstrate robot motions. An Omron rotary encoder captures finger positions.

- Experimental Jigs: A set of custom-designed jigs for specific tasks such as pipetting, bottle mounting, flow plumbing, and bottle holding. These jigs are designed to be compatible with the two-fingered gripper and are controlled via the ROS.

- Motion-Capture System: An OptiTrack Flex13 optical motion-capture camera system is used to track the position of the motion-demonstration interface.

- ROS Integration: All components are integrated using the ROS, providing a unified framework for control and data acquisition.

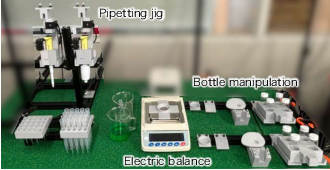

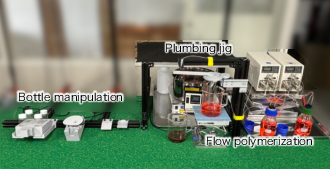

Figure 1: Overview of developed chemical-experiment-automation system.

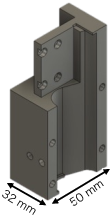

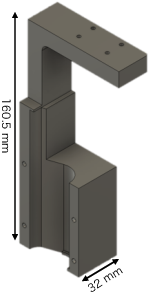

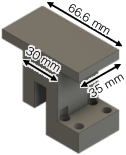

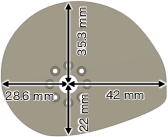

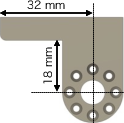

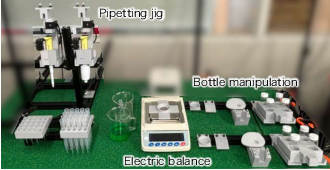

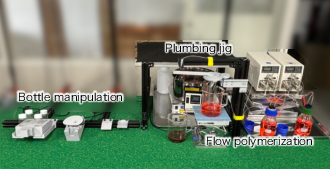

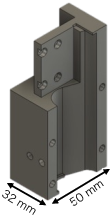

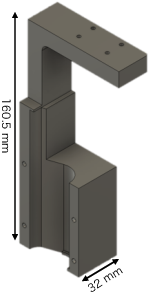

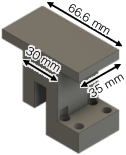

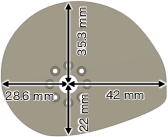

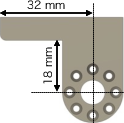

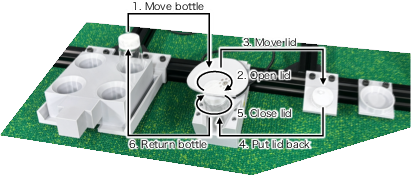

The experimental jigs utilize Robotis Dynamixel XM430-W350 servo motors controlled via U2D2 interfaces and employ a finite state machine (FSM) approach for precise control. The authors detail the design and operation of each jig, including the pipetting jig (Figure 2), bottle-mounting jig (Figure 3), flow-plumbing jig (Figure 4), and bottle-holder jig (Figure 5).

Figure 2: Pipetting jig.

Experimental Evaluation

The authors conducted two sets of experiments to evaluate the performance of the proposed system:

- Simple-Task-Automation Experiment: This experiment focused on evaluating the system's ability to reproduce basic tasks such as bottle manipulation and pipetting. The results demonstrated a 100% task-success rate and high fidelity in motion reproduction, as measured by the Hausdorff distance between demonstrated and robot-executed trajectories (Table 1 and 2).

- Laboratory-Automation Experiment: This experiment simulated a more complex polymer-synthesis workflow, involving polymer sampling, bottle manipulation, and dilution via pipetting. The mobile manipulator successfully completed the entire sequence of experimental actions in all trials. The volumes of liquids transferred during the dilution process were also measured, demonstrating accurate liquid handling.

Figure 6: Experimental environment for simple experimental tasks.

Figure 7: Overview of experimental environment consisting of two workspaces: (a) polymer sampling and (b) polymer dilution.

Implications and Future Directions

This work has several important implications for the field of laboratory automation:

- Simplified Robot Programming: The dual-demonstration concept provides a more intuitive and accessible approach to robot programming for chemists who may not have expertise in robotics.

- Enhanced Flexibility: The integrated system of motion demonstration and experimental jigs enables flexible adaptation to a wide range of experimental conditions.

- Improved Efficiency: The system demonstrates the potential to automate complex experimental procedures, improving efficiency and throughput in chemical research.

The authors acknowledge several limitations of their current system, including the lack of adaptive motion planning and the reliance on accurate position estimation from the motion-capture system. They propose future work to address these limitations by incorporating perception capabilities, imitation-learning frameworks, and techniques for automatic segmentation of demonstrations.

Conclusion

The paper presents a compelling approach to chemical-experiment automation through the concept of dual demonstration. The developed system demonstrates promising results in terms of task-success rates, motion reproducibility, and the ability to automate complex experimental workflows. Future work will focus on addressing the limitations of the current system and further enhancing its robustness and adaptability.