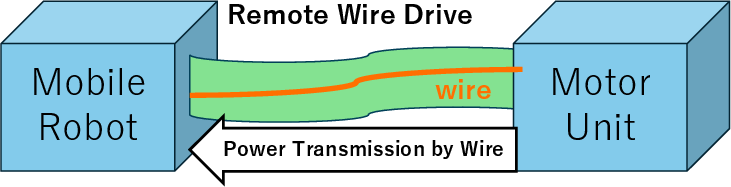

- The paper introduces a Remote Wire Drive system that centralizes actuation in a protected unit to enable electronics-free operation in hazardous environments.

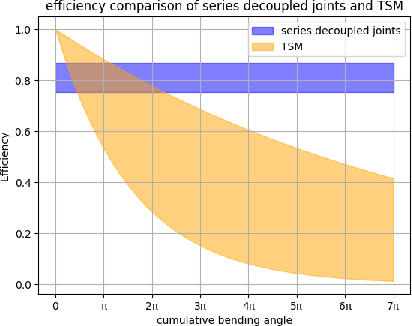

- The decoupled joints design maintains high and constant efficiency (75–87%) by minimizing friction via low-friction pulleys, outperforming traditional tendon sheath mechanisms.

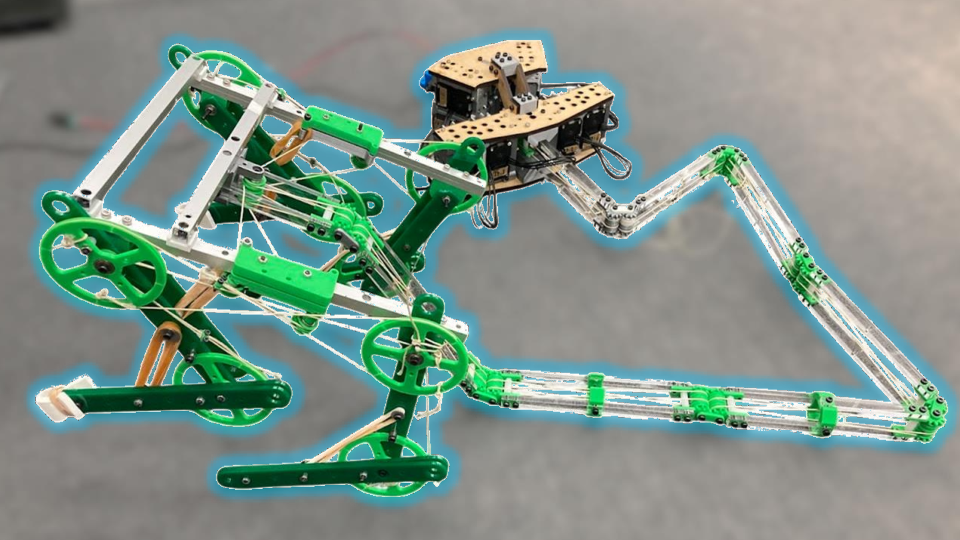

- Experimental validation with a quadruped robot demonstrates practical gait execution and potential for applications in disaster response and nuclear decommissioning.

Design and Development of a Remotely Wire-Driven Walking Robot

Introduction and Motivation

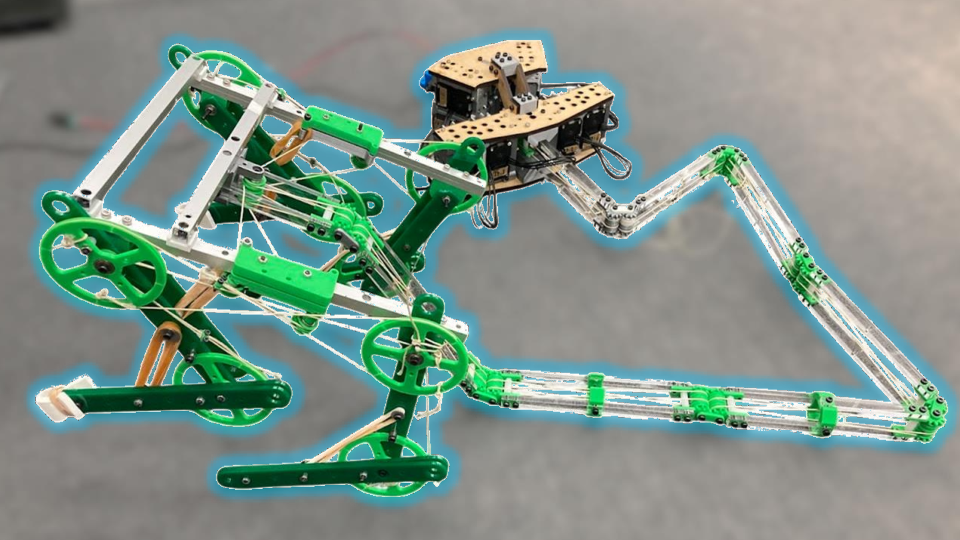

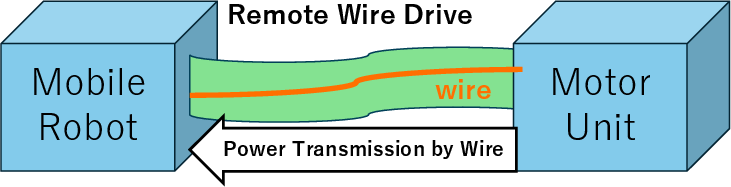

Robotic operation in hazardous or inaccessible environments necessitates actuation and control architectures that are robust to environmental extremes such as high humidity, radiation, temperature, and chemical exposure. Traditional mobile robots, which rely on onboard electronics, are vulnerable in such settings. While electronics-free robots and hydraulically actuated systems have been explored, each approach presents significant trade-offs in terms of complexity, environmental compatibility, and behavioral sophistication. The present work introduces a novel actuation paradigm—Remote Wire Drive—enabling remote, electronics-free actuation of mobile robots via a mechanically decoupled, wire-driven transmission. This system is experimentally validated on a custom quadruped robot, demonstrating the feasibility of efficient, flexible, and robust remote actuation for mobile platforms.

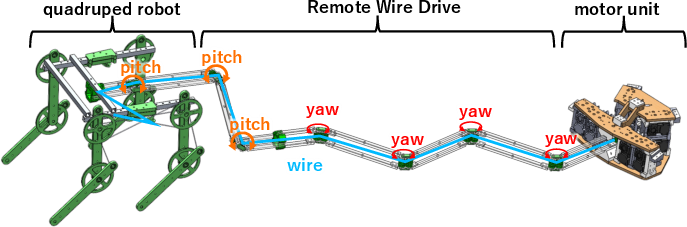

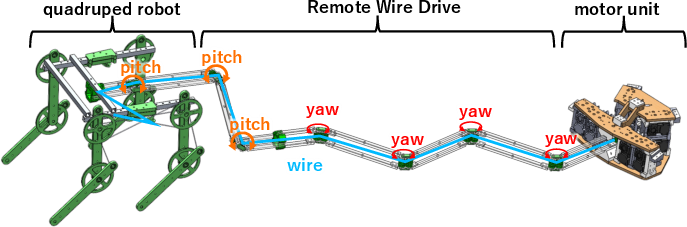

Figure 1: Overview of the remote wire-driven robot, showing the motor unit, Remote Wire Drive, and quadruped robot.

Remote Wire Drive: Architecture and Mechanism

System Overview

The Remote Wire Drive system centralizes actuation in a protected motor unit, transmitting mechanical power via synthetic fiber wires (Vectran) through a series of passively bending, serially connected decoupled joints to a distal mobile robot. This configuration allows the mobile platform to move freely, unconstrained by the transmission path, and without the need for onboard electronics.

Figure 2: Overall structure of the robot system, highlighting the routing of wires from the motor unit through the Remote Wire Drive to the quadruped robot.

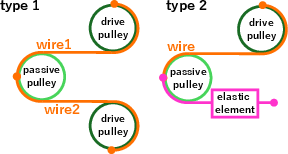

Decoupled Joint Transmission

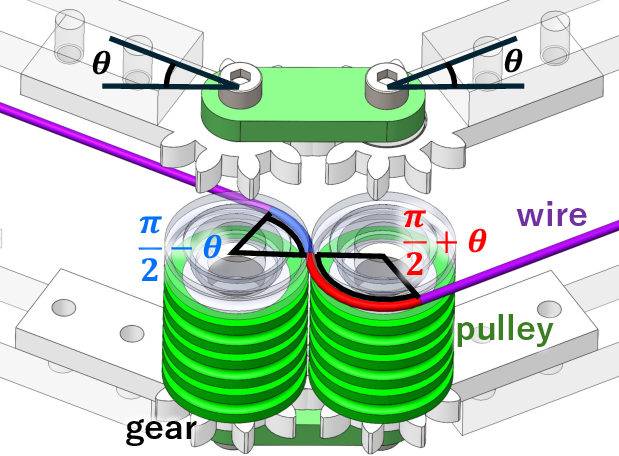

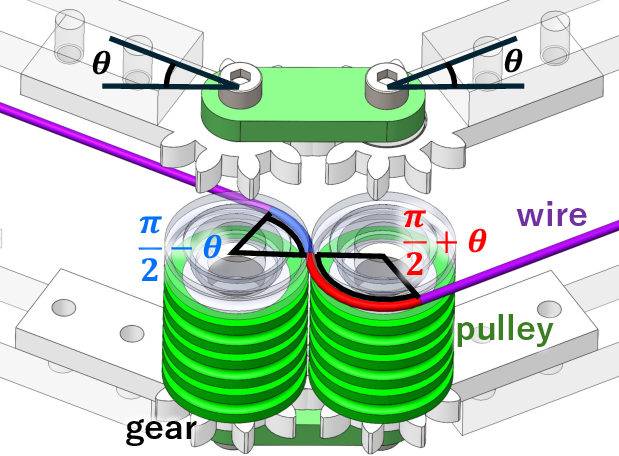

A key innovation is the use of serially connected decoupled joints, as opposed to conventional Tendon Sheath Mechanisms (TSMs). In a decoupled joint, the sum of the wire wrap angles remains constant regardless of joint configuration, ensuring that joint displacement and wire displacement are independent. This property eliminates the mutual coupling that would otherwise restrict the robot's mobility and simplifies the control of distal actuation.

Figure 3: Concept of Remote Wire Drive, illustrating the mechanical power cable analogy.

Figure 4: Structure of decoupled joint, showing independence of joint and wire displacement.

Efficiency Analysis

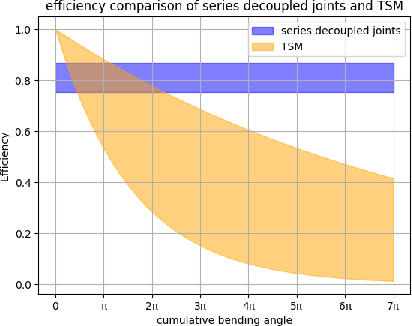

Transmission efficiency is a critical metric for remote actuation. TSMs suffer from exponential efficiency degradation with cumulative bending angle due to frictional losses. In contrast, the decoupled joint approach maintains high and nearly constant efficiency, as all wire redirection occurs via low-friction pulleys. For the implemented system, with a pulley-to-wire diameter ratio of 15 and 14 pulleys in series, the overall efficiency is estimated at 75–87%, significantly outperforming TSMs under comparable conditions.

Figure 5: Efficiency ranges of series decoupled joints and TSM as a function of cumulative bending angle.

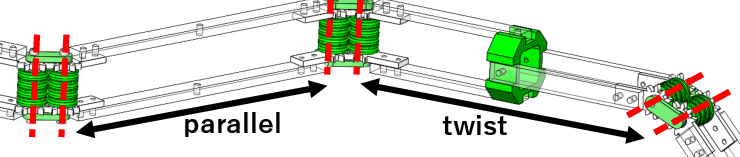

Three-Dimensional Compliance

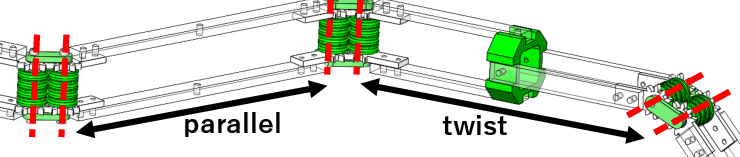

The Remote Wire Drive employs two link types—parallel and twisted joint placements—enabling three-dimensional compliance and a wide range of end-effector motion, not limited to planar trajectories.

Figure 6: Link types for serial decoupled joints, supporting 3D movement.

Quadruped Robot: Design and Control

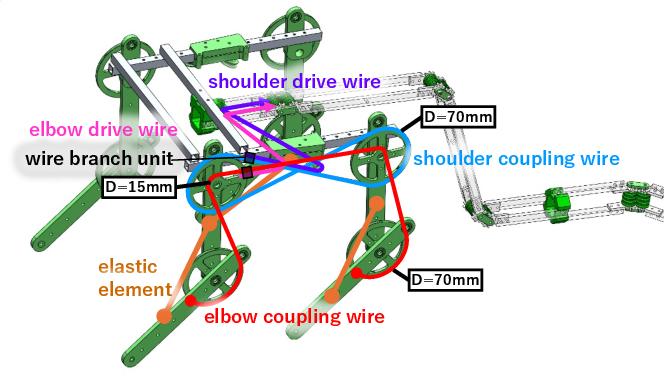

Wire-Driven Leg Architecture

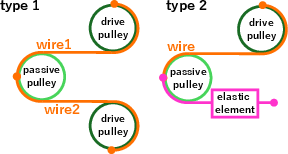

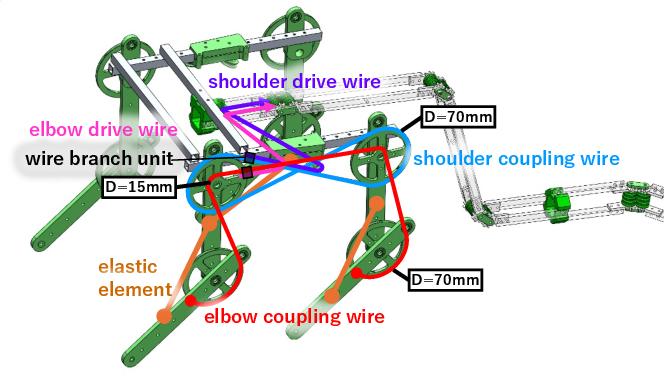

The distal robot is a quadruped with eight degrees of freedom, realized via four wire pairs (two per side) and antagonistic elastic elements. The drive method is a single-wire/elastic antagonism, minimizing the number of wires and the cross-sectional area of the transmission.

Figure 7: Classification of drive methods in wire-driven systems.

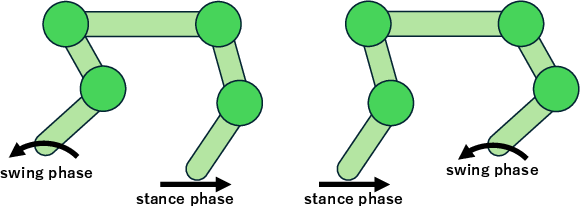

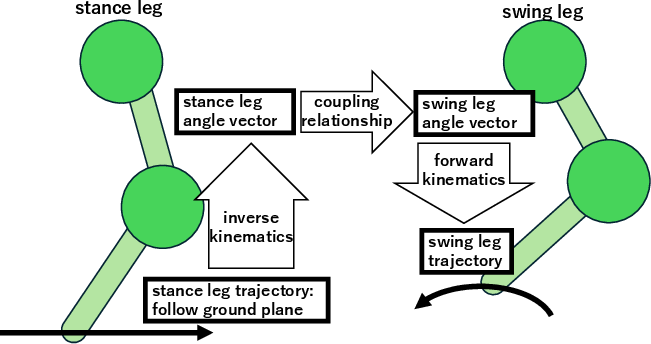

Gait Planning and Kinematic Coupling

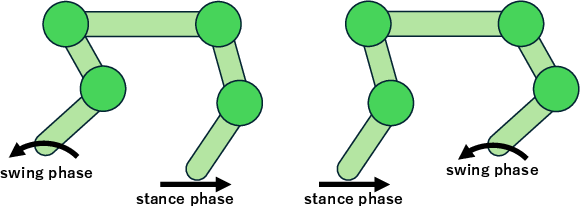

A trot gait is implemented, with front and back legs coupled in opposite directions. The wire layout ensures that the same wire displacement actuates both front and back legs, with the coupling realized via a wire branch unit. The antagonistic elastic elements maintain constant tension, compensating for slack and minor elongations.

Figure 8: Cycle of the trot gait, showing alternation of swing and stance phases.

Figure 9: Wire placement of the robot, with front and back shoulders and elbows coupled in opposite directions.

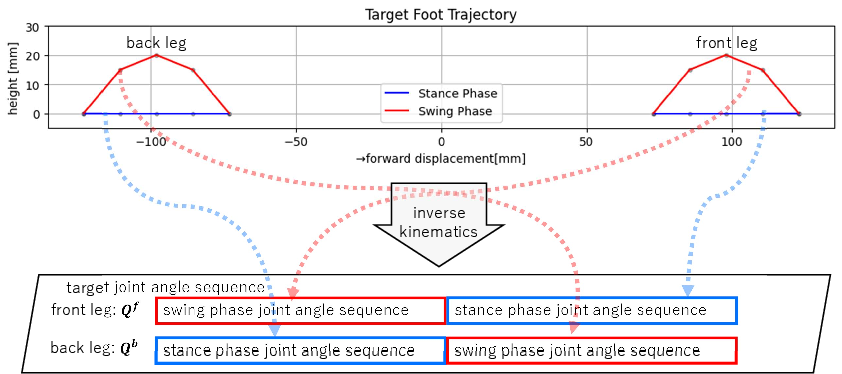

Trajectory Optimization

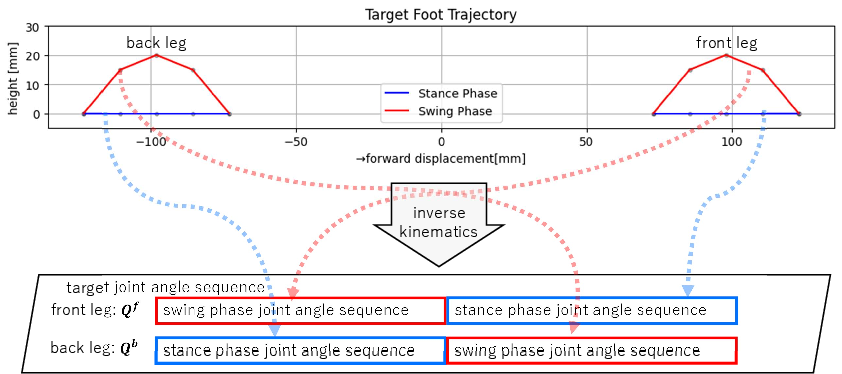

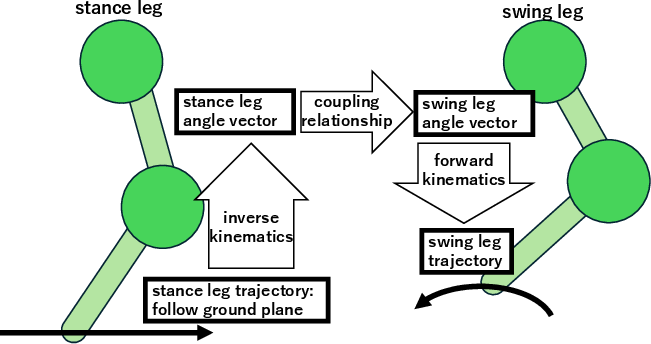

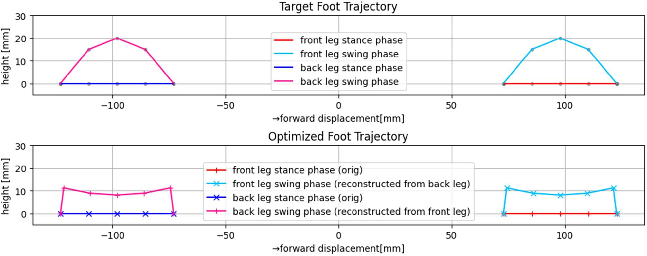

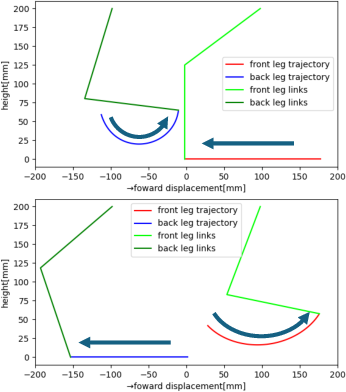

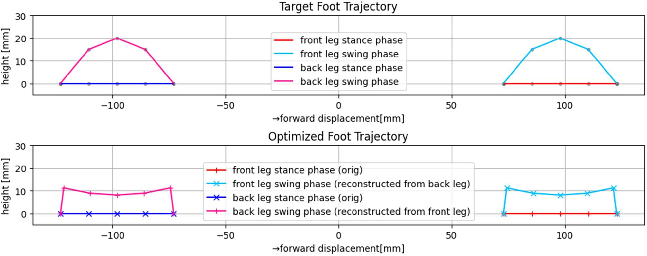

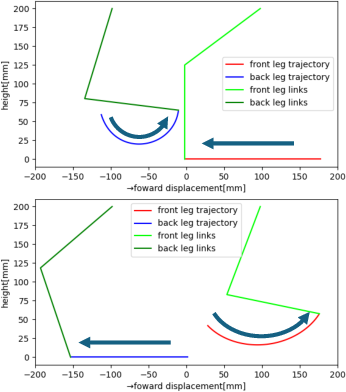

The leg trajectories are computed to approximate an ideal comb-shaped foot path, subject to the constraints imposed by the wire coupling. The optimization minimizes the deviation between the achievable and ideal trajectories, with constraints on the tendon Jacobian to ensure feasible and manufacturable pulley arrangements. The resulting joint sequences are derived via inverse kinematics for the stance leg and forward kinematics for the swing leg, ensuring ground clearance and proper gait phasing.

Figure 10: Target joint sequence calculated from the target foot trajectory.

Figure 11: Method of calculating the swing leg trajectory from stance leg trajectory and coupling constraints.

Figure 12: Target foot trajectory and optimized foot trajectory, showing close approximation within coupling constraints.

Figure 13: Foot trajectory plan, with stance following the ground plane and swing calculated from coupling.

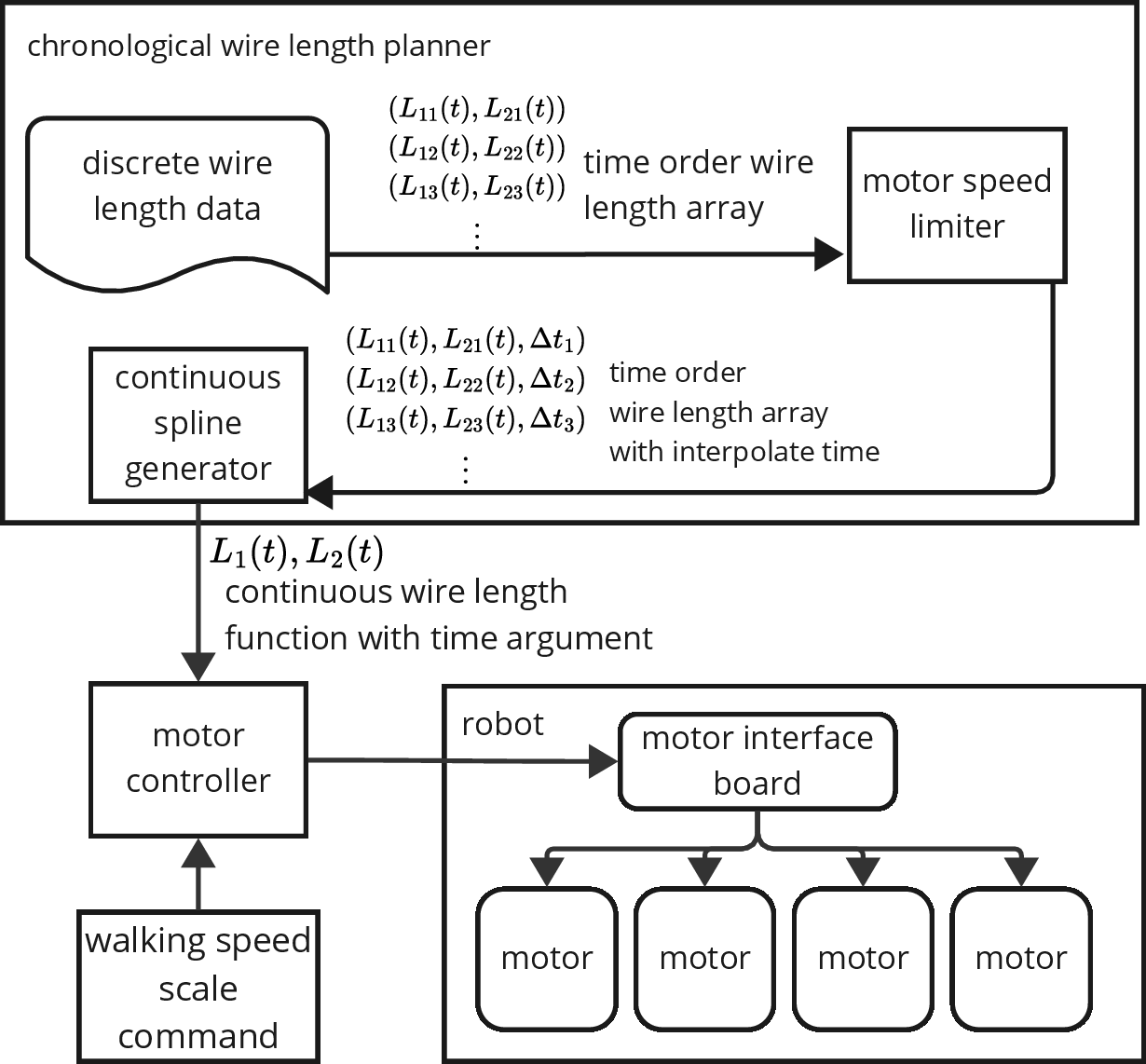

Control Pipeline

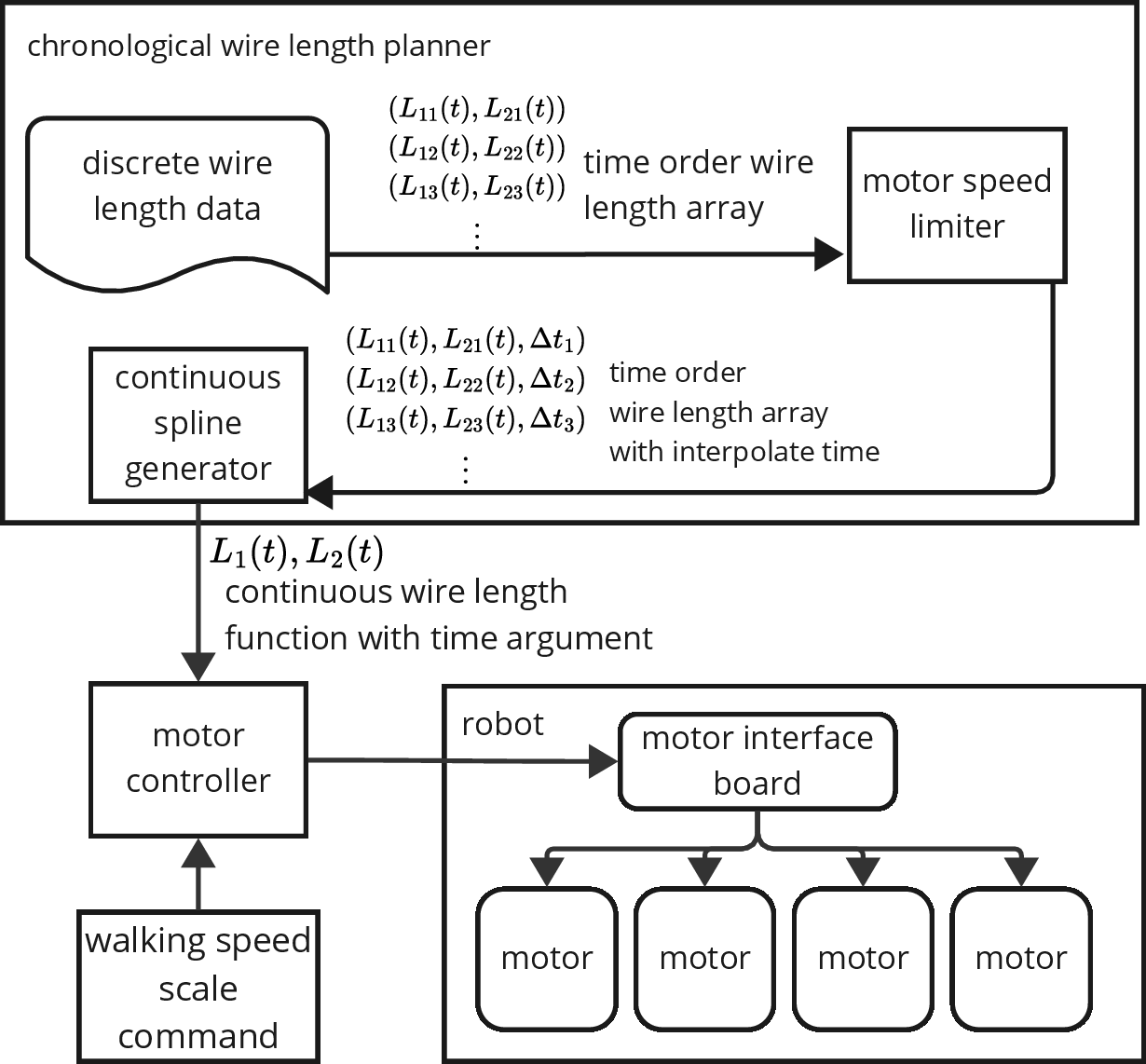

The time-series of wire displacements is generated from the optimized joint trajectories. To ensure actuator velocity limits are not exceeded, time interpolation and spline fitting are applied, and the resulting continuous trajectory is time-scaled before being sent to the motor controllers.

Figure 14: System of the robot, from trajectory generation to motor command.

Experimental Validation

Midair Gait Execution

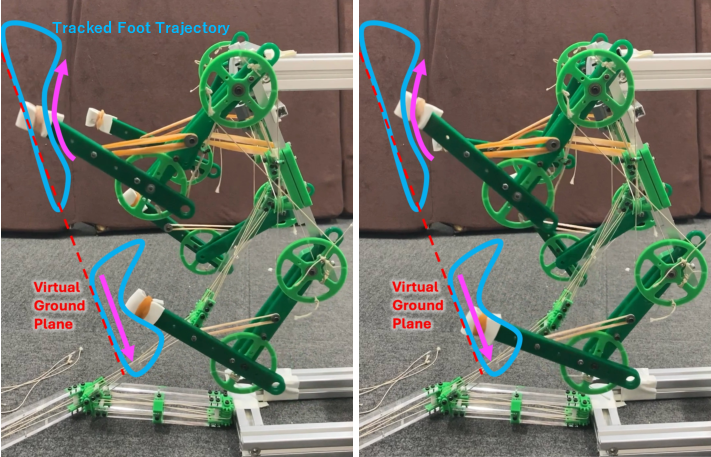

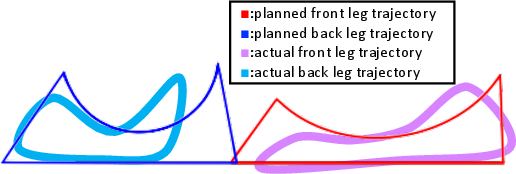

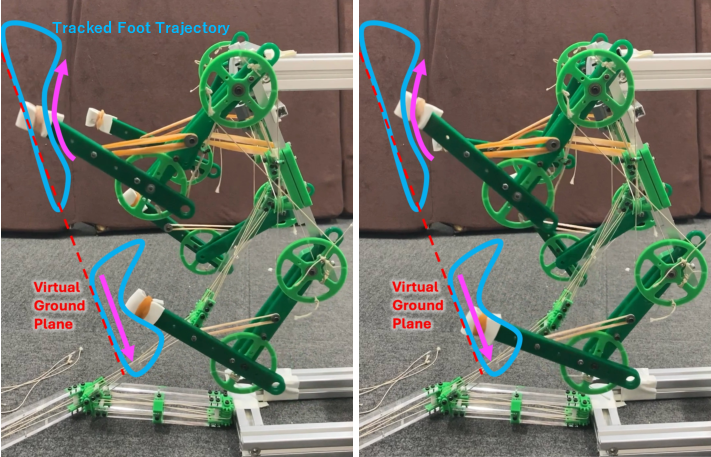

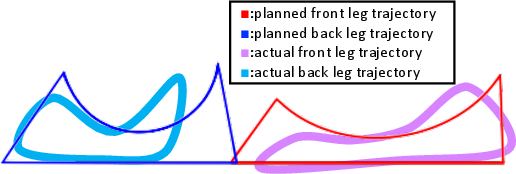

The robot was suspended and commanded to execute the walking trajectory in free space. The tracked leg trajectories closely matched the planned paths, with minor deviations attributed to wire stretch and initial joint angle errors from manual assembly.

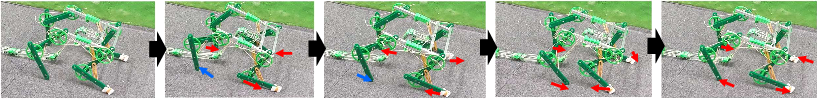

Figure 15: Quadruped robot performing walking motion midair, with tracked trajectories.

Figure 16: Comparison of planned and actual trajectories, showing general consistency.

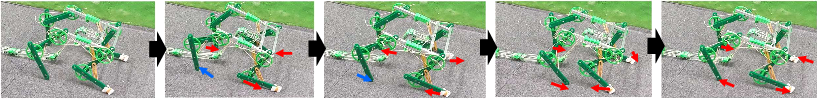

Locomotion on Floor

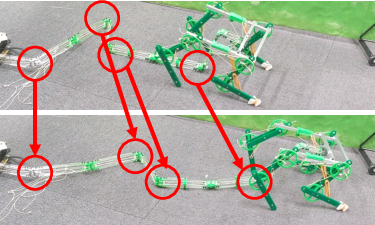

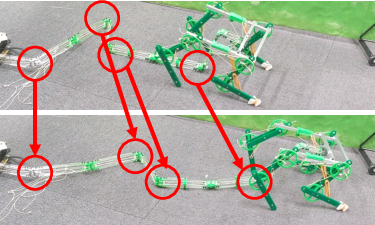

On-ground walking experiments demonstrated that the robot could advance approximately 30 cm in 30 seconds. The configuration of the Remote Wire Drive changed significantly during locomotion, yet the leg behavior remained consistent, confirming that the serially decoupled joint transmission does not impede distal mobility.

Figure 17: Quadruped robot walking on floor, with foot contact and swing phases indicated.

Figure 18: Change in Remote Wire Drive configuration from start to end of walking, with significant joint variation.

Discussion

The experimental results validate the feasibility of the Remote Wire Drive for mobile robot actuation in environments where electronics are undesirable or infeasible. The decoupled joint transmission achieves high efficiency and mechanical compliance, overcoming the limitations of TSMs and rigid conduit-based approaches. However, the system exhibits limitations in locomotion speed and control accuracy, primarily due to wire stretch and the absence of feedback control. The robot's swing legs occasionally dragged on the floor, a consequence of open-loop gait control and the inherent instability of the trot gait without sensory feedback.

Theoretical implications include the demonstration that serially decoupled joints can serve as a general-purpose, high-efficiency remote actuation mechanism for mobile robots. Practically, this architecture is promising for applications in nuclear decommissioning, disaster response, and other domains requiring robust, electronics-free actuation.

Future Directions

Enhancements in wire stretch compensation, friction modeling, and closed-loop control—potentially via remote sensing—could significantly improve performance. Increasing the number of legs or degrees of freedom, and optimizing the mechanical design for specific tasks, may further extend the applicability of the Remote Wire Drive. Integration with advanced materials and miniaturized actuation units could enable deployment in even more challenging environments.

Conclusion

This work establishes the Remote Wire Drive as a viable architecture for remotely actuated mobile robots, leveraging serially decoupled joints to achieve efficient, flexible, and robust power transmission. The experimental quadruped robot demonstrates the practical implementation and operational feasibility of this approach. While current limitations exist in speed and control precision, the architecture provides a foundation for future development of mobile robots capable of operating in extreme environments without onboard electronics.