- The paper presents a novel robotic mechanism inspired by the Jacob’s Ladder toy, using kinematic singularity to achieve obstacle traversal.

- It introduces a flipping gait through sequential actuation of rigid segments connected by cables, validated by geometric and dynamic modeling.

- Experimental results demonstrate that multi-robot collaboration enhances terrain adaptability, despite higher energy costs compared to wheeled locomotion.

FlipWalker: Jacob's Ladder Toy-Inspired Robot for Locomotion Across Diverse, Complex Terrain

Introduction and Motivation

The FlipWalker system presents a novel approach to robotic locomotion, leveraging the kinematic singularity and axis-switching mechanism of the Jacob's Ladder toy to traverse complex terrains. Unlike conventional wheeled or tracked robots, FlipWalker utilizes sequential flipping of interconnected rigid segments, joined by flexible cables, to achieve both forward displacement and obstacle traversal. This design is motivated by the need for adaptable, low-cost robotic platforms capable of operating in environments where traditional mobility solutions are inadequate, such as biodiversity surveying and disaster response.

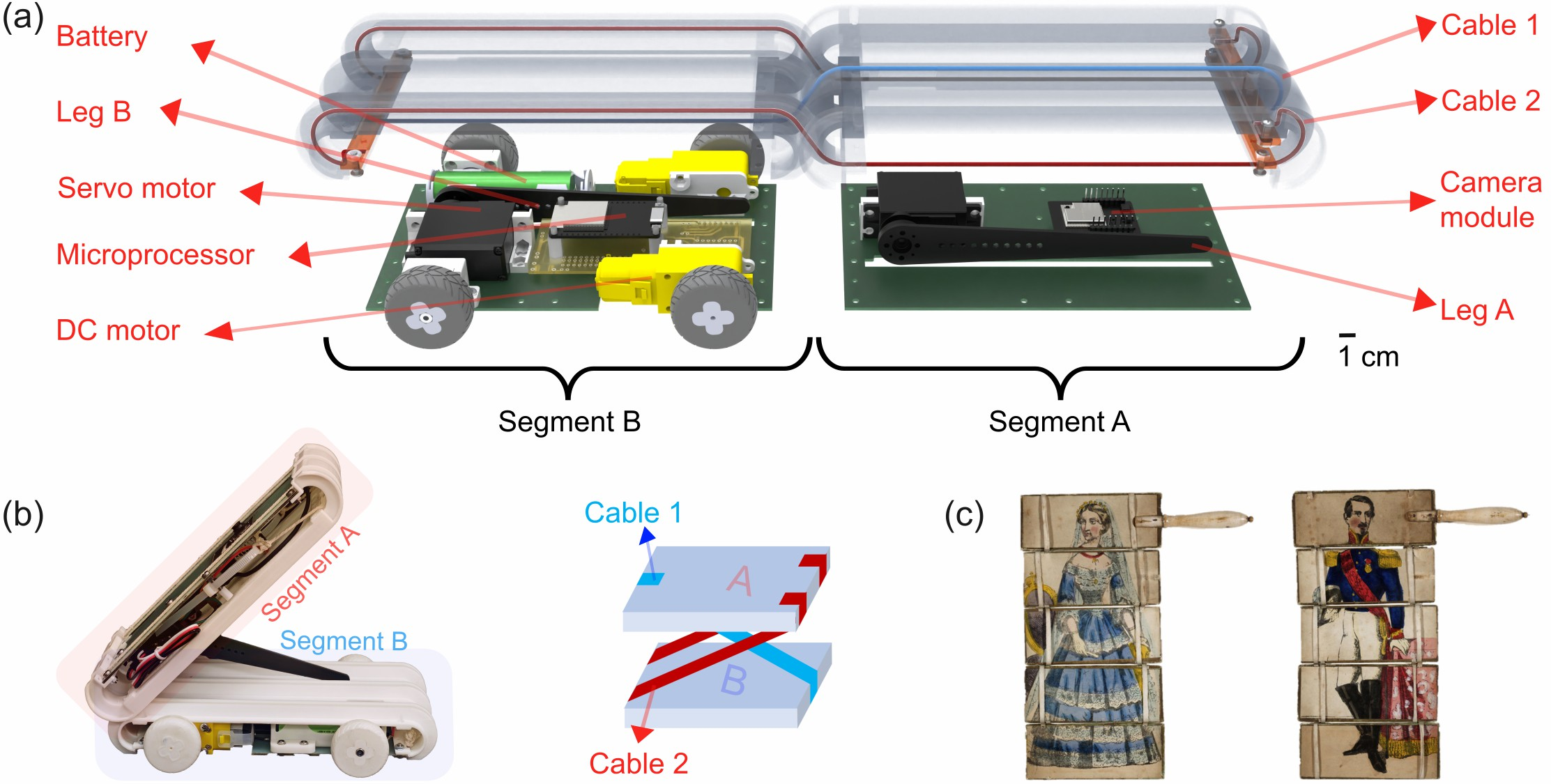

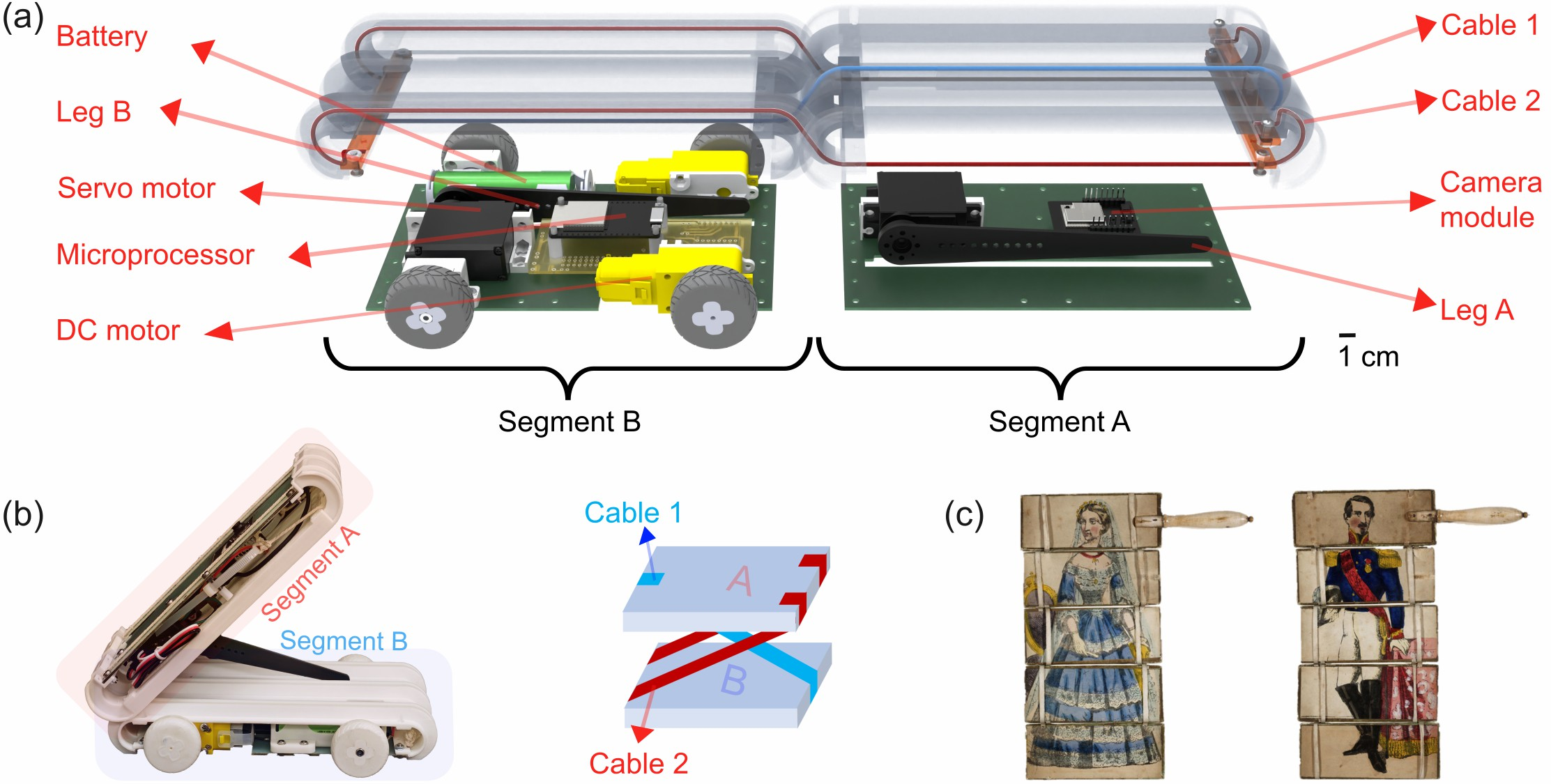

Figure 1: FlipWalker’s mechanism borrows from the Jacob’s Ladder toy, enabling axis switching via cable-linked rigid segments.

Mechanical Design and Locomotion Principle

The FlipWalker prototype consists of two rigid body segments connected by three flexible, inelastic cables. The cable configuration induces a kinematic singularity when the segments are parallel, allowing seamless switching of the rotational axis without active clutching. Each segment is equipped with a single-degree-of-freedom (DoF) rotational leg, actuated by a servo motor, which delivers the necessary ground reaction force for flipping. The robot supports dual-mode operation: wheeled locomotion for flat terrain and flipping for obstacle negotiation.

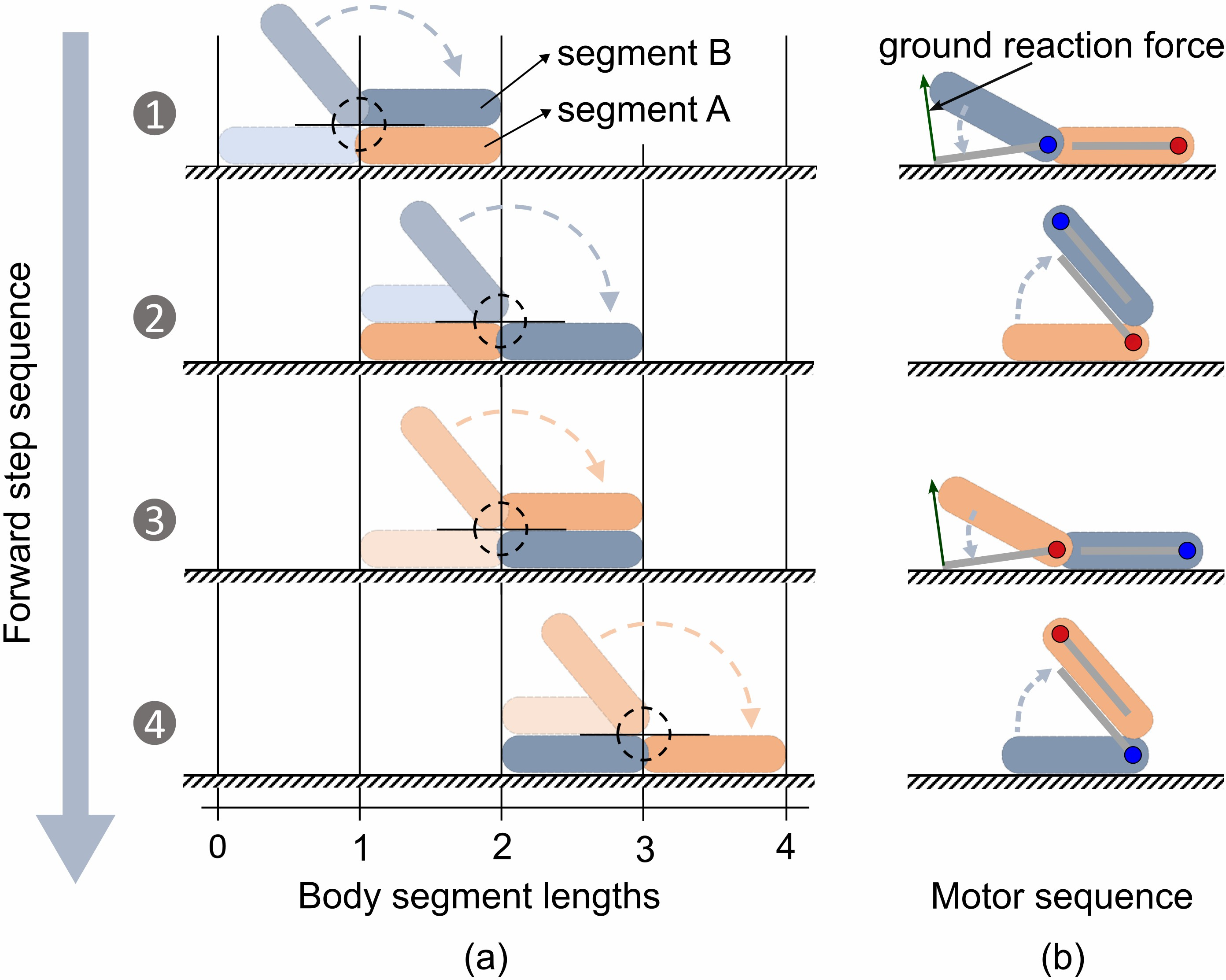

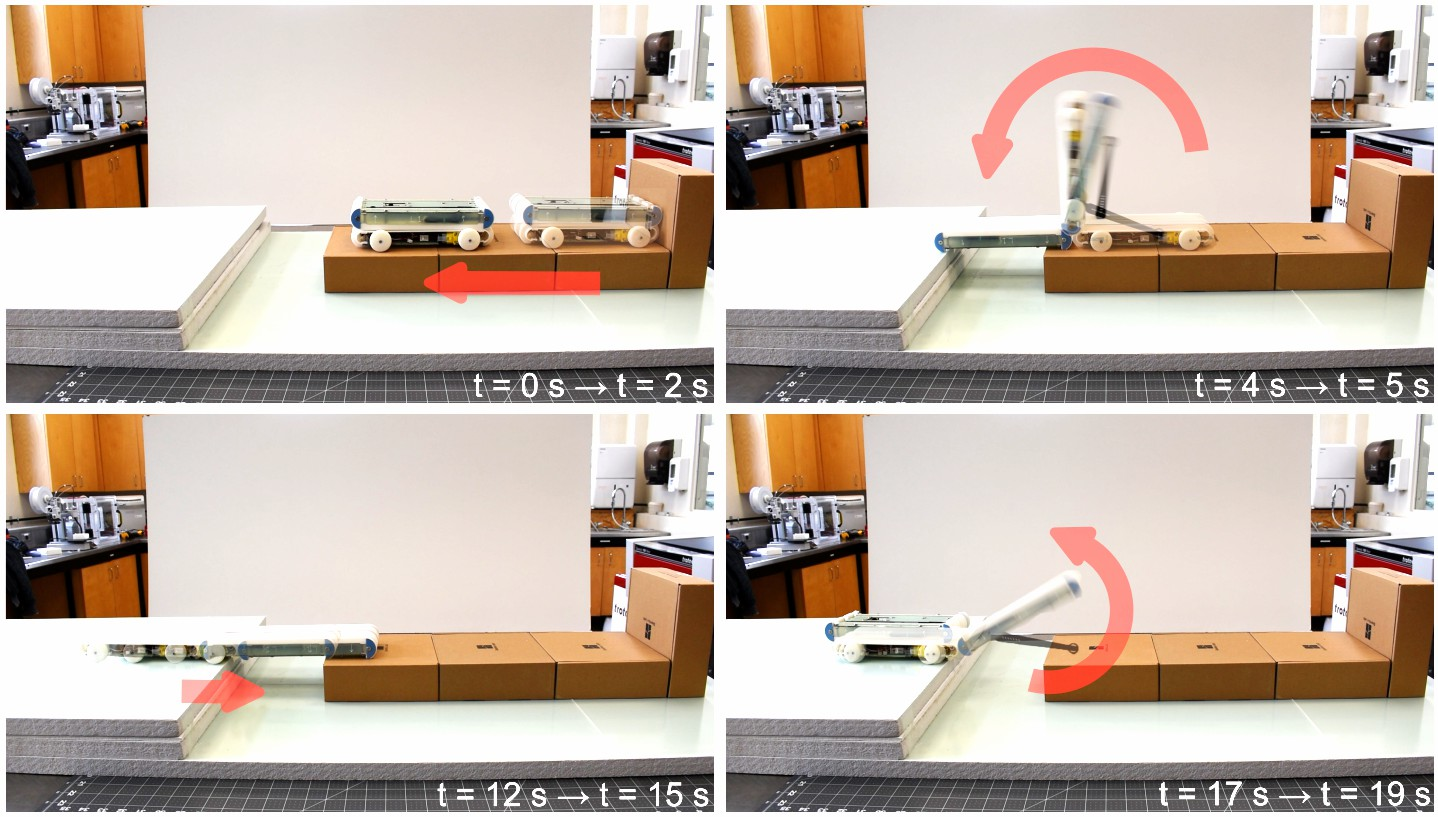

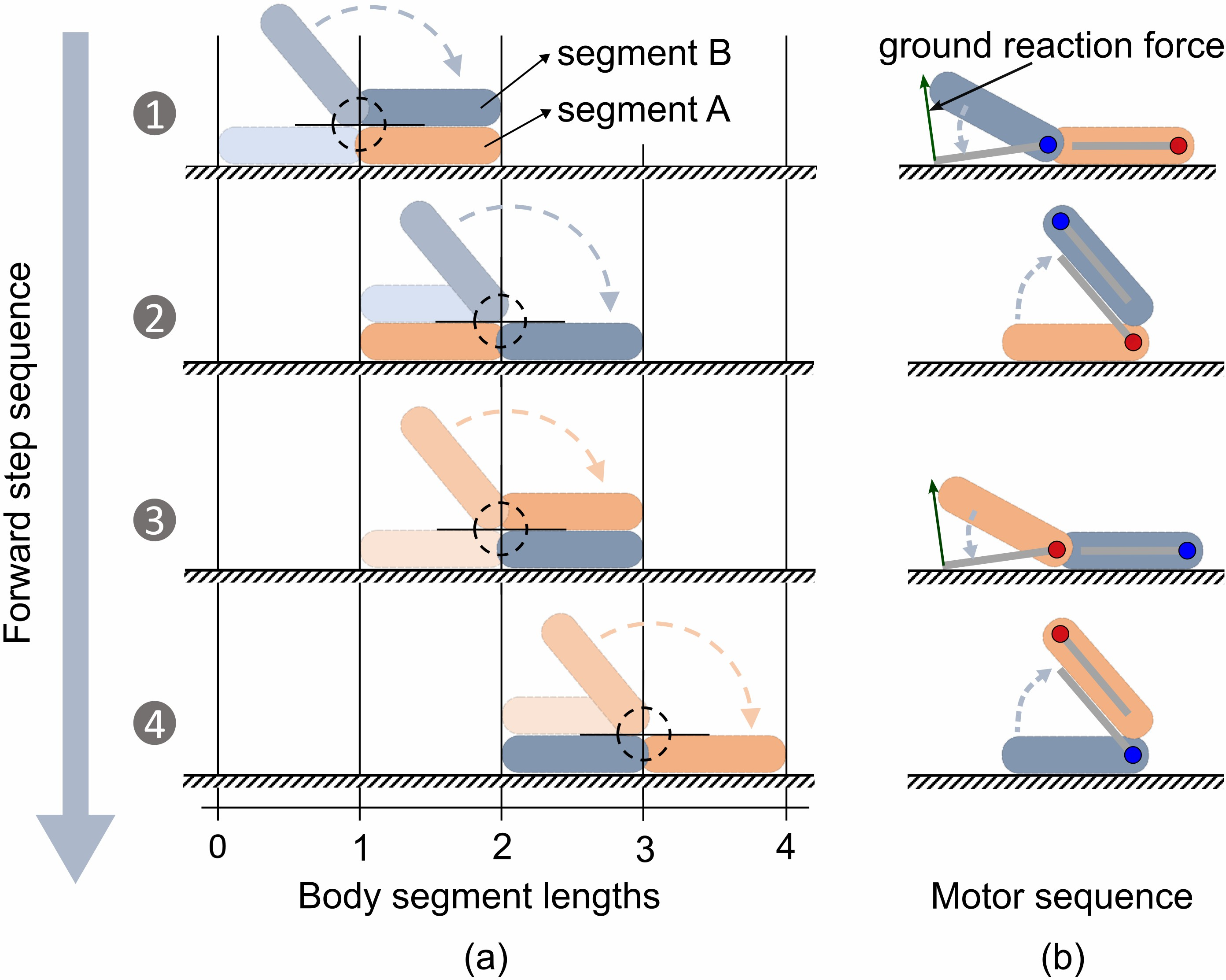

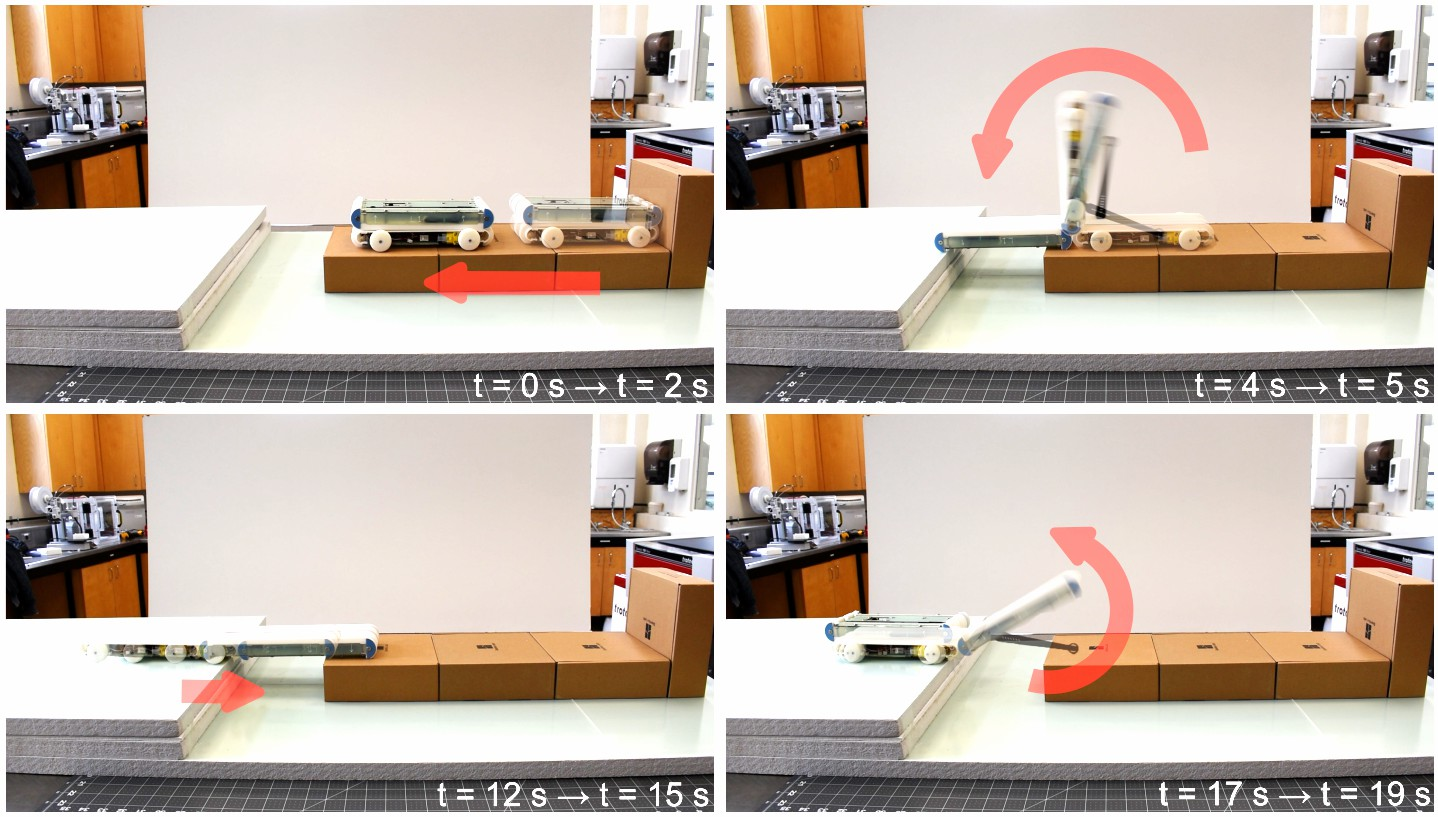

Figure 2: The flip-walking cycle comprises four discrete steps, each driven by a motor-actuated leg applying ground reaction force for flipping.

The flipping sequence is cyclic and consists of four steps, alternating the active segment and the direction of leg actuation. This ensures that at least one segment maintains ground contact throughout the process, enhancing stability and terrain adaptability compared to ballistic flip robots.

Analytical Modeling and Design Optimization

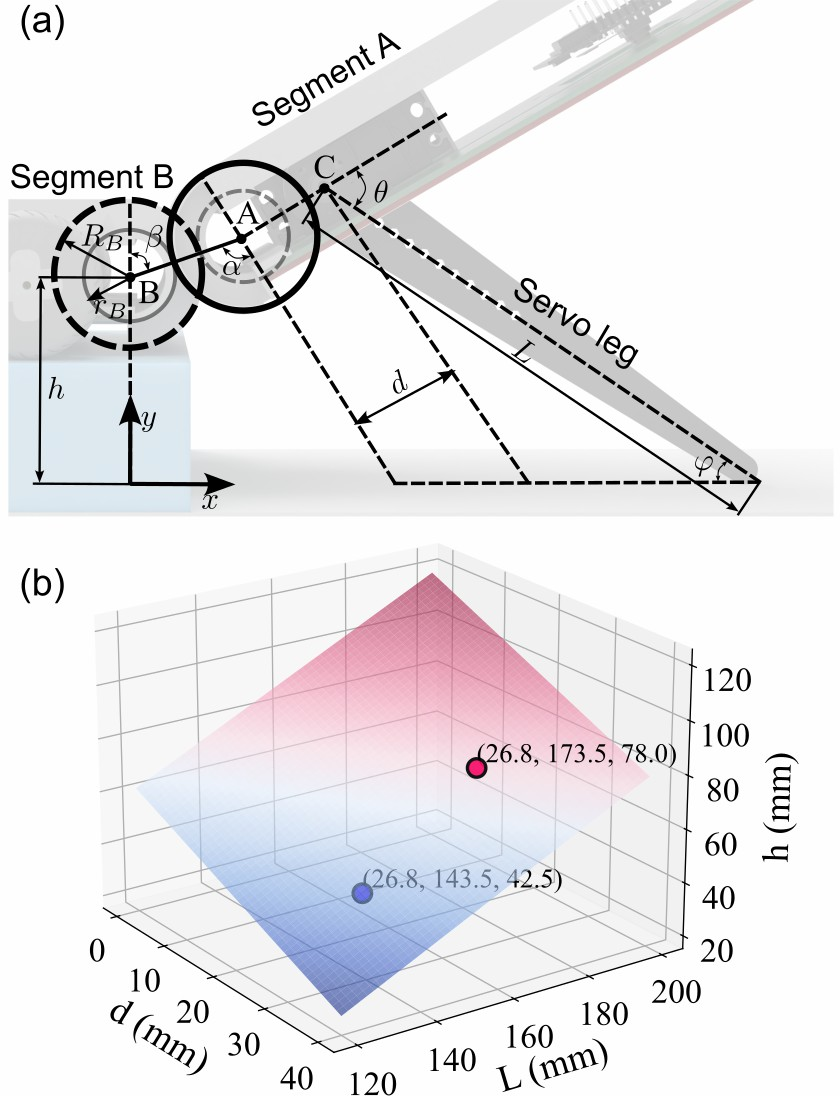

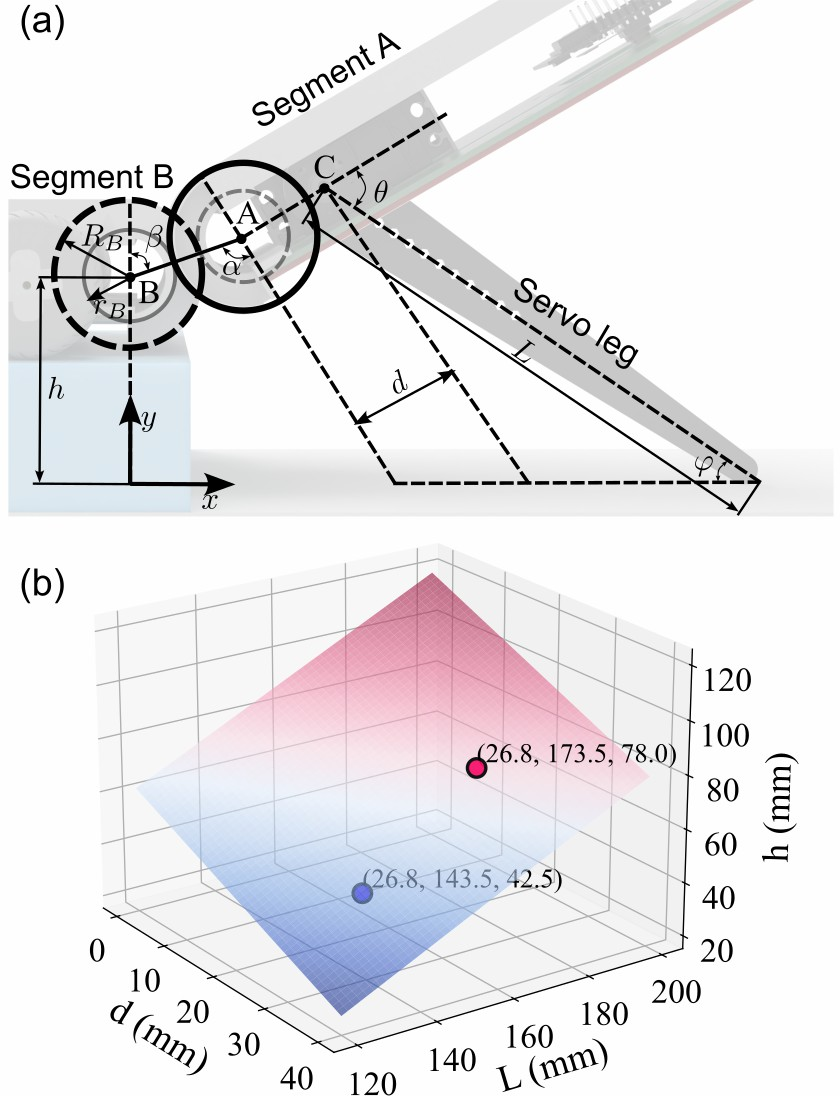

A geometric and kinematic model is formulated to relate critical design parameters—leg length (L), servo mounting offset (d), and actuation range (θmax)—to obstacle clearance and flipping dynamics. The model accounts for the moving instantaneous center of rotation and the coupling between leg geometry and achievable climbing height (h):

h=Lsin(2α−θ)+32cosα+dsin(2α)

Experimental validation with two prototypes (Model S and Model L) demonstrates that increased leg length and tip radius improve climbing performance, with Model L exceeding static predictions due to unmodeled kinetic energy contributions.

Figure 3: Influence of leg length (L) and offset (d) on maximum climbing height (h); Model L outperforms Model S.

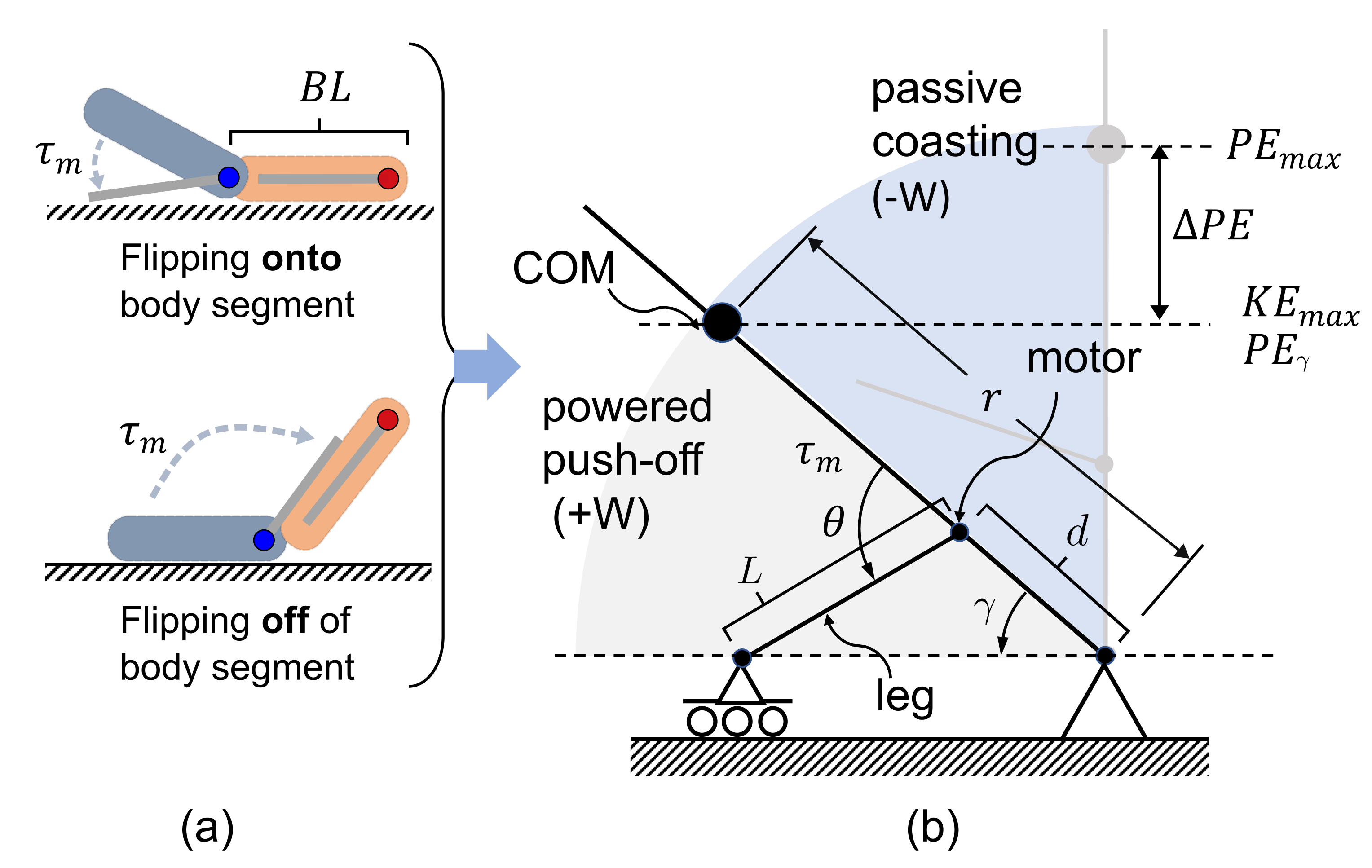

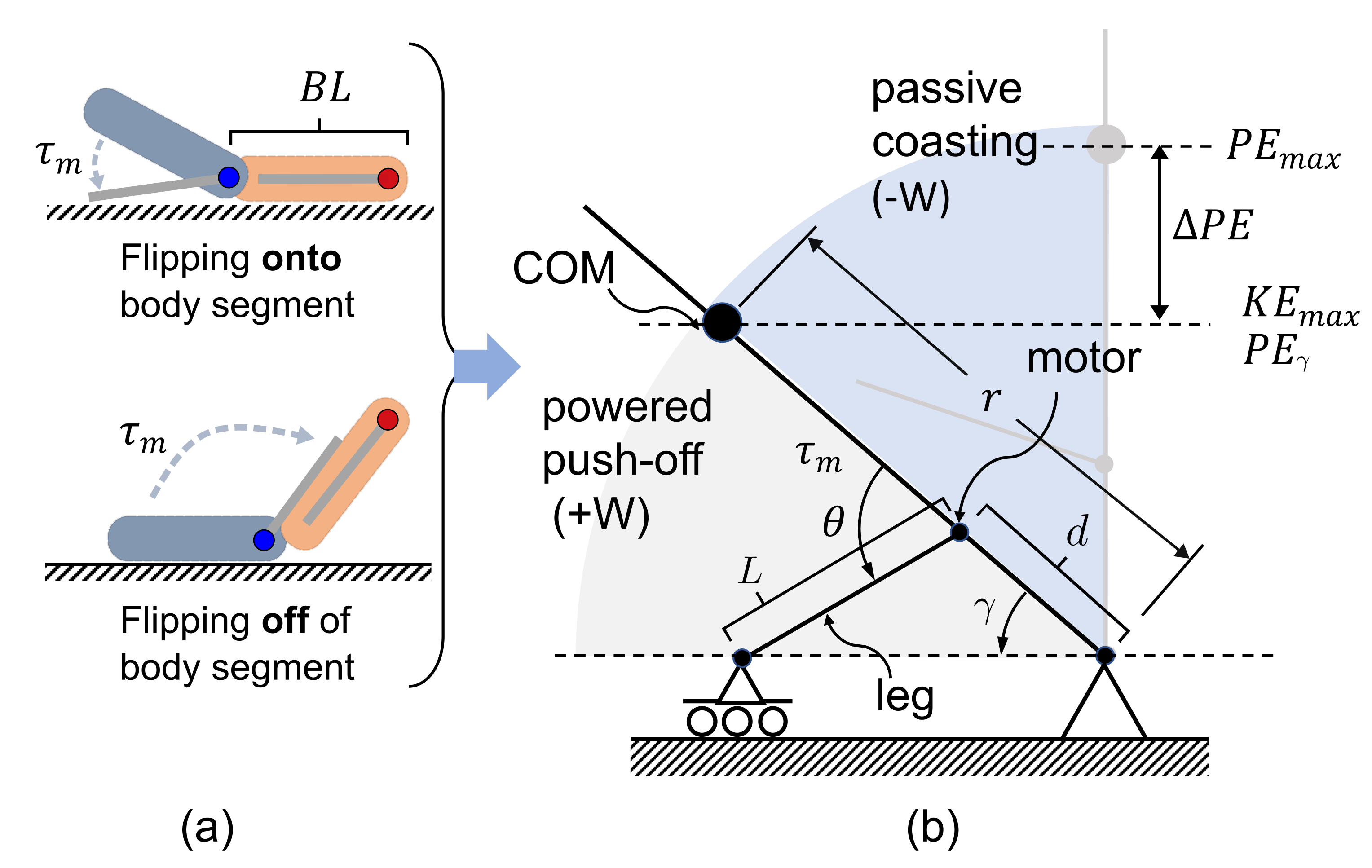

The dynamic model, based on the Lagrangian formalism, quantifies the minimum motor torque required for successful flipping:

τmθmax≥mgr(1−sinγ)

This provides a direct link between actuator selection and terrain capability, enabling informed design trade-offs.

Figure 4: Flipping mechanics are governed by physical design parameters, with actuation dynamics approximated by a simplified model.

Experimental Evaluation: Terrain Adaptability and Multi-Robot Collaboration

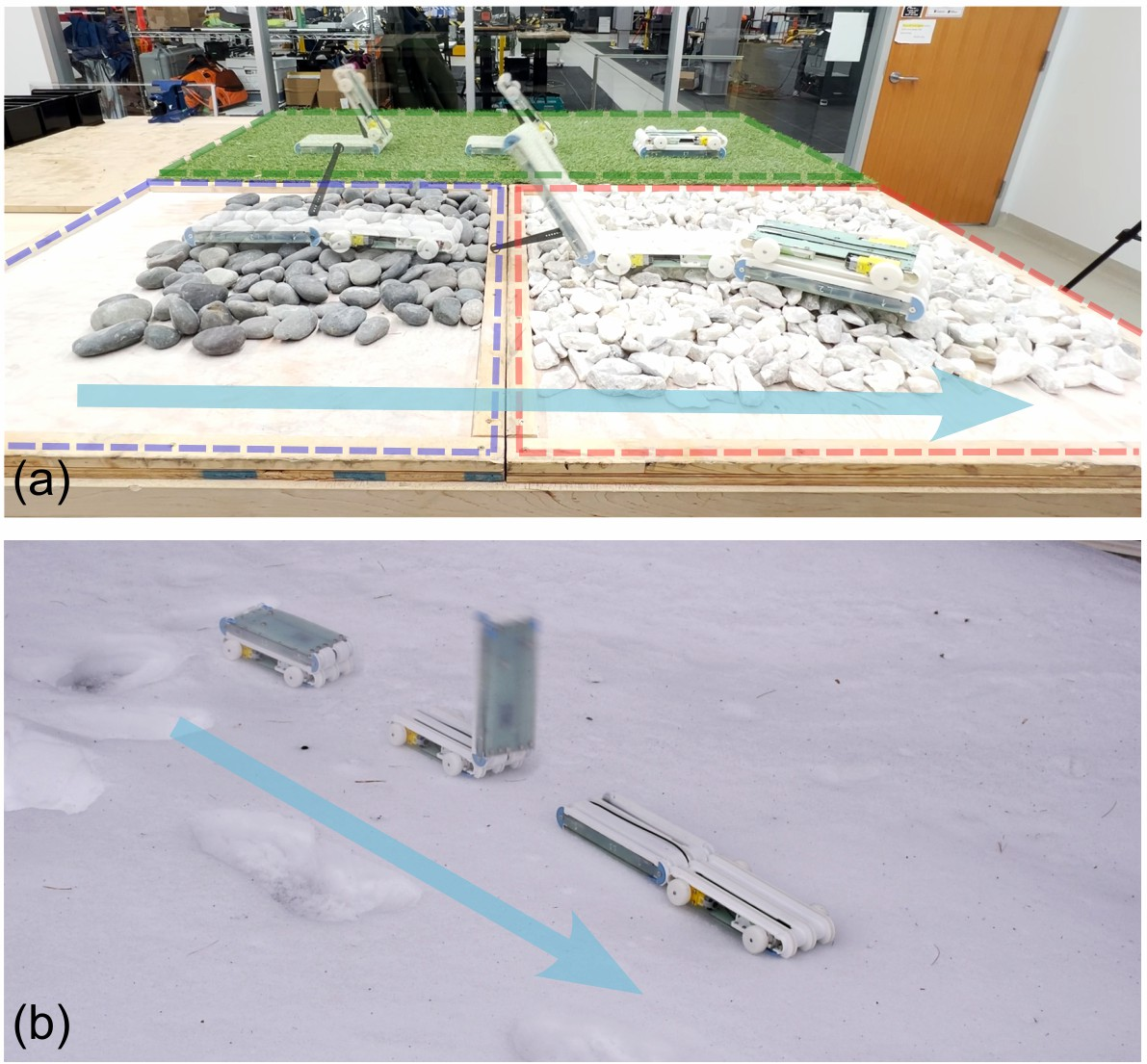

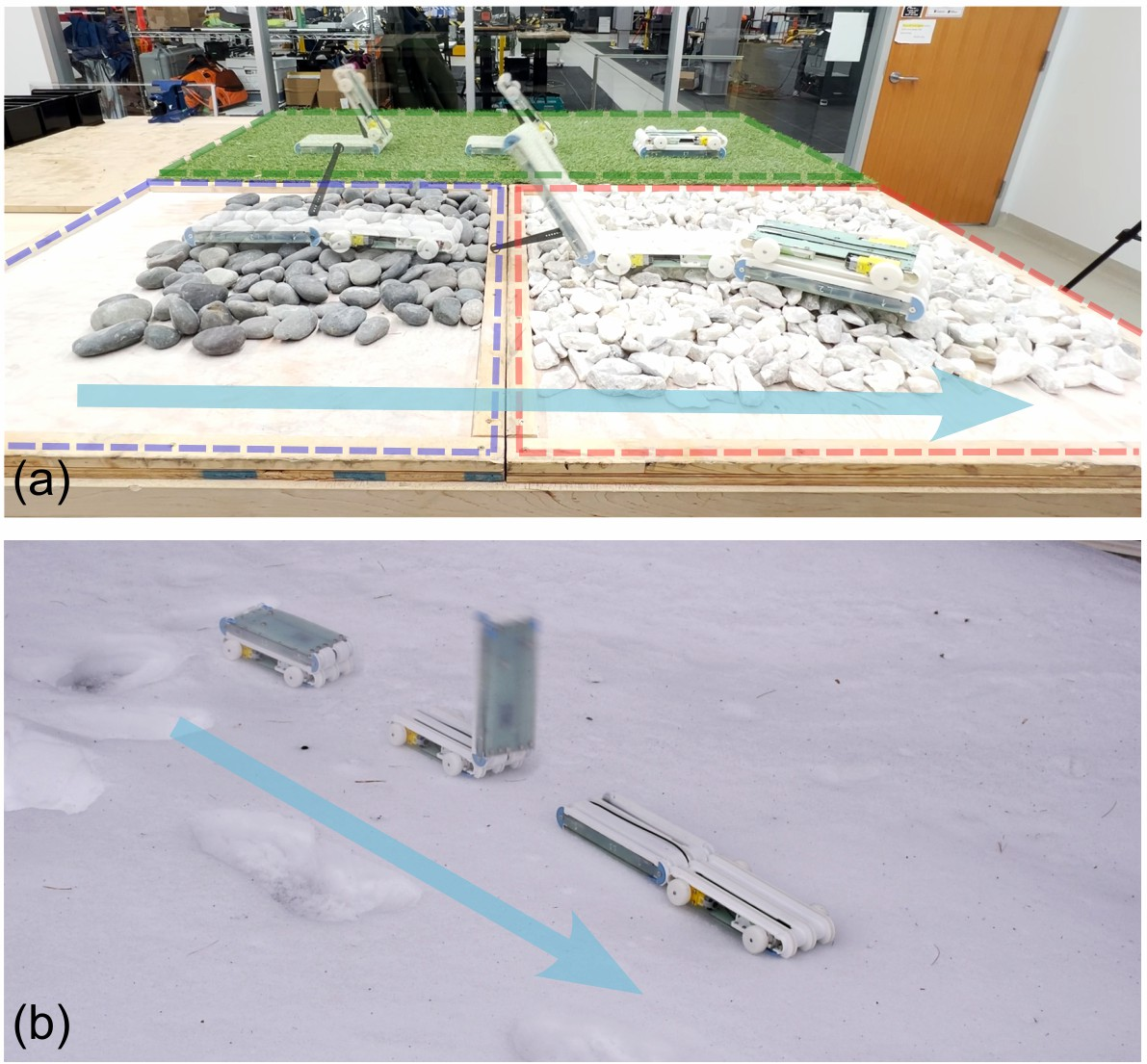

FlipWalker’s flipping mechanism enables traversal of gaps wider than its wheelbase and operation on surfaces where wheeled robots fail, including artificial grass, river rocks, marble stones, and snow. The addition of a magnetic flexible plate increases ground contact area, improving performance on soft substrates.

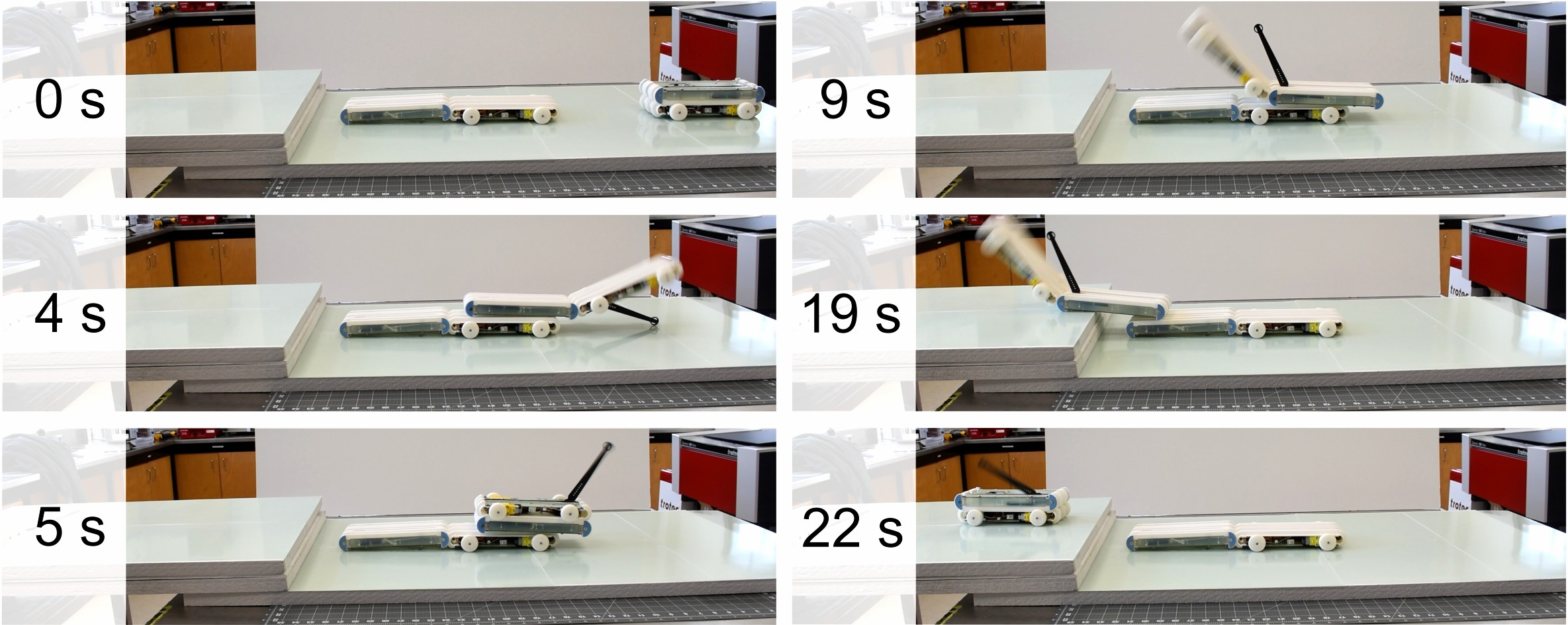

Figure 5: FlipWalker bridges a gap using its flipping mechanism, demonstrating terrain adaptability.

Figure 6: Experimental trials on diverse terrains highlight FlipWalker’s superiority over wheeled systems in irregular environments.

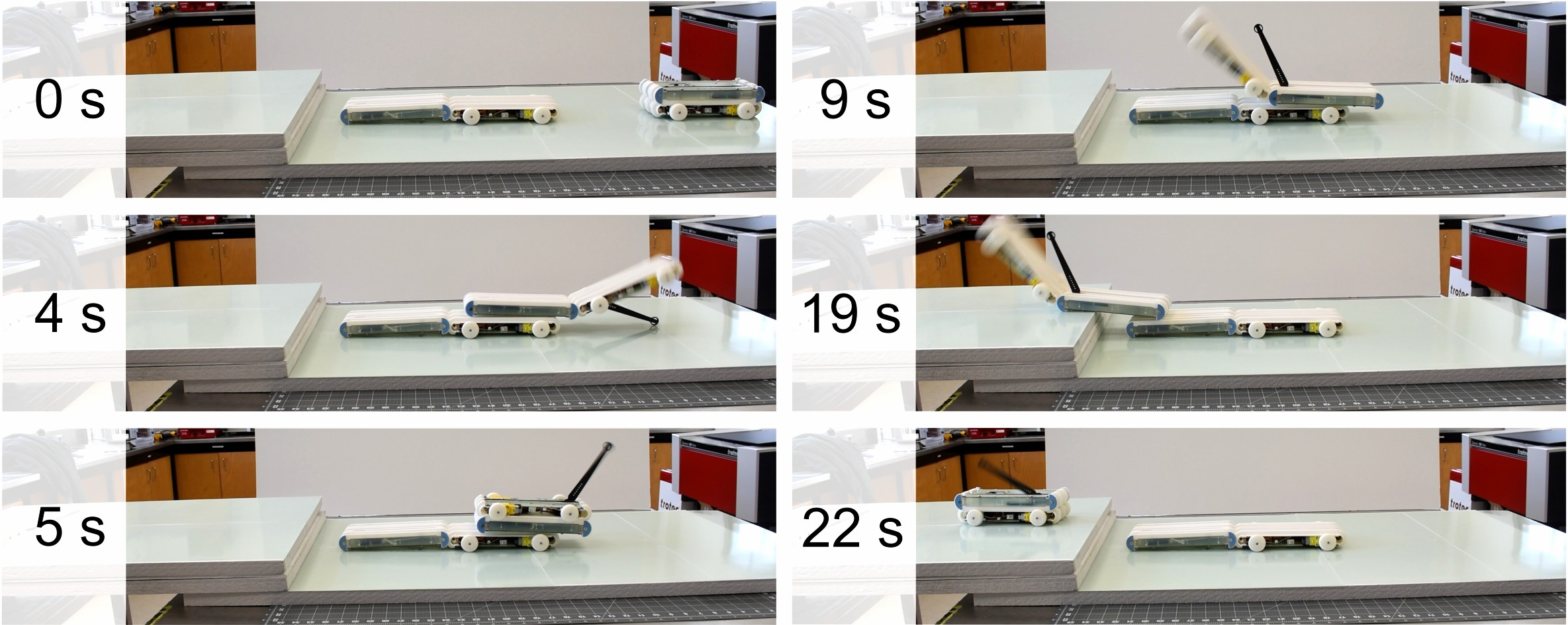

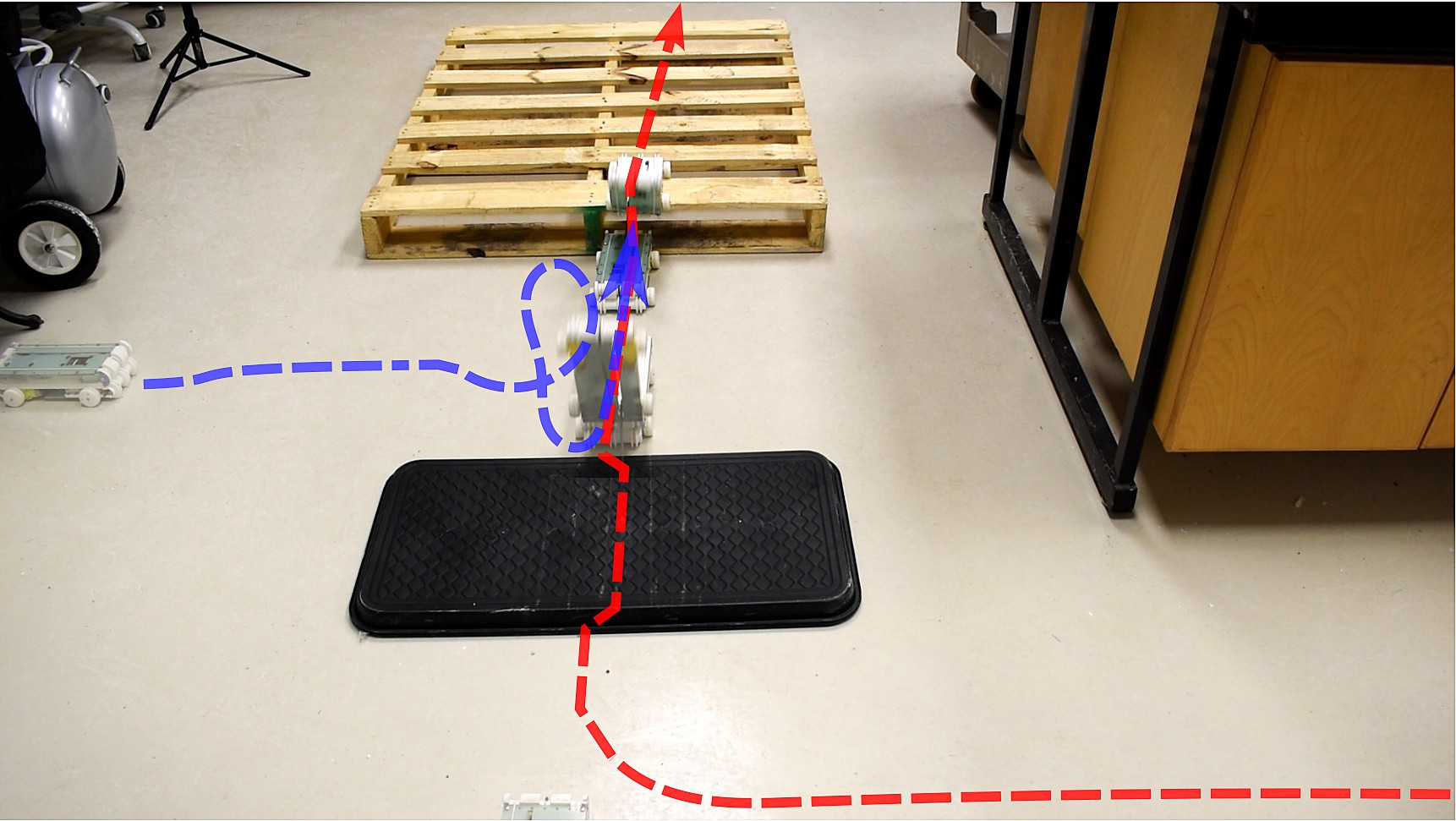

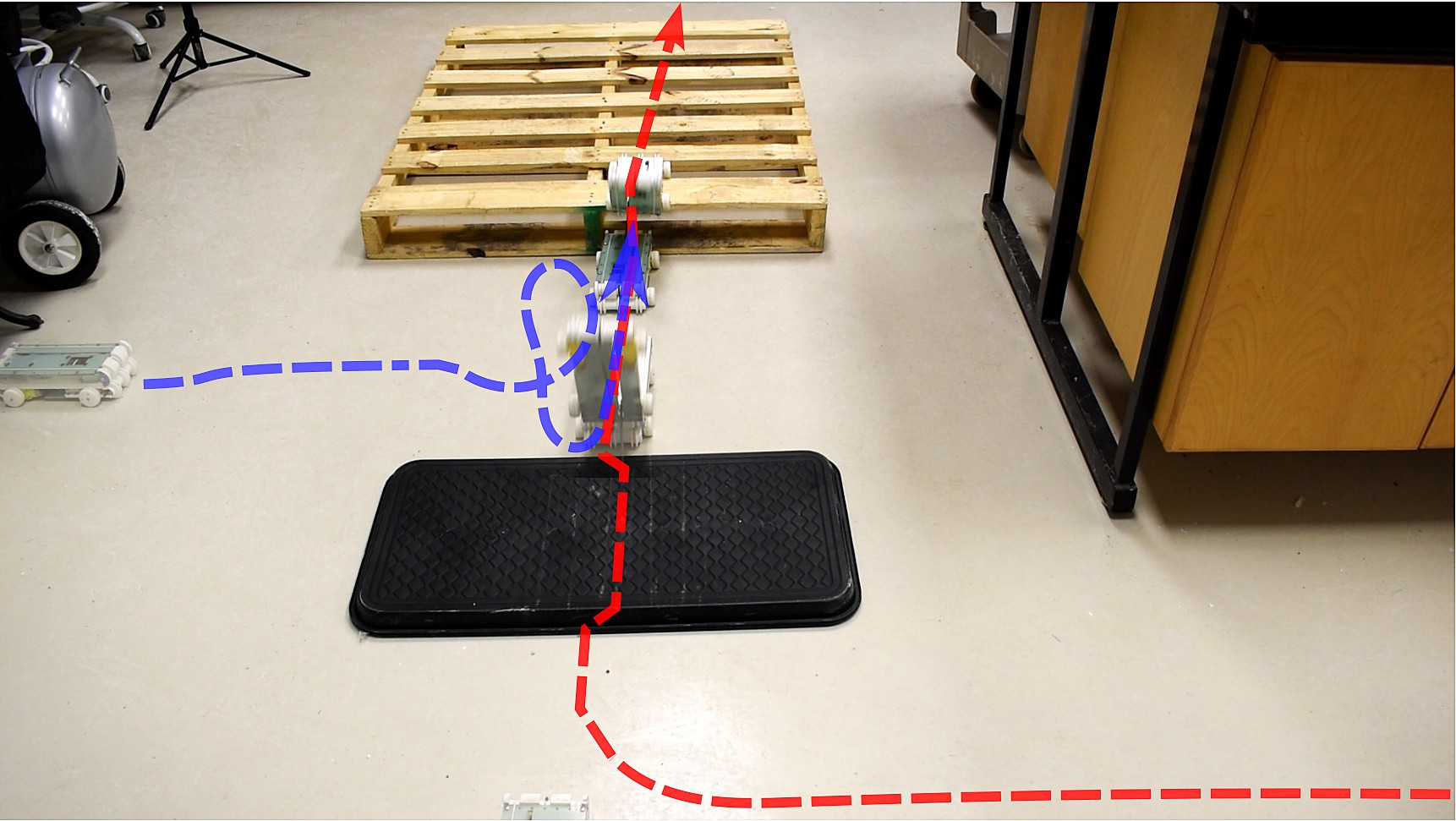

Multi-robot collaboration is demonstrated, with two FlipWalkers coordinating their flipping actions to climb elevated platforms and overcome obstacles exceeding the capability of a single unit. The robots dynamically reconfigure their roles as ‘assistant’ and ‘climber’, leveraging discrete push-off events rather than continuous traction.

Figure 7: Two FlipWalkers climb a stage cooperatively, sharing leverage for obstacle negotiation.

Figure 8: Collaborative navigation over multi-level platforms, with robots realigning to overcome height differentials.

Energy Efficiency and Cost of Transport

Power consumption measurements reveal a cost of transport (CoT) of 16.98 in flipping mode and 3.27 in wheeled mode for the 0.77 kg prototype. While the flipping gait incurs higher energy expenditure, it enables mobility in scenarios inaccessible to rolling or driving. Comparative analysis with other field robots shows that FlipWalker’s CoT is within the expected range for sub-kilogram platforms, with energy efficiency highly dependent on locomotion mode and terrain.

Implications and Future Directions

The FlipWalker concept introduces a new class of underactuated, singularity-driven robots capable of robust locomotion across heterogeneous terrains. The mechanical simplicity and modularity of the design facilitate scalability and potential deployment in swarm configurations. The analytical framework enables systematic optimization of design parameters for specific operational requirements.

Future work should address energy losses due to terrain interaction, friction, and impact, as well as the integration of inertial sensors for autonomous control and localization. Alternative actuation schemes, such as solenoids or soft actuators, may further enhance efficiency and adaptability. Autonomous multi-robot coordination strategies could extend FlipWalker’s utility in collaborative tasks and real-world field applications.

Conclusion

FlipWalker demonstrates that kinematic singularity and axis-switching mechanisms, inspired by the Jacob’s Ladder toy, can be effectively harnessed for robotic locomotion in complex environments. The system achieves stable, adaptive movement through sequential flipping, supported by a rigorous analytical model and validated by experimental trials. While the flipping gait is less energy-efficient than wheeled locomotion, it offers unique advantages in terrain adaptability and collaborative operation. The platform’s simplicity, scalability, and analytical tractability position it as a promising candidate for future research in field robotics, swarm systems, and autonomous exploration.