- The paper demonstrates an integrated pipeline that combines CAD modeling, IGA, and hybrid manufacturing to achieve over 50% weight reduction and 75% compliance reduction compared to solid blades.

- The paper presents detailed parametric microstructural designs using B-spline trivariates for smooth continuity and graded mechanics that reduce excessive deflections under centrifugal loads.

- The paper validates manufacturability via LPBF and 5-axis CNC machining, with tomography confirming high fidelity and notable improvements in static stiffness and vibrational performance.

Design, Analysis, and Hybrid Manufacturing of Microstructured Blade-Like Geometries

Introduction and Motivation

This paper presents a comprehensive pipeline for the design, optimization, manufacturing, and inspection of microstructured blade-like geometries, with a focus on aeronautical blisk blades. The central thesis is the replacement of traditional solid components with porous, heterogeneous microstructured designs that maintain mechanical functionality while significantly reducing material usage and weight. The approach leverages advanced CAD modeling, isogeometric analysis (IGA), additive manufacturing (specifically laser powder bed fusion, LPBF), and precision 5-axis CNC machining, culminating in rigorous inspection via tomography.

Volumetric Microstructural Design

The design methodology centers on embedding parametric microstructural tiles within the free-form volumetric domain of the blade. Tiles are constructed as B-spline trivariates, enabling smooth C1 continuity across the lattice and compatibility with IGA frameworks. Two principal microstructure families are explored: axis-parallel cross tiles and diagonal-arm tiles, both with tunable parameters such as arm thickness and roundness. The microstructure is confined within an offset shell to facilitate subsequent CNC finishing.

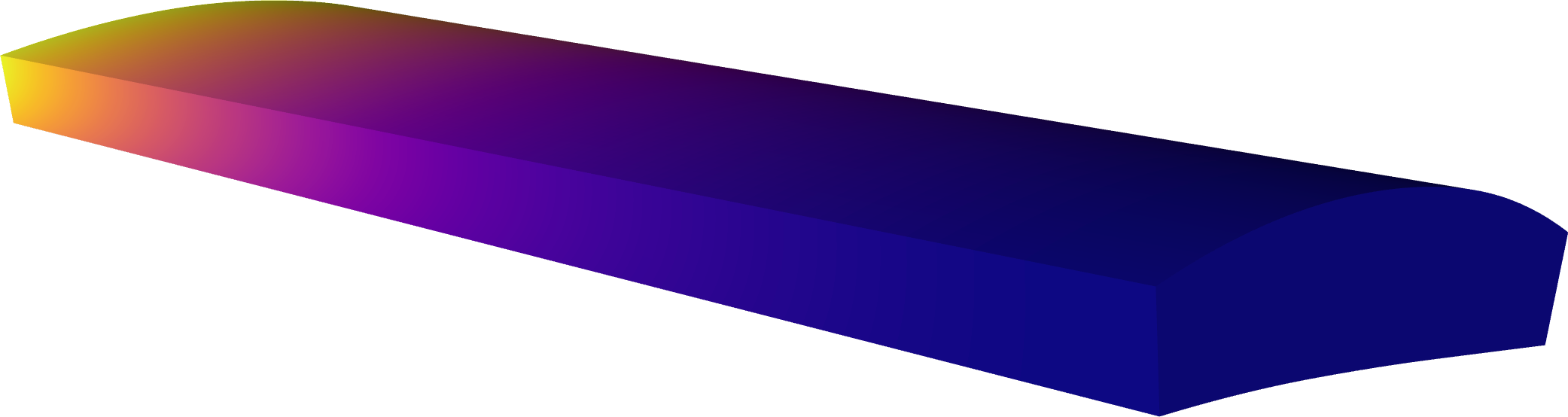

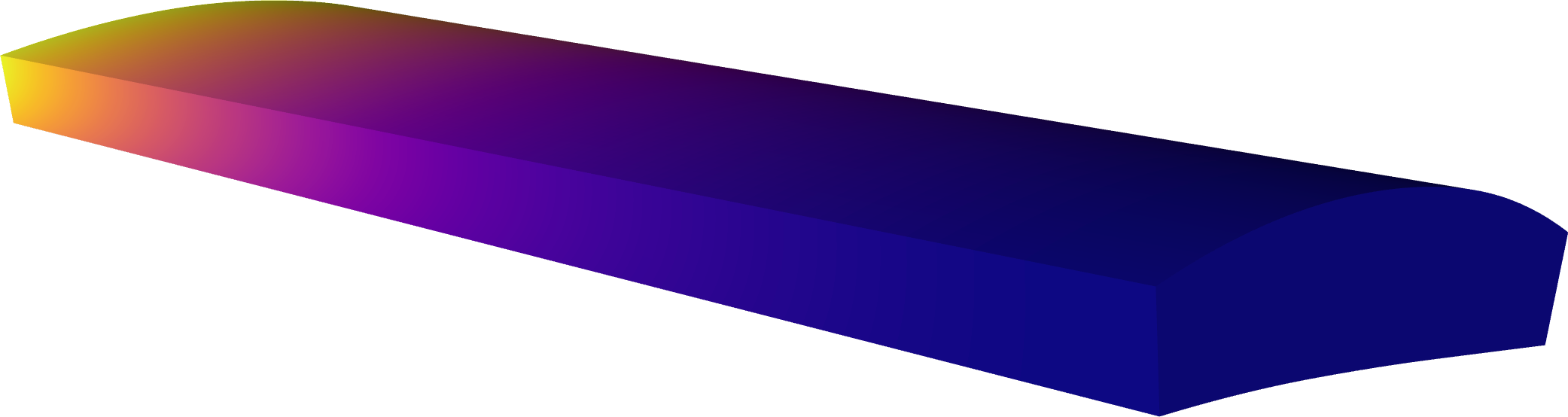

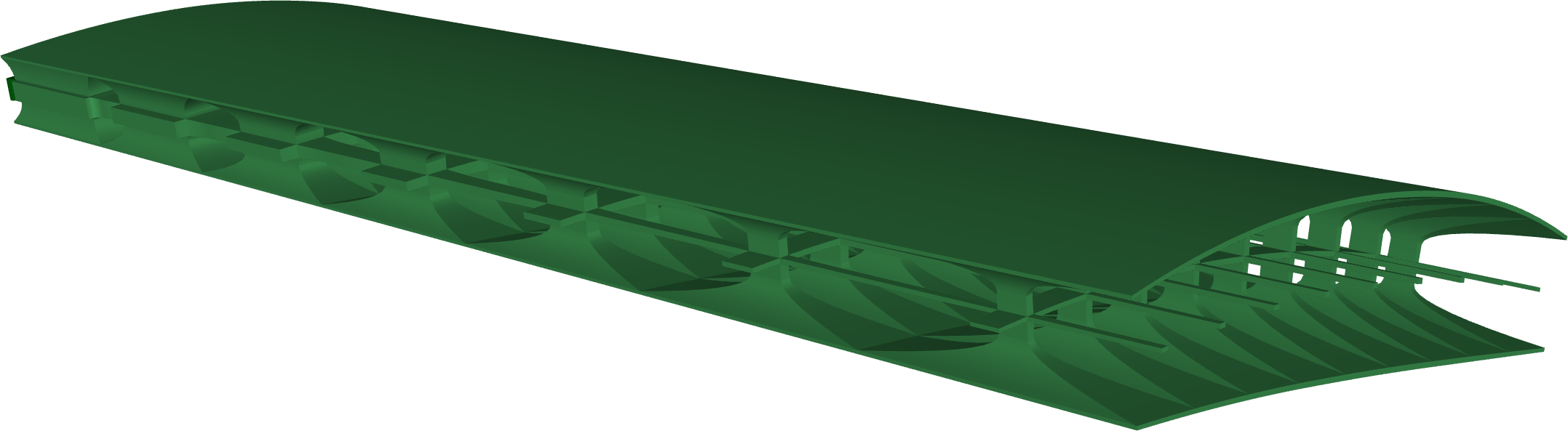

Figure 1: Optimized arm thicknesses in microstructural tiles, with thick arms near the rotation axis and thin arms at the blade tip, and the corresponding optimized blade geometry.

Auxetic microstructures, characterized by negative Poisson's ratio, are also considered. A modified 3D double-V auxetic cell is designed to be manufacturable via LPBF without internal support structures, provided strut angles remain below process-specific thresholds.

Analysis and Microstructural Optimization

Mechanical analysis is performed under centrifugal loading, the dominant operational stressor for turbine blades. Both FEM (using beam elements for slender struts) and IGA (directly on spline representations) are employed. Material properties correspond to Inconel 718, the industrial standard for such components.

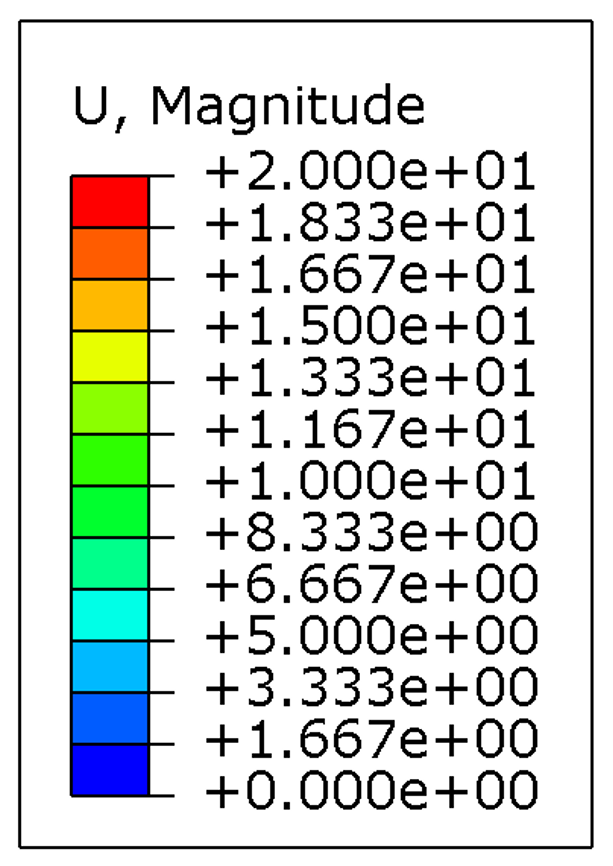

Figure 2: Displacement magnitude contourplots for two auxetic microstructures, illustrating the effect of spatial grading on deformation.

Key findings include:

- Uniform auxetic microstructures exhibit excessive tip deflection under load, indicating unsuitability for this application.

- Graded microstructures, with increased strut thickness near the blade root, halve the maximum deflection compared to uniform designs.

- Automatic gradient-based optimization (using Splinepy, G+Smo, and SciPy) of arm thicknesses yields designs with over 50% weight reduction and more than 75% compliance reduction relative to solid blades.

Hybrid Manufacturing and Inspection

Manufacturing integrates LPBF for the shell and internal microstructure, followed by 5-axis CNC machining for surface finishing. The LPBF process uses Inconel 718 powder with controlled particle size distribution and raster strategies to minimize residual stresses. Five blade specimens with distinct microstructures are fabricated and subsequently machined using ball-end milling tools under optimized conditions.

Dynamic behavior is assessed via hammer testing, both pre- and post-machining. Static and dynamic stiffness measurements reveal that thinner microstructures (MS1D, MS1R) outperform both thicker microstructures and solid blades in terms of stiffness and vibrational response. The solid blade consistently exhibits the lowest static stiffness and natural frequency.

Tomography analysis is conducted to quantify geometric deviations between the CAD model and manufactured specimens. Internal microstructures MS1R and MS2R demonstrate superior manufacturing fidelity (deviations ≤ 1.2 mm), while auxetic and other designs suffer from process-induced inaccuracies due to bar dimensions and orientations incompatible with LPBF constraints.

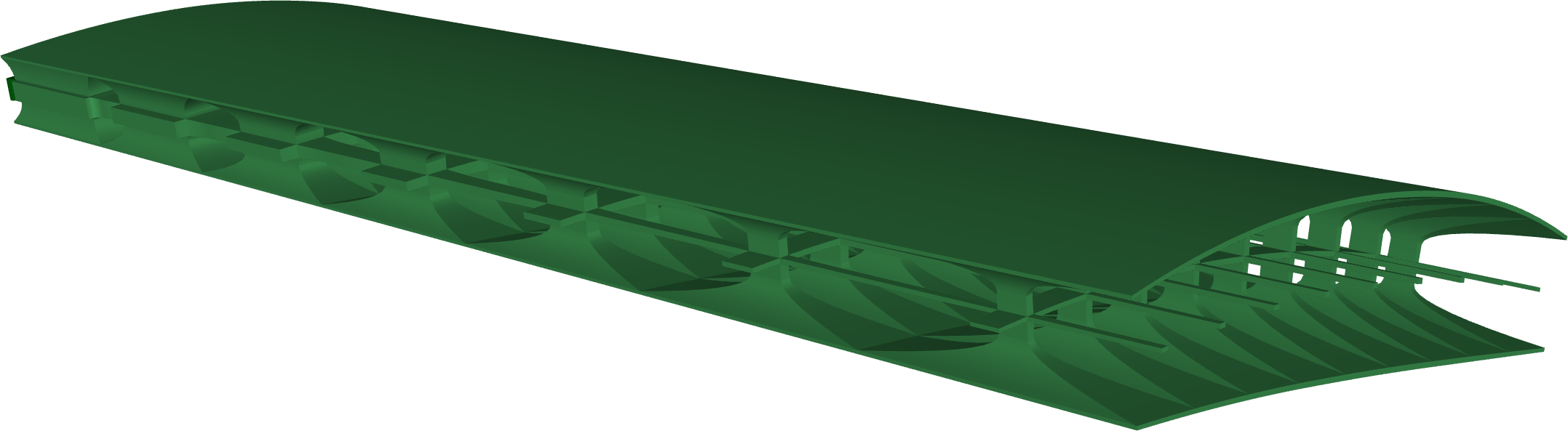

Figure 3: Tomography analysis of five sample designs, showing alignment between CAD and printed structures; green indicates high fidelity.

Implementation Considerations and Limitations

- Parameterization: The pipeline supports global and local control of tile parameters, but full per-tile optimization with continuity constraints remains an open challenge for large-scale lattices.

- Material Models: Only homogeneous Inconel 718 is considered, though the framework is extensible to graded or multi-material designs.

- Manufacturing Constraints: LPBF imposes strict limits on minimum feature size and strut orientation; support removal strategies are critical for enclosed microstructures.

- Analysis Validity: Large deformations in auxetic designs violate linear elasticity assumptions, limiting the accuracy of FEM predictions for these cases.

- Comparison to Topology Optimization: Achieved weight reductions (26–50%) are competitive with topology-optimized bladed discs, but the presented pipeline uniquely integrates manufacturability and post-processing constraints.

Implications and Future Directions

The demonstrated pipeline enables the systematic design and production of lightweight, functionally equivalent blade-like components with substantial material savings. The integration of IGA-compatible microstructural modeling, automated optimization, and hybrid manufacturing addresses key barriers to industrial adoption of microstructured designs. Future work should focus on:

- Scaling optimization to per-tile parameterization with continuity enforcement.

- Incorporating multi-material and functionally graded microstructures.

- Extending the approach to other high-performance free-form components (e.g., gears, rotors).

- Further benchmarking against topology optimization under real manufacturing constraints.

Conclusion

This work establishes a unified framework for the design, analysis, manufacturing, and inspection of microstructured blade-like geometries. The pipeline achieves significant reductions in material usage and weight while maintaining mechanical performance, validated through simulation, physical testing, and tomography. The approach is extensible to a broad class of engineering components and sets the stage for future advances in lightweight, high-performance manufacturing.