- The paper introduces the OPTSORT algorithm which uses simulation-driven MILP to optimize destination mapping and workforce allocation for improved parcel throughput.

- It integrates a high-fidelity digital twin to mimic real-world sorting center operations, allowing iterative refinement based on real-time demand and labor availability.

- Results demonstrate a 2% increase in parcel processing in high-load scenarios and achieve zero recirculation rates in restricted layouts, highlighting operational robustness.

A Simulation Driven Optimization Algorithm for Scheduling Sorting Center Operations

The research paper "A Simulation Driven Optimization Algorithm for Scheduling Sorting Center Operations" (2112.04567) proposes an advanced optimization approach leveraging high-fidelity simulation to enhance the throughput of logistics enterprises' sorting centers. The central thesis is the application of an algorithm that optimizes the allocation of destinations and workforce to chutes while accounting for real-time forecasted demand and labor availability. The authors present a novel simulation-driven method to calibrate optimization parameters, delivering substantial improvements over traditional heuristic-driven sorting strategies.

Introduction

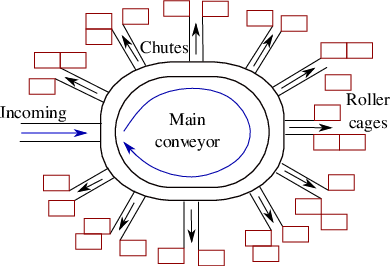

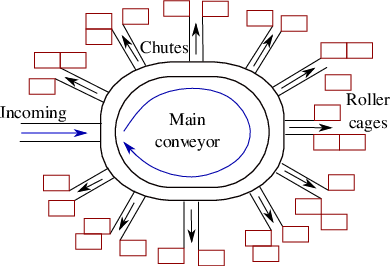

Sorting centers play a critical role in the operational infrastructure of parcel delivery logistics enterprises. These centers are tasked with efficiently sorting packages from incoming to outgoing destinations through systems of interconnected conveyor belts and chutes. They are sophisticated cyber-physical systems that integrate digital tracking and automated, sophisticated sorting algorithms (Figure 1).

Figure 1: Schematic plan of a sorting center, showing the main oval shaped conveyor belt and outgoing chutes. Each chute is associated with a fixed number of roller cages, and each roller cage may be assigned to at most one destination, though multiple roller cages can serve the same destination.

Current industry practices heavily rely on manual operations and basic heuristics for workload estimation and workforce assignment. However, these methods are insufficient given the demand volatility, especially post-pandemic, which has stressed existing infrastructures. To optimize the sorting center operations effectively, the paper emphasizes the necessity for an algorithm that adapitates to environmental stochasticity and integrates real-time insights to maximize performance within a given infrastructure setup.

Methodology

The central contribution of this study is the OPTSORT algorithm, a mixed-integer linear programming (MILP) approach used in combination with a digital twin-based simulation model for evaluating and improving sorting center operations.

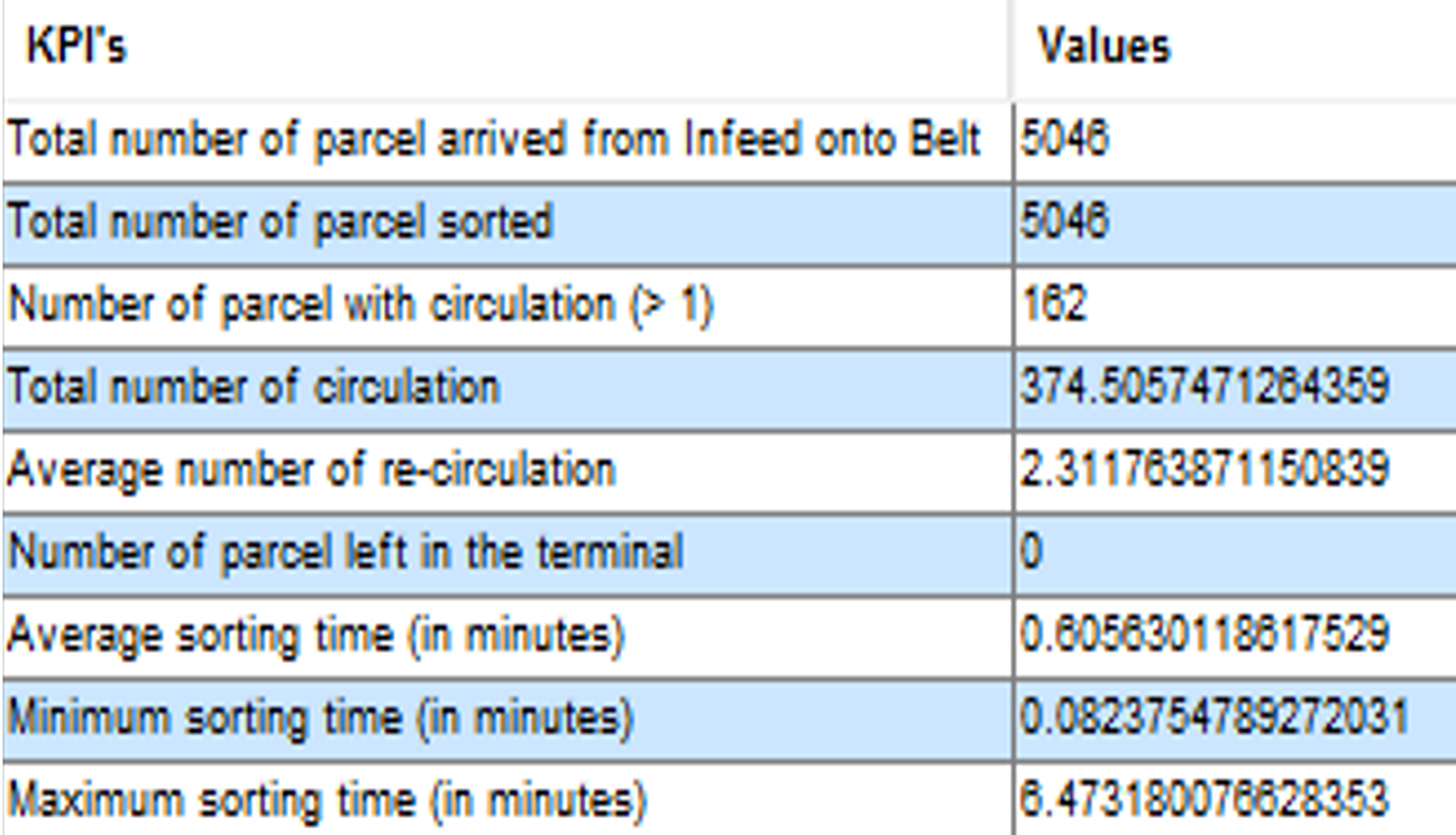

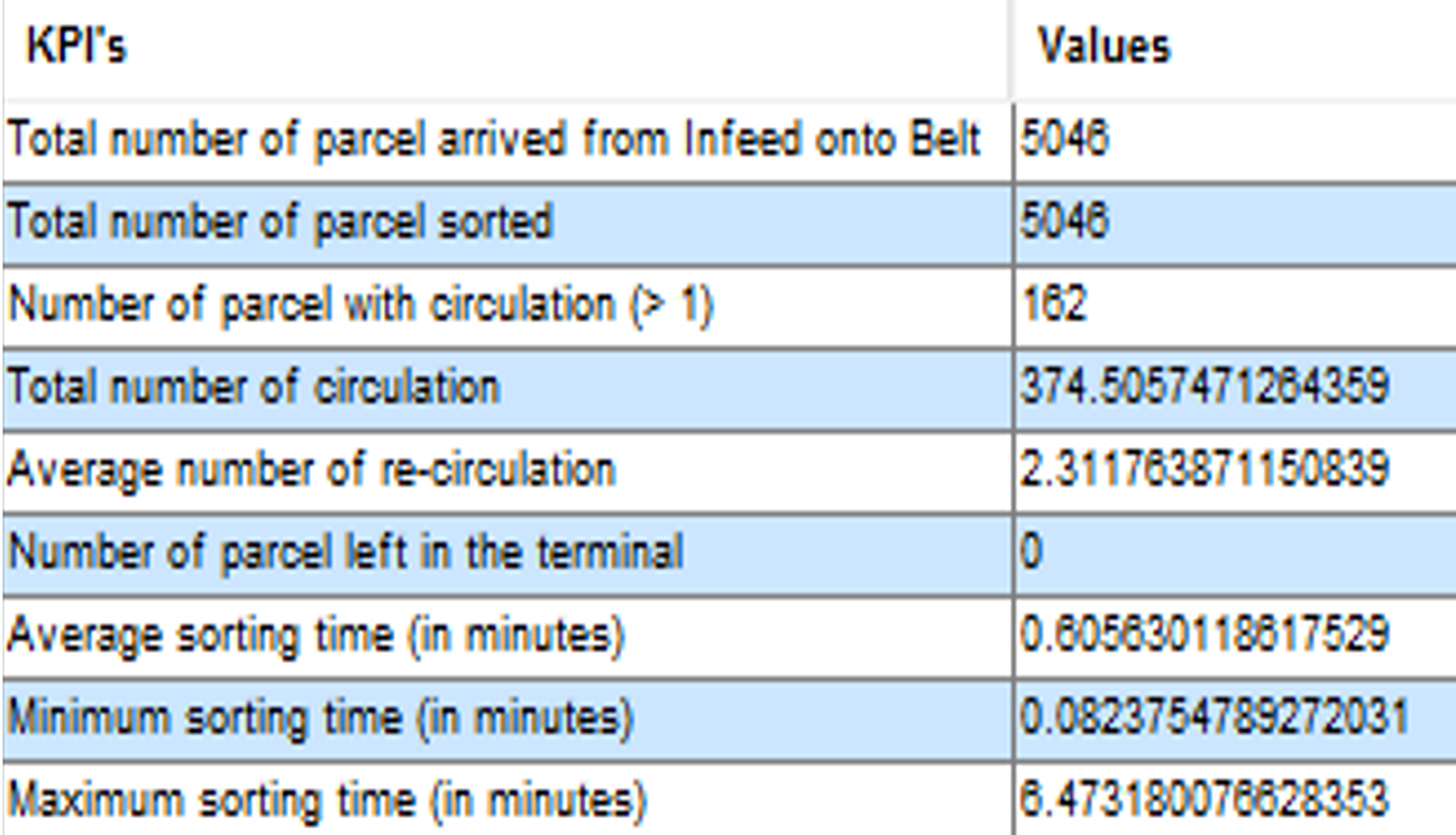

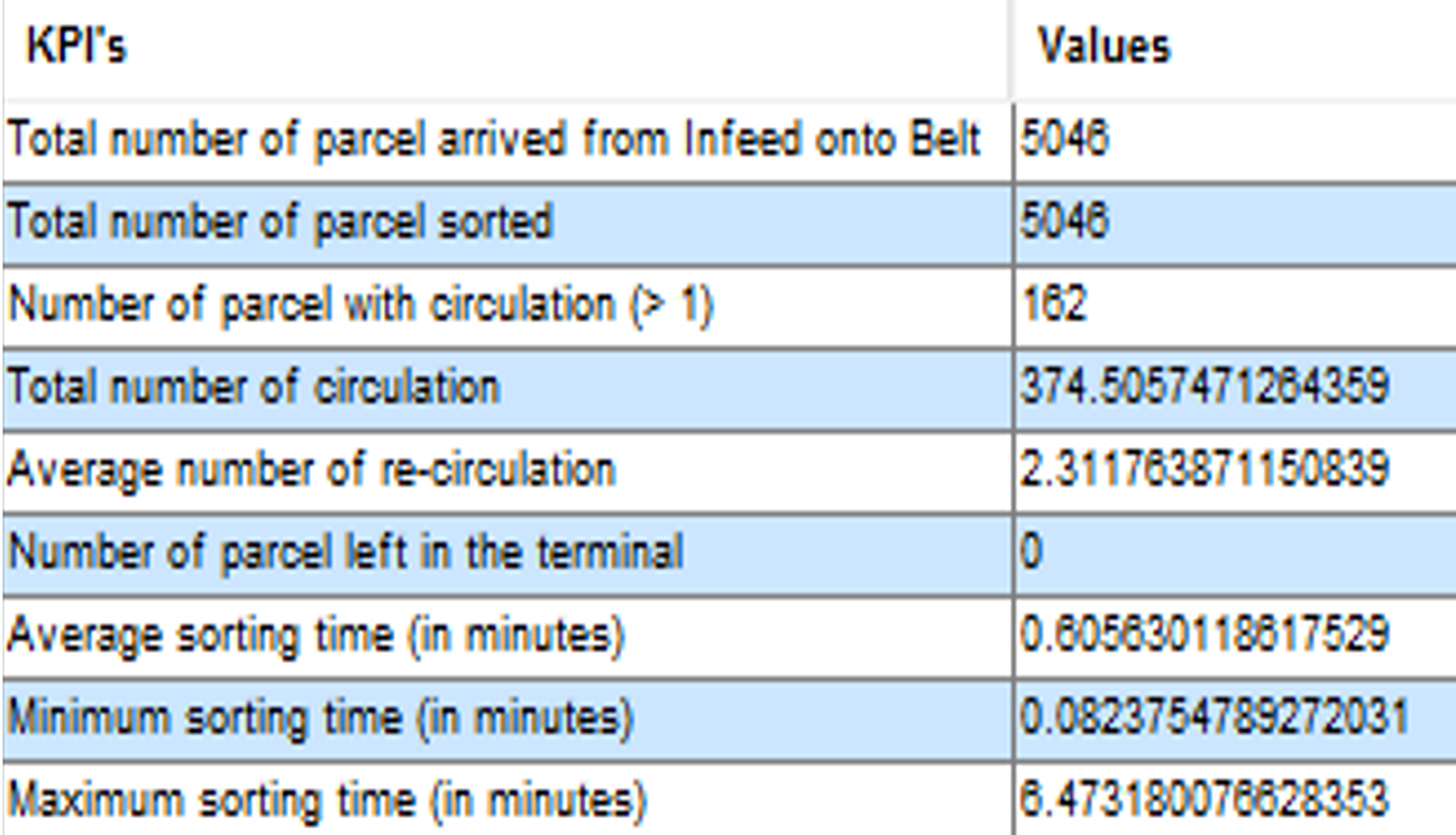

Figure 2: KPIs for GREEDY in unrestricted layout, captured in simulator interface.

Optimization Algorithm: OPTSORT

The problem is decomposed into distinct stages: planning and execution. Each stage has specific objectives targeted by the optimization procedure.

Planning Stage

The planning stage seeks to achieve an optimal mapping of destinations to chutes, based on demand forecasts and available workforce allocation. The MILP formulation maximizes the number of parcels processed, constrained by chute capacity, destination demands, and labor availability. It differentiates between spiral and direct chutes, where spiral chutes connect the conveyor belt to the loading area, allowing more flexible parcel allocations compared to direct chutes. The authors introduce additional binary variables Xij to represent the allocation of destinations to chutes, and Yij to indicate parcel processing at each chute, governed by a set of constraints to ensure operational efficiency and robustness to demand variability.

Figure 2: KPIs for GREEDY in unrestricted layout, captured in simulator interface.

Execution Stage

Once the planning is finalized and parcels begin to arrive, the execution phase commences. It involves a real-time allocation of parcels to designated chutes, respecting previously established allocation from the planning stage, while meeting operational constraints such as chute capacity and labor assignment.

Digital Twin for Simulation and Optimization

A high-fidelity digital twin of a sorting center was developed using an actor-based modeling paradigm. This model serves as a virtual representation of real-world sorting operations, capturing relevant entities, behavioral dynamics, uncertainties, and constraints of sorting systems.

The digital twin plays a crucial role in validating OPTSORT by simulating various demand scenarios, thereby providing feedback to refine and optimize the solution constraints further.

Results and Discussion

Experimental scenarios highlighted the efficacy of OPTSORT relative to traditional heuristic-based approaches such as GREEDY algorithms. In unrestricted layouts, OPTSORT processed 2% more parcels in high-load scenarios than the GREEDY method. One notable conclusion is the identification of too conservative constraints related to chute blockage, warranting a strategic relaxation of these constraints to enhance throughput while avoiding sub-optimal conservative decision-making (Figure 2).

In restricted layouts, the performance gains were slightly diminished, albeit OPTSORT maintained a zero recirculation rate, a key contributor to the robustness of operations. Integrating workforce allocation into the optimization framework further enhanced throughput efficiency, demonstrating the holistic utility of the proposed methodology. The continued feedback loop using the digital twin led to iterative optimization improvements, emphasizing adaptive operational strategies to counter demand variation and uncertainties such as operator efficiency and equipment reliability.

Conclusion

The proposed solution exemplifies the effectiveness of a simulation-driven optimization approach to address the needs of modern sorting center operations. Through the OPTSORT approach combined with a digital twin environment, the study successfully demonstrates an adaptable framework that increases the throughput of parcel sorting centers. While the current scope focuses mainly on sorting center operations and specific constraints such as labor allocations and scenario-driven simulations, future research is expected to expand and integrate more complex real-world constraints and explore further potential through advanced heuristic approaches, perhaps incorporating reinforcement learning for sequential decision-making in logistics operations.