- The paper introduces a deep belief network-based multi-state framework to diagnose tool health and forecast wear for improved maintenance.

- It integrates an evolutionary cost-sensitive DBN for accurate fault diagnosis with unsupervised feature learning for robust wear estimation.

- Experimental results on gun drilling data demonstrate enhanced precision, lower RMSE, and superior adaptability across tool wear states.

Tool Condition Monitoring (TCM) constitutes a pivotal aspect of modern manufacturing processes, significantly enhancing product precision while minimizing downtime and maintenance expenses. This paper introduces a Multi-State Diagnosis and Prognosis (MDP) framework for TCM utilizing a Deep Belief Network-based Multi-State (DBNMS) approach. The proposed framework distinguishes itself by its ability to automatically learn feature representations, thereby ensuring superior accuracy and robustness in tool wear and state estimation tasks.

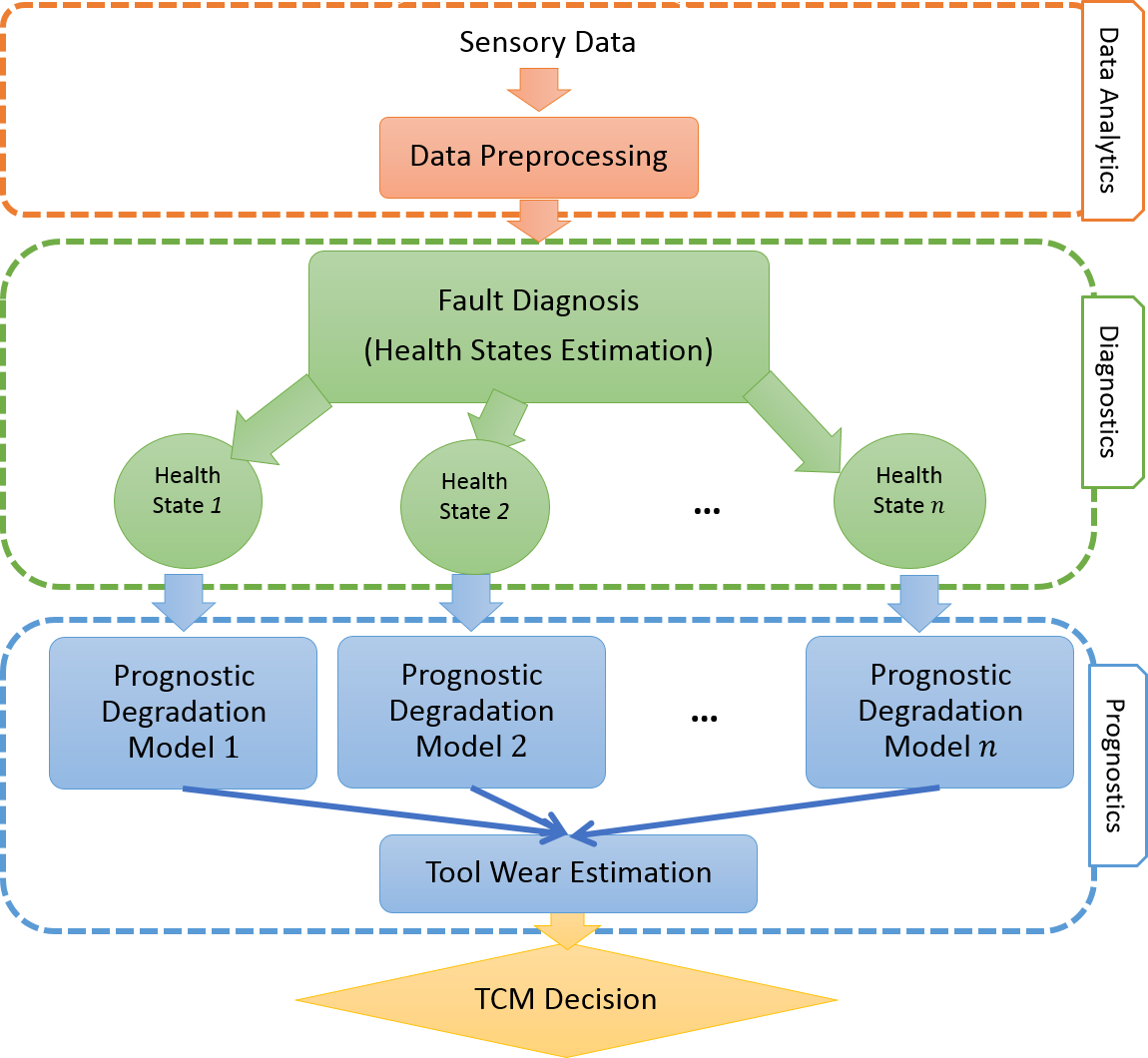

Multi-State Diagnosis and Prognosis Framework

The MDP framework is a comprehensive approach integrating both diagnostic and prognostic components for tool condition monitoring.

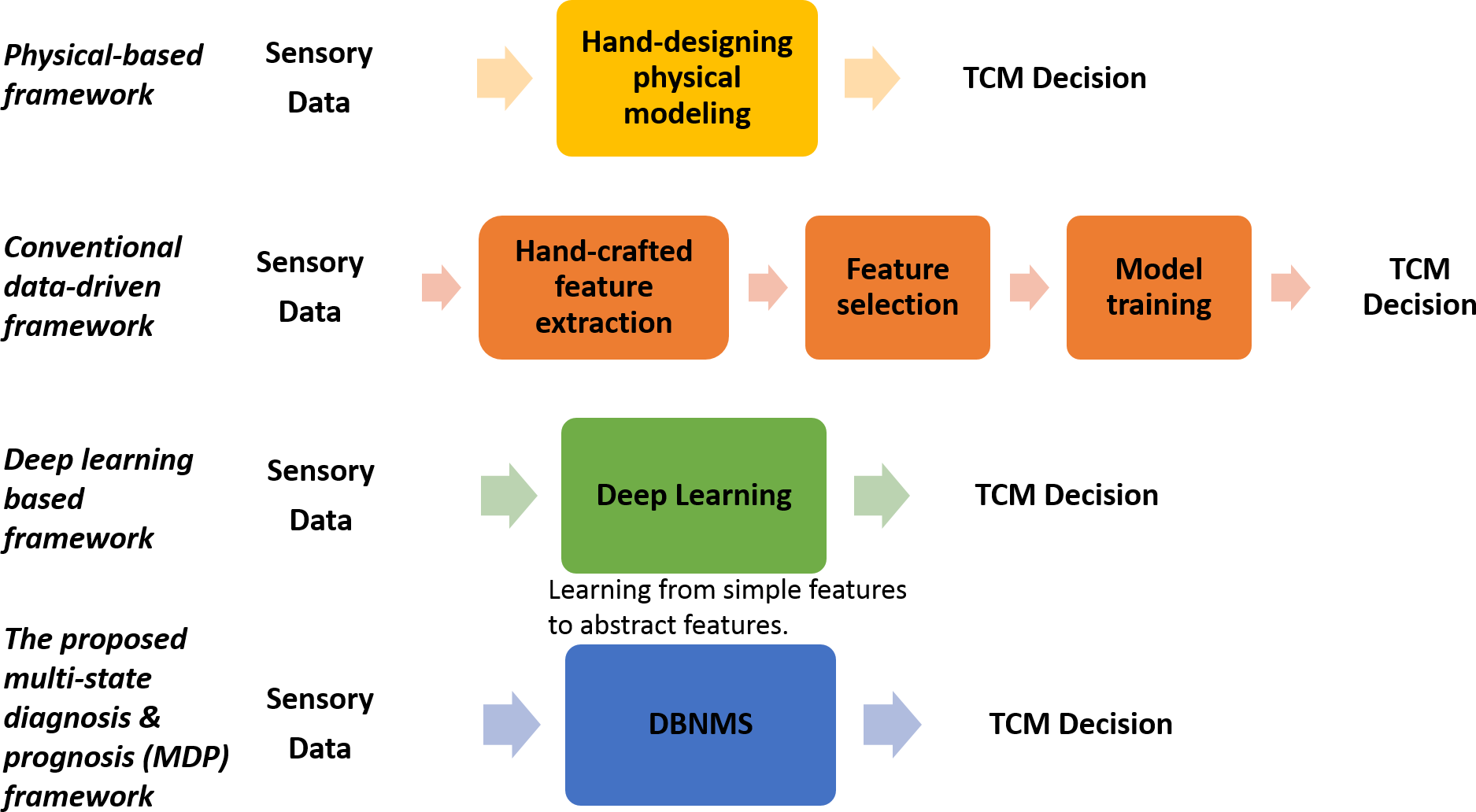

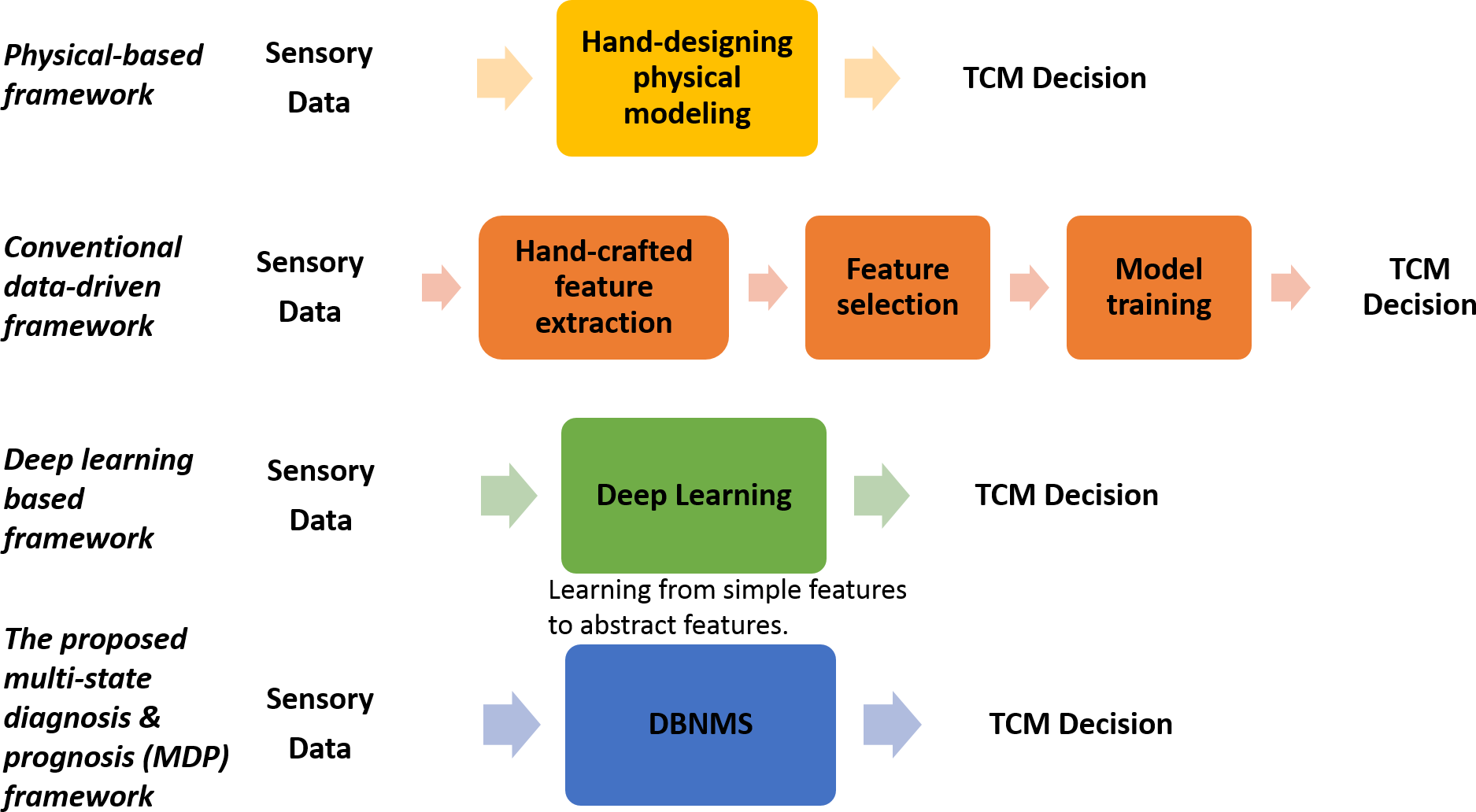

Comparison with Other Frameworks

The MDP framework is juxtaposed with physical-based frameworks, conventional data-driven frameworks, and deep learning-based frameworks.

Figure 2: Comparison of four different frameworks, i.e., physical-based, conventional data-driven based, deep learning based and MDP. Round boxes denote algorithm/computing modules.

This framework demonstrates significant improvements in predictive accuracy and adaptability to various tool states compared to its counterparts. It automatically generates feature representations without the need for human-crafted features, allowing seamless adaptation to changing operational conditions.

Experimental Setup and Dataset

The efficacy of the proposed DBNMS framework is validated using a real-world dataset from gun drilling experiments. The dataset encompasses diverse sensor data including force, torque, and vibration, gathered in a controlled environment.

Figure 3: Illustration of the experimental setup of gun drilling experiments with force, torque and vibration sensors. The force and torque sensor is placed on end of the tool. The four accelerometers (vibration sensors) are placed on top of the workpiece, then connected to a DAQ card. Finally, a laptop is used for data collection and data logging.

Figure 4: Illustration of the front (on the left) and side (on the right) views of the workpiece and sensor layouts in gun drilling experiment. Note that the z axis is the same with gun drilling direction.

Implementation and Results

The experiments reveal that the ECS-DBN and DBNMS methods excel at both tool state classification and tool wear estimation tasks. ECS-DBN particularly shows high efficacy in handling class imbalance issues, demonstrating superior diagnostic precision.

- Diagnostics Performance: The ECS-DBN achieves higher G-mean and F1-scores compared to other classifiers, indicating a balanced performance across various tool wear states.

- Prognostics Performance: The DBNMS approach yields remarkable precision in wear prediction, achieving low RMSE and high R2Score metrics. The framework also demonstrates superior generalization ability across different operating conditions.

Conclusion

The proposed MDP framework marks an advancement in TCM, integrating seamless multi-state diagnosis and prognostics to improve tool condition monitoring. Future work will explore the incorporation of more sophisticated deep learning architectures to further enhance predictive capabilities.

This framework stands as a robust, scalable solution catering to varying tool wear conditions, offering substantial benefits for industrial applications in terms of predictive maintenance and reliability.