- The paper introduces a DDPM-based framework that reinterprets mesh generation as a denoising task to create polycube structures from complex geometries.

- It leverages a U-Net architecture with parameterized Markov chains to accurately transform input shapes into high-quality hexahedral meshes.

- The approach eliminates reliance on predefined templates, enhancing scalability and efficiency in isogeometric analysis workflows.

DDPM-Polycube: An Advanced Approach to Hexahedral Mesh Generation

The paper "DDPM-Polycube: A Denoising Diffusion Probabilistic Model for Polycube-Based Hexahedral Mesh Generation and Volumetric Spline Construction" (2503.13541) presents an innovative approach for generating high-quality hexahedral (hex) meshes and constructing volumetric splines. It introduces a generative polycube creation method based on denoising diffusion probabilistic models (DDPM).

Introduction and Motivation

The construction of volumetric parameterization for isogeometric analysis (IGA) remains challenging, especially when involving complex B-Rep models. Hex meshes offer numerous advantages, such as fewer elements for the same accuracy and better compatibility with spline construction. However, generating high-quality hex meshes for complex geometries is difficult. Existing methods, such as DL-Polycube, require predefined polycube structure templates and extensive training data but fail to generalize well to varied topologies. This research proposes DDPM-Polycube as a novel method to address these challenges by viewing the deformation as a denoising task.

Methodology

DDPM-Polycube Algorithm

The work defines the deformation from input geometry to polycube structures as a denoising task in generative modeling. It progressively reconstructs polycube structures from input geometry by removing non-standard Gaussian noise.

Figure 1: DDPM-Polycube pipeline illustrating conversion processes, model strategy, and diffusion steps.

DDPM-Polycube models leverage diffusion models to capture the deformation characteristics of geometric primitives. The diffusion process includes standard Gaussian and adjustment terms to modify data distribution, allowing generation of polycube structures. The polycube structures are then used for surface segmentation and parametric mapping to generate hex meshes and construct volumetric splines satisfying IGA requirements.

Diffusion Process

The paper presents an innovative diffusion process equation designed for hex mesh generation. It incorporates a parameterized Markov chain for reverse diffusion to generate polycube structures.

Model Training

The DDPM-Polycube model employs a U-Net framework with specialized convolutional layers to predict deformation and noise, maintaining geometric integrity. Training uses mean squared error between true noise and predicted noise. Advanced feature extraction includes representing input geometries in a three-channel matrix compatible with the model.

Figure 3: DDPM-Polycube model architecture with ResNet-enhanced feature extraction.

Results

The DDPM-Polycube model demonstrates ability to generate polycube structures from various complex geometries, including those beyond its training set.

Figure 4: Training convergence illustrating model loss over iterations.

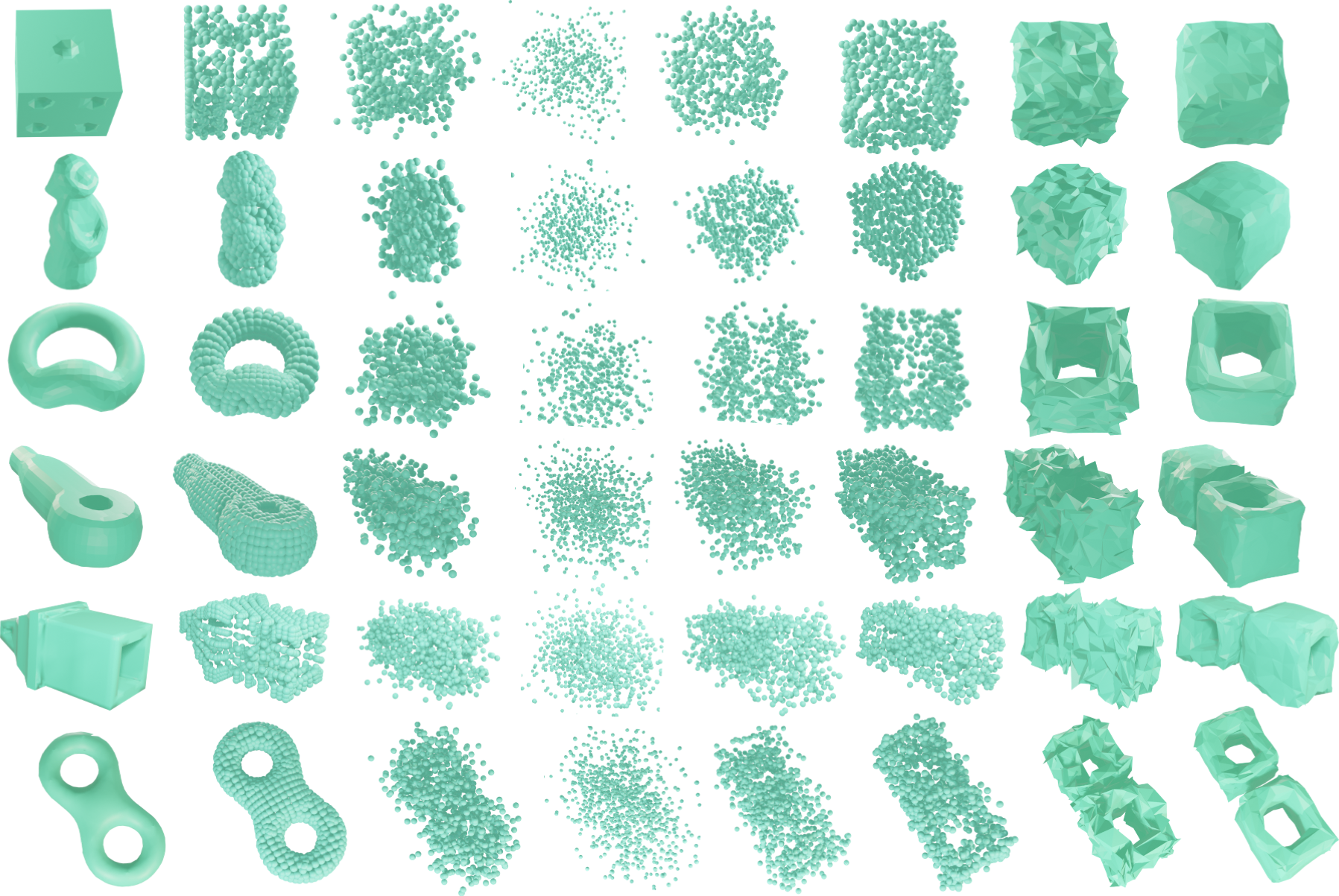

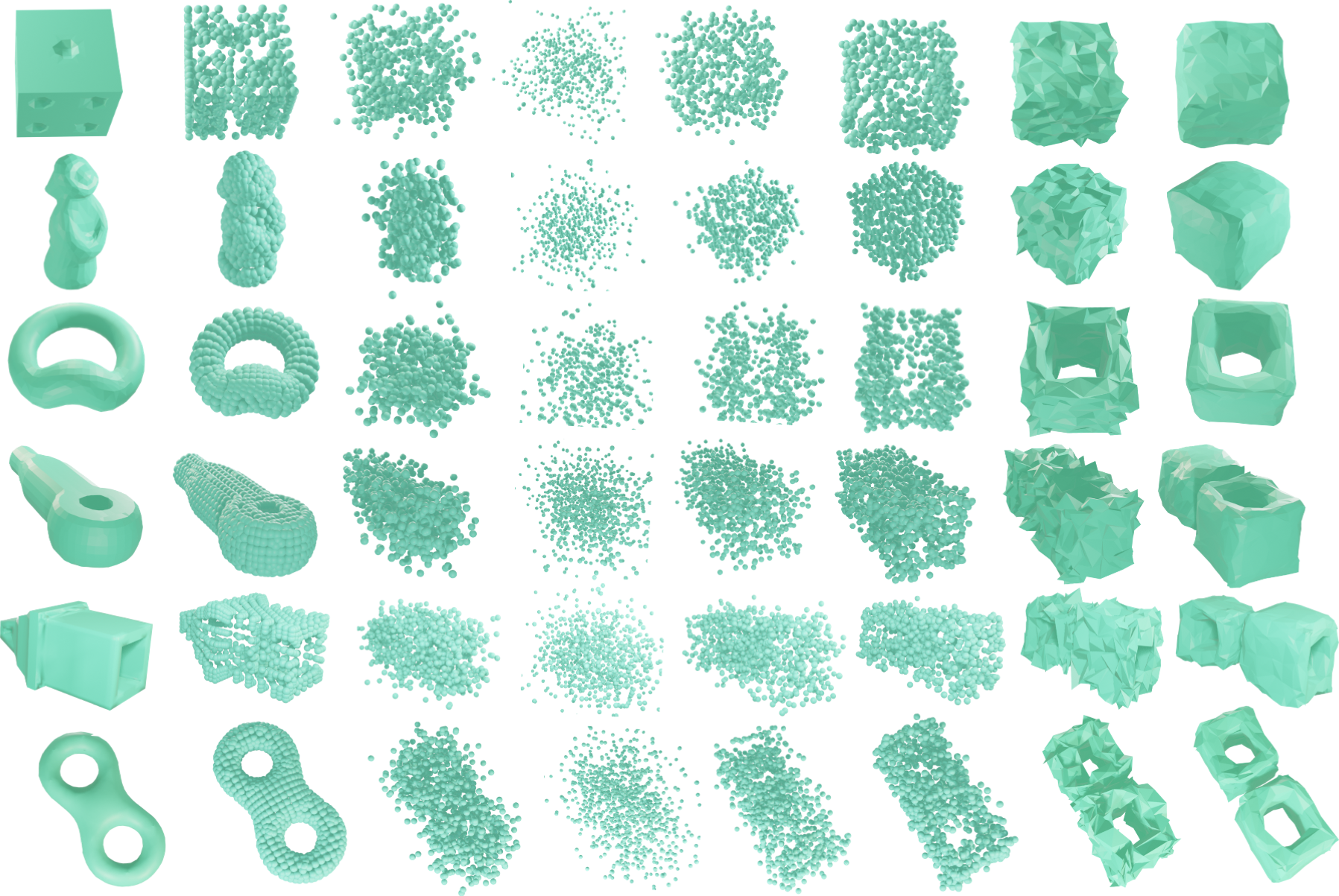

The algorithm successfully handles the generation of polycube structures across diverse genus levels. Testing against genus-0, genus-1, and complex geometries reveals its robust generalization capabilities.

Figure 5: Polycube structures for various geometries, demonstrating the model's adaptability.

Figure 6: DDPM-Polycube algorithm's proficiency with complex geometric models across different genus levels.

Mesh Generation and Spline Construction

After generating polycube structures, the paper describes transforming these into hex meshes and constructing volumetric splines. The spline construction meets high-quality criteria required for IGA.

Figure 7: Illustrates polycube structures, hex meshes, and spline construction with quality analyses.

Conclusion

The DDPM-Polycube represents a significant advancement in generative modeling for mesh generation and spline construction. It circumvents reliance on predefined templates, allowing broader application across varying topologies. The future directions emphasize increasing model extensibility to higher-genus geometries and refining noise modeling for more robust polycube structures. Integrating this model with CAD platforms and enhancing dataset variety promise greater automation and efficiency in IGA workflows.

The implications of this research extend to potential scalability across different mesh types, paving the way for refined computational geometry practices and advancing computational mechanics applications.