Effect Identification and Unit Categorization in the Multi-Score Regression Discontinuity Design with Application to LED Manufacturing (2508.15692v1)

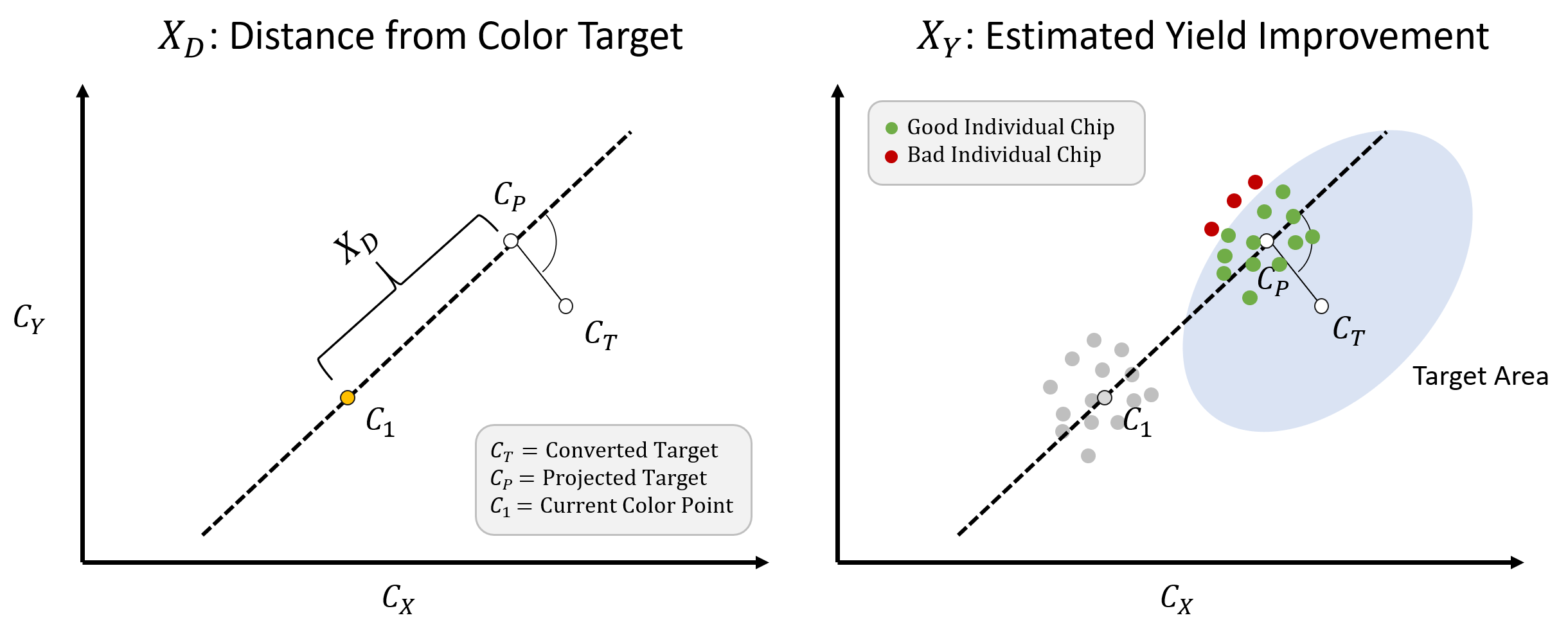

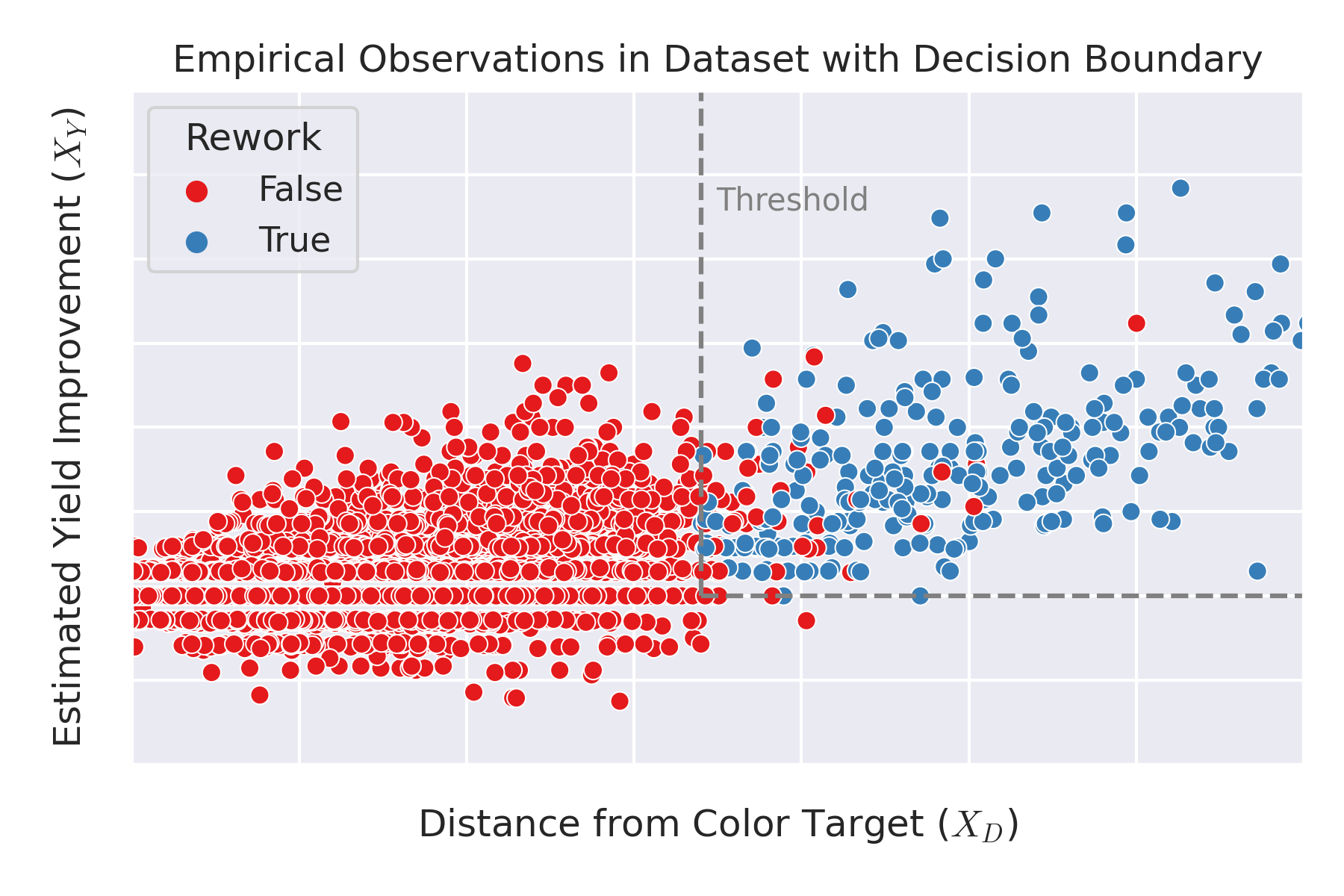

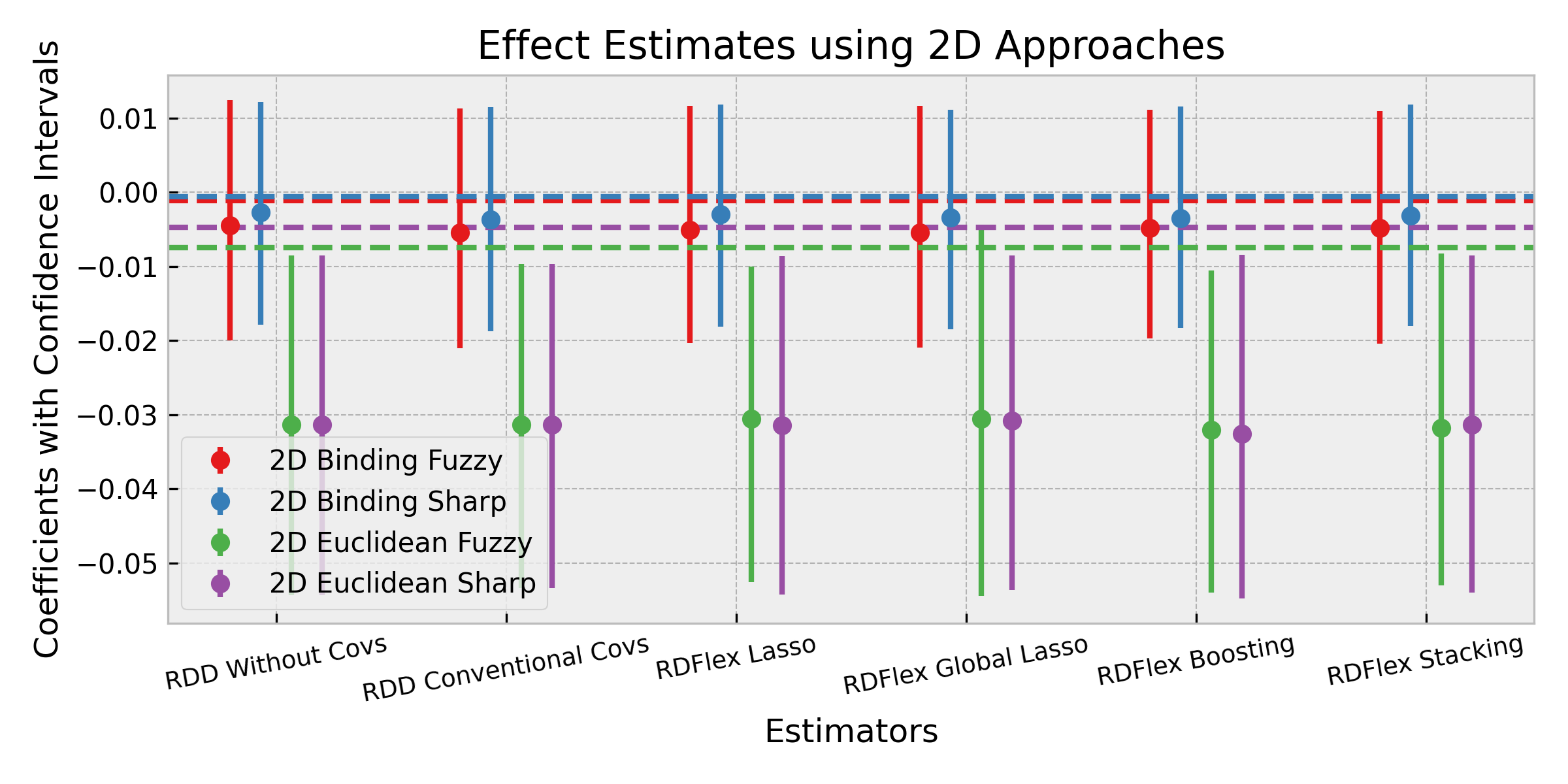

Abstract: The RDD (regression discontinuity design) is a widely used framework for identification and estimation of causal effects at a cutoff of a single running variable. Practical settings, in particular those encountered in production systems, often involve decision-making defined by multiple thresholds and criteria. Common MRD (multi-score RDD) approaches transform these to a one-dimensional design, to employ identification and estimation results. However, this practice can introduce non-compliant behavior. We develop theoretical tools to identify and reduce some of this "fuzziness" when estimating the cutoff-effect on compliers of sub-rules. We provide a sound definition and categorization of unit behavior types for multi-dimensional cutoff-rules, extending existing categorizations. We identify conditions for the existence and identification of the cutoff-effect on complier in multiple dimensions, and specify when identification remains stable after excluding nevertaker and alwaystaker. Further, we investigate how decomposing cutoff-rules into simpler parts alters the unit behavior. This allows identification and removal of non-compliant units potentially improving estimates. We validate our framework on simulated and real-world data from opto-electronic semiconductor manufacturing. Our empirical results demonstrate the usability for refining production policies. Particularly we show that our approach decreases the estimation variance, highlighting the practical value of the MRD framework in manufacturing.

Collections

Sign up for free to add this paper to one or more collections.

Paper Prompts

Sign up for free to create and run prompts on this paper using GPT-5.